High demand for machines in manufacturing sectors ranging from automaking to packaging will push the industrial machinery market to new heights during the next five years, highlighted by a doubling of growth this year, according to a new report from researchers at IHS Technology.

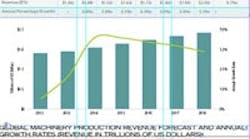

As economic conditions continue to improve worldwide, the demand for machines in sectors such as agriculture, packaging, materials handling and machine tools will push revenues to $1.6 trillion this year, up from $1.5 trillion in 2013. This represents annual growth of 6.3%, more than twice the 2.9% increase seen in 2013.

Strong growth is forecast to continue for the next four years, with revenue rising to $2.0 trillion by 2018 (see page 22). During this period, the machinery market's annual growth rate will remain quite impressive, averaging between 5% and 6%.

Chemineer has been chosen by Cynar PLC as its engineering partner for agitation at the U.K.'s first waste plastic-to-diesel plant at Avonmouth near Bristol. The end-of-life plastics-to-diesel (ELPD) facility is the first of a multi-plant project that will be established across sites in the U.K. Chemineer will supply agitators for other planned sites in the U.K. and Europe.

ABB's robotic division made a gift of $50,000 to the Oakland University (OU) School of Engineering, in support of the school's development of a four-year industrial robotics and automation program.

Real-Time Innovations, a real-time Internet of Things communications platform company, became an initial member of the Industrial Internet Consortium (IIC). The goal of the IIC is to accelerate the development of connected industrial applications