Case Study: University builds nanofiber-producing machine for biomedical research

If you can’t buy it, you have to build it. This was the situation we encountered when we needed to grow vascular tissue for a bioengineering project at our university, and we found existing solutions not acceptable. In addition to our team, others needed the machine for their research projects, which provided additional motivation.

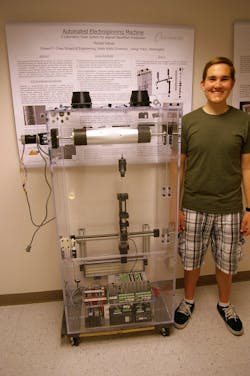

We built a new machine to meet our needs, and anyone involved in tissue engineering or biomaterials research at a university or a biotech company might find our nanofiber production or electrospin machine particularly useful (Figure 1).

Figure 1: The electrospin machine was designed and built by Michael Rafuse as his senior design project at Walla Walla University.

The electrospin machine is located at Walla Walla University (WWU), a private university founded in 1892, and home to the Edward F. Cross School of Engineering. The construction of the electrospin machine was initiated by Michael Rafuse, a graduate of WWU. The machine was his senior project, and he did the majority of the mechanical and automation system design, build and commissioning of the machine. I installed the operator interface, programmed the motion system and operator interface, and I performed some experiments to optimize the machine for our polymer solutions.

Build instead of buy

Although a similar machine existed at our university, it had some safety issues, and the final product was often not satisfactory. This was likely due to the precursor machine using a gravity-fed, instead of a pump-driven, system. Rafuse designed the new machine to address these issues and to provide additional functionality, including a variety of adjustable process parameters.

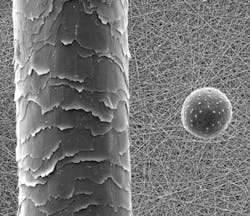

This is not a new process. Electrospin machines are widely used among the research community for producing fiber mats for culturing cells. These mats consist of tiny polymer nanofibers, each mere nanometers in diameter, which mimic the human extracellular matrix by providing a 3D structure, called a scaffold, where cells can grow into human tissue (Figure 2).

Figure 2: The human hair on the left and the pollen grain on the right highlight how small nanofibers, shown in the background, actually are.

The electrospin machine is used to make these scaffolds, which are then used to fabricate tissue engineered vascular grafts.

This process is not only used in tissue engineering and biomaterials research, but also on very different and much larger scale machines in the textile industry. But, in our case, differences are driven by the need to make nanofiber scaffolds.

Scaffold construction

The electrospin machine uses a rotating drum collector to create a biocompatible aligned nanofiber mesh. Features include a syringe and needle automatically positioned in horizontal and vertical directions and a tube-free syringe pump. The machine provides a safe and simple interface for operation and can be quickly modified as required.

Electrospinning requires high voltage, a grounded collection surface and a polymer solution to produce fibers as small as nanometers in diameter. The polymer solution is loaded into a syringe with a blunt-tip needle and a high-voltage electrode is attached to the metal tip. The syringe is a set an adjustable distance, typically 20 cm, away from a collection surface.

The collection surface is a rotating drum that is connected to an electrical ground. When the high-voltage source is turned on, it creates an electric field that induces a charge in the polymer solution, and repulsion forces propel the polymer solution toward the grounded collection surface. As the polymer flies through the air, the solvent evaporates and leaves a fine fiber that is mostly dry when it reaches the collection surface.

A two-axis gantry configuration holds the needle and is positioned using stepper motors. One stepper motor is used to control the vertical distance between the collection surface and the needle tip, and a second is used to control the horizontal position of the tip. A third stepper motor is used to control the extrusion rate of the polymer solution flowing through the needle tip. The collection-surface rotating drum is the fourth axis of the machine, and it is spun at speeds up 4,000 rpm using a brushless dc motor.

Machine control components

The main automation system components are all AutomationDirect products and include a Productivity 2000 PLC-based programmable automation controller, a C-more EA9 series 10-in touch panel human machine interface (HMI) and SureStep stepper motors and drives. The controller, HMI, stepper motion control and related linear actuators enable precise and configurable control of the electrospinning process. AutomationDirect’s Rhino power supplies (5 V, 12 V and 24 V), GCX series selector switches and pushbuttons and ECX series indicator lights were also used.

