"UltraMelt overcomes some of the unique challenges presented in injection molding for thermally sensitive materials which are also sensitive to the melt-contact surfaces of the melt channel network," explains Derrick Hennebicque, product manager, hot runners, at Husky.

UltraMelt specifically addresses these challenges with non-reactive surfaces and stainless-steel components to preserve the sensitive chemistry of bioresin materials and minimize degradation. UltraMelt was introduced to the marketplace in 2022, becoming a pioneering solution for bioresin melt delivery.

"UltraMelt hot runners utilize high-end aerospace materials in their construction," says Hennebicque. "Its capability has been studied in several configurations, applications and processing scenarios to ensure robust performance when molding various parts for several markets."

The unique design gives UltraMelt its innovative performance. "Husky’s UltraMelt hot runners feature thermocouples for precise temperature monitoring to ensure careful thermal management," notes Hennebicque. "This ensures the resin flowing through the melt network is not overexposed to heat during its journey from the injection molding machine’s barrel to every mold cavity. This also ensures the resin is not exposed to underheated areas, which could present high-viscosity areas causing pressure spikes by increasing viscosity."

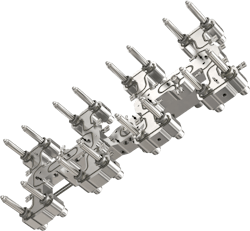

Husky’s UltraMelt hot runners can be built to accommodate hot-tip and valve-gate nozzles, explains Hennebicque (Figure 3). "Any kind of valve stem actuation can be implemented, depending on the application and mold’s cavity layout," he notes.

“On behalf of the Husky team I would like to thank you, the Plastics Industry Association, for this prestigious honor,” says John Galt, CEO of Husky. “Bioplastics, together with advancements in circular polymer processing, are key parts of Husky’s sustainability strategy. We are convinced that by working together as an industry we will turn challenges into opportunities. We will demonstrate that the circular economy is not just a buzzword but a reality.” Polymers preserve and protect more effectively than any other substrate, Galt continues. “They can be formed into an infinite number of shapes and sizes,” he explains. “They are lightweight and unbreakable. They have the lowest overall environmental footprint. They keep consumer costs down. Investing and working together to building truly circular solutions is good for our industry, for our children and the planet.”

A formal presentation of the Bioplastics Innovation Award will be made on the Sustainability Stage at NPE2024: The Plastics Show, which will take place May 6-10, 2024, in Orlando, Florida.

Plastics Industry Association member companies interested in submitting innovations for consideration in the 2024 Innovation in Bioplastics Award competition can look forward to the opening of the submission window in May 2024.

Established in 1937, the Plastics Industry Association supports the entire plastics supply chain, including equipment suppliers, material suppliers, processors and recyclers.