Hallite Seals Americas and the Milwaukee School of Engineering Fluid Power Institute have developed a new methodology for measuring dry particles that are a major cause of hydraulic system inefficiency, degradation and failure.

The problem is a straightforward one. Most hydraulic systems employ cylinders that function like a syringe, drawing in contaminants. The rod wiper located in the sealing configuration of a hydraulic cylinder is designed to limit these contaminants. However, there is no specific ISO method for testing a rod wiper’s ability to prevent >4, >6 and >14-micron particles from entering the hydraulic system. These microscopic particle sizes are most damaging to hydraulic systems as referenced in ISO 4406 for coding contamination levels.

The MSOE rod wiper test uses an online particle counting method instead of the traditional gravimetric measurement method, where particles are weighed. Chuck White, business development manager for Hallite, explains, “The particle count approach provides a more complete and accurate assessment of contaminants than weight because two samples can have the same gravimetric weight in oil, but one may contain many more dirt particles than the other, indicating much greater potential for damage to precision components. This new method raises the bar on keeping solid contaminants out of the system now to avoid problems later.”

Prior to this project, the only standardized test to assess contaminant exclusion of rod wipers was SAE J1195. Though some of the elements of SAE J1195 were valid to replicate hydraulic cylinders, key components were missing that provided valid conditions to assess the effectiveness of a rod wiper.

In the new test, MSOE used the SAE J1195 standard combined with best practices to establish a baseline for developing the rod wiper test procedure. A rig was built in the MSOE test lab and parameters such as duration, cycle rate, pressure and temperature were set using input from hydraulic cylinder manufacturers to best simulate the rigor of actual field conditions. It took eight months of development, verification, trials and adjustments to establish a repeatable test procedure.

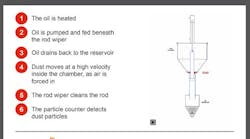

The test procedure involved installing the rod wiper into the specified test fixture, heating the hydraulic circulation fluid to150˚F, pumping the oil over the top of the rod and letting it drain down into the reservoir while circulating high-velocity particles (ISO 12103-1-A4 Course Test Dust) of contamination in the chamber. The objective was to count how much dirt and grit got past the wiper.

The test rig had the following rod wiper ingression test parameters:

- Test duration – 24.000 cycles (80,000 linear feet travel)

- Cycle rate – 0.25 Hz (10 to 10.5 inches per second)

- Stroke length – 40 inches total

- Test pressure – Atmospheric

- Test Temperature – 150 degrees F +/- 2 F

- Test Oil – MIL-PRF-46170

- ISO 12103-1-A4 Course Test Dust

The test rod wiper was installed in the rod end of the cylinder housing along with a TPE-faced, two-piece rod seal (Hallite Type 16 profile) to simulate typical boundary lubrication that is found on the rod in standard cylinder application. The hydraulic circulation fluid was heated to 150 °F by heaters located in the reservoir and was circulated with the cylinder rod fully retracted (not cycling) until the temperature was achieved. The rod was then cycled through the dust chamber for the duration of 80,000 linear feet and dirt content measured in the oil reservoir via the particle counter.

White says that this new test procedure enables the highest level of accurately assessing and measuring dry dirt ingression available. He calls is “a major leap forward, establishing a repeatable pattern for the industry’s innovation of future test methods focused on wiper technologies used in a wide variety of real-world operating environments.”