A Control Design reader writes: Whenever I get together with family or friends, they seem to have this science-fiction idea of the robots in our packaging lines. Most of our robots are Delta for pick-and-place robots, but we have quite a few articulated and SCARA robots, none from the same manufacturer. Can we somehow mobilize these? Add in artificial intelligence, and we could have batch-size-one operations. Is this even doable, or have I been spending too much time with my non-engineer family and friends?

Answers

Highly repetitive to adaptive tasks

If we try to explain robotic automation to a family member, they often imagine sci-fi images of mobile humanoid robots that are here to take over our jobs or the world. In reality, the robots we use are much tamer. And, in terms of their appearance, current mobile robots used in industry resemble more of a flat moving table or shelf, rather than those humanoid visions.

Also read: Autonomous mobile robots’ value is more than just speed

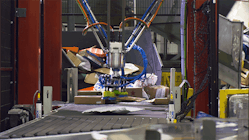

Figure 2: This type of sorter application is common in parcel distribution centers, in which disorganized bulk flow comes in, and it must be arranged properly, single-file stream, for downstream automation processes.

Historically, robots were used for automating highly repetitive tasks. But the industry needs to automate slightly more complex, adaptive tasks, such as picking from a bin or navigating in a warehouse. Many companies are attempting to do that by leveraging cameras, proximity sensors, artificial intelligence (AI) and powerful computation. Cameras have been coming down in price and size, and computing power has also been increasing—following Moore's law of exponential increases in computing power while becoming smaller and decreasing in price. The last ingredient is the AI models running on the compute units. Heavy investment in talent and technology has produced new AI models that are more accurate to the point that the accuracy of some object-detection models even surpasses human ability.

However, there is still work to be done to integrate all these components and adapt them to specific tasks or customer needs. Each of the components carries an inherent possibility of error or failure, which increases when they are integrated as part of a solution for a task. And, when designing a solution in a lab, engineers often make assumptions about the problem, but often when the robotic solution is taken to the field, exception cases occur, either degrading the performance, stopping the robot or, in the worst case, causing damage to items they are handling.

With all that said, there are areas where automation is making great strides. For example, during the past four years a robotic system has been developed for singulating parcels from bulk flow to a single-file line (Figure 1), a common task in the express courier industry. While about 99% of what the customer might encounter is not a challenge for the system, the hard work comes when handling the remaining 1%—those exception cases like extra-large parcel boxes, extra heavy boxes and odd-shaped parcels, like cylinders and spheres. For instance, a special robotic end-effector has been designed to grab packages using vacuum suction (Figure 2), but some boxes have holes. Experience with that 1% is not unique—it’s the nature of the beast. Humans are great at handling exceptions, and human hands are the world’s best end effectors. Robotics are a long way from completely automating most facilities, but the technology is automating dull, repetitive tasks, with humans supporting when needed, and it’s getting better every day at handling the 1% exceptions.

Kristiyan Georgiev / R&D software engineering manager / MHS / www.mhsglobal.com

Open communication between robots

I find it actually inspiring to be with family and friends who bring up automation. Their wonder about what could be can help us to think outside some very thick walls we have built around ourselves. By their nature, articulated and SCARA robots sit in a fixed point but with the ease adding them to a driving base they easily become an autonomous mobile robot (AMR). The fact that they are from different manufacturers is not of concern. Each robot has its core controller, but the overall control system could easily be handled through OPC-UA simultaneously not interfering with the core. Because you are using smart technology on the systems, it is very simple to accomplish batch-size-one for all robots. The parameters can be set so that each unit has the same work parameters and is ready to start just by feeding it the program. Not only is this doable, it is ready to be done.

Perry Hudson / key account manager—packaging / Pepperl+Fuchs / www.pepperl-fuchs.com