The controller has five communication ports including USB and Ethernet and can control up to 480 local I/O points. We programmed it using AutomationDirect’s free Productivity Suite programming software. This software allows user-defined tag-based programming for easy I/O naming, and it provides task-based organization of ladder logic code. The electrospin process is primarily viewed and adjusted using the HMI. Several buttons, switches and indicator lights are also provided for control and status indication (Figure 3).

Figure 3: Peripheral devices such as the HMI were added to the electrospin machine to provide additional control and monitoring functions.

To stay within our budget, campus resources including machine shop equipment, 3D printing and manufacturing lab surplus components were used when possible. In addition, a number of companies were very generous in providing support in the form of part donations.

Also read: Case Study: Harry Major Machine modern gantry improves plant uptime, recovery

Variable electrospin control

Many of the variables affecting the process and resulting fiber production are adjustable via the HMI. Variables need to be finely tuned to create consistent nanofibers with a particular surface morphology to meet research or application requirements. The rotating drum collector speed, needle positioning and syringe pump are the critical systems. Closely monitored and controlled and commonly modified variables include collector surface speed, needle-to-collector distance, polymer solution flow rate and high voltage level.

The rotating drum collector provides an electrically earth-grounded surface for aligned nanofiber collection. By varying the drum rotation speed, its surface velocity can be varied to match the velocity of fibers as they are deposited on its surface, resulting in fiber alignment.

The drum collector is rotated using a brushless dc motor and drive. Drum speed is set by a 0-5 Vdc analog output from the controller, and direction is controlled via a discrete output. Speed control is closed loop, with feedback provided by hall-effect sensors. Drum starting and stopping, along with speed adjustment, is provided using the HMI.

Needle positioning can be varied using the horizontal belt drive and vertical screw drive slide table systems. Stepper motors power the slide tables and provide precise positioning control for horizontal and vertical movement. Horizontal and vertical travel distances are 50 cm and 25 cm, respectively.

The distance from the needle to the collection surface is one of the most significant variables in the electrospinning process. Position of the needle is controlled using a high-speed output module. The controller sends step and direction commands to the micro stepping drive controlling the motor. The HMI is used to set needle horizontal and vertical position. The high voltage delivered to the needle is controlled by a 0-5 Vdc analog output which can be adjusted via the HMI.

The syringe pump is the third critical system, and it consists of an electrically isolated syringe mount with precision adjustable flow rate control using a stepper motor and linear actuator. It is attached to the vertical screw-driven needle position slide.

The syringe pump uses a stepper motor and linear actuator to precisely control plunger movement, and end-stop switches are installed in the linear actuator. Syringe flow rate is controlled using step signals sent from the controller to the stepper drive. Its position is controlled using the HMI input, and flow of the polymer solution is adjusted to maintain a droplet at the needle tip for uniform fiber deposition.

Reducing hazards

Safety risks related to high voltage, grounding, fume hazard and coronal discharge were carefully reviewed. The electrospinning machine operates at voltages up to 30,000 Vdc. Although the output current is only 400 µA at this voltage, below the hazardous shock threshold, the electrospun fibers are highly charged, so the machine is protected with an acrylic guard enclosure.

The polymer solutions often include volatile or toxic solvents. Two ventilation fans in the top of the machine guarding and a filtered air-intake vent provide efficient removal of these fumes.

Careful grounding was required to ensure the collection surface, fibers and needle didn’t build up excessive electrical charges. Static charge buildup was eliminated by grounding all fiber collection surfaces to the main 120 Vac supply ground point. Coronal discharge due to a charge buildup was a concern, so a lock was added to the guard door. The door wouldn’t unlock until the high voltage is turned off and the needle is properly grounded.

Final results

My part in the project included wiring of the peripheral equipment, controller programming and related tasks. Some mechanical fine tuning, primarily balancing of the rotating drum, made the machine operational. I then spent much of my time refining the stepper motor control logic and optimizing the electrospin process parameters. After taking the time to learn how best to operate the control system, and with some persistence, we’ve been running the equipment successfully since spring of 2016.

The benefits of the new machine are significant and measurable. Larger and thicker fiber mats can now be produced, and our production rate has thus increased. The machine can also be modified to test different collection methods. With extensive testing of the machine in progress, much more fiber will be produced in the near future.

Images courtesy of Walla Walla University

Latest from Electromechanical

Leaders relevant to this article: