A Reader Writes:

Until recently, for better or worse, we used screw-clamp terminal blocks for connections. Now, we have customers that prefer and sometimes specify insulation-displacement connectivity. They argue IDC means lower installation costs and reduced cabinet space as a result. That's fine, but I'd like to hear what real users know about the increased likelihood of having to run down loose connections in the field later on. We sell into global environments with varying degrees of vibration, repetitive motion, etc.

—From August Control Design

Answers

Use Cage-Clamp When Free to Choose

We have switched to cage-clamp terminals for our unspecified control panels. One of our toughest customers is a road construction equipment builder. We design and fabricate the control panels for them. This equipment is very high vibration and must work in temps ranging from 0-100° F-plus.

Sales reps have been telling us that IDC terminals have improved and are the way to go. We built a test panel to mount on a piece of road equipment. It did not do anything. We just had a few 120 VAC and 24 VDC circuits that had lamps on them. We used both cage-clamp and IDC terminals. At the end of three months, we had an 8% failure of the IDC terminals and a 0% failure on the cage-clamps. At the end of one year, 19% of the IDC terminal connections had failed and 0% of the cage-clamps had failed. By failed, I mean the circuit was open completely or intermittently.

Steve Clayton,

Motor Control Engineering LLC

We're beginning to think it would be good to convert to wiring modules and quick disconnects for our machine control system. There look to be advantages for saving time and money when building the machines, for off-site troubleshooting, and for the customers' ease of reconfiguration. We'd like to hear from machine builders about this. Do the time savings offset the extra costs? Do customers see the value?

Send us your comments, suggestions, or solutions for these problems.

IDC Will Do Fine

We have a considerable amount of experience with our IDC terminal blocks used in industrial environments. The applications range from connections to PLCs and other control systems, marshalling cabinets located throughout the plant, motor control centers, test equipment, HVAC wiring, security and energy management wiring, and local control panels in the plants, to a wide variety of instrumentation.

Regarding where not to locate IDC terminations, the only obvious prohibition would be where the temperature environment would exceed the temperature range of the terminal block, which would be the same requirement of any type of terminal block including screw clamp or spring clamp). The IDC terminal block is designed to meet IEC 947-7-1, the international standard for all IEC types of terminal blocks.

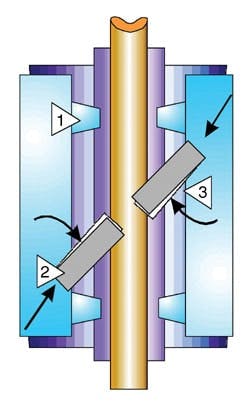

The contact should provide a gas-tight connection, which is necessary to stand up to the environments in an industrial application with corrosion or contact problems, to provide years of reliable operation (2 in figure). The contact should be designed to eliminate any potential damage to stranded wire during wire termination. In the case of our connector, the contact is at a 45° angle to the wire, eliminating any potential problems while ensuring a constant axial force on the wire during the life of the termination (3 in figure). The contact should be made out of a special spring-type copper alloy and should be nickel-plated to provide a high-quality electrical connection and prevent any problems associated with corrosion. The contact should be designed to be reterminated multiple times without deformation to the contact area.

The terminal block should have test reports validating the ability to stand up in areas of vibration, corrosion, and current-carrying capability and should include a wide range of international approvals such as UL, CSA, DEMKO, SEMKO, FINKO, Lloyds, etc.

Howard Minnick,

President,

Automation Systems Interconnect, www.asi-ez.com

IDC Saves Money

IDC technology is designed to save up to 60% of installation time and can be terminated with no special tools or stripping of the conductors. You should look for connections between the contact and the wire to be gas-tight. This ensures a reliable solution over time in harsh environments.

Davis Mathews,

Product Manager,

Phoenix Contact, www.phoenixcontact.com

Think Spring

My perspective comes as a user of terminal blocks and a manufacturer (two different companies) of screw, IDC, and spring-pressure connection technology.

IDC really is designed for unique or very specific applications only. IDC connections are faster to wire, but you can never guarantee a reliable contact.

You are selling into global environments--this means if you are going to use IDC, you must set some stringent rules for your customer base, such as wire insulation type. IDC connections are typically approved for PVC or PE insulation only, such as MTW in the U.S., but not PVC with a nylon jacket such as THHN (which is probably the most common wire insulation found in the U.S.). These wire insulation types/standards vary from country to country.

IDC connections are only allowed to be reterminated X number of times (usually 5-10 times, but this, too, varies depending on which country you sell to). The metal contact, usually a tin-plated copper alloy, does not exhibit good memory, and widens every time you operate the connection. Additionally, IDC technologies that orient the contact vertically from the DIN rail allow the wire to easily be pulled out of the contact.

IDC connections are limited to conductors no larger than 10 AWG. If you need anything larger, you will need to mix technologies, thereby further confusing your customer.

IDC connections are typically larger than the other alternatives available to you. Bigger terminal blocks mean bigger panels and bigger costs.

Despite all the pitfalls, IDC is a viable option if you are dealing with a controlled environment, do not need to rewire connections, are using a PVC or PE insulated wire, do not require a wire gauge greater than 10, and do not need a application-specific terminal block such as a triple tier or sensor/actuator terminal block, etc.

On the other hand, screw-type terminals eliminate many of the pitfalls associated with IDC connections, but they also have their own problems. Screw terminal blocks require more time to wire. They require regularly scheduled maintenance. In a piece of OEM equipment, all screws typically are tightened before shipping to the end user, then the end user must recheck all connections during install and prior to powering up. In addition, preventative maintenance must be performed, as screws vibrate loose, so a plant technician retightens every screw.

Screw terminals also require a specific torque range to be considered installed properly, per the local country's electrical standards committee. Having worked in a plant and visited many plants worldwide, I can tell you very few plants, discrete or process, use torque screwdrivers. This means the torque value on the connection and hence the connection quality can never be guaranteed. Remember a loose connection can be just as problematic as a connection that has too much force applied to it.

The best solution available in the marketplace today is spring-pressure connection technology (also known as cage-clamp). Spring-pressure connection technology reduces wiring time up to 50% compared to conventional screw-type systems. Even more important, because the clamping force adjusts automatically to the wire size (no torque specs required--the contact pressure is pre-programmed in the clamping spring), it provides reliable contact that is virtually independent of operator skill--unlike screw connections, which require torque screwdrivers, or IDC, which requires a controlled environment.

In addition, there are no wire-size restrictions, no restrictions on wire insulation type, no special tools required, no size sacrifice, and no limitation on application-specific terminal blocks. Spring-pressure terminal blocks have been around for more than 25 years and are available in many different styles to solve virtually all wiring applications. In the end you are the one that must be comfortable with the technology you choose.

Dean Norton,

Marketing Manager,

Wago Corporation, www.wago.us

Use Spring-Loaded for Easier Troubleshooting

I have worked in the industrial machine environment for more than 20 years, and have used everything from screw terminals to milspec connectors to insulation displacement. I have found insulation displacement may be quicker to assemble, but if you have to carry out fault-finding and maintenance, then insulation displacement is very difficult to use.

The best compromise I have found is the IEC-style spring-loaded terminal. The terminals are faster to assemble than the screw-type, do not vibrate loose, but are much more field serviceable.

Ray Opie,

Engineering Director,

Solidica Inc., www.solidica.com

Leaders relevant to this article: