[sidebar id="1"

]We periodically investigate portable, operator-interface technology, looking for machine builders who use it. For years we've failed to find more than one or two companies using some form of handhelds. This year there's a little more evidence, an indication that machine builders and the technology are coming around.

Many of you tell us you've looked hard at handhelds, and found them wanting for one reason or another. However, from what we've discovered, many of those fears are unwarranted.

Handhelds just might be one of those "freight train" technologies that catch on, build up speed, and take an entire industry with them. You might want to reconsider handhelds before your competitors beat you to the punch with a big "Wow Factor."

Evidence to Make the Case

Machine builders are using handhelds with varying amounts of success. Ed Ortiz, senior project engineer at Manitex, a builder of cranes, lifting equipment and caerial platforms in Georgetown, Tex., uses handhelds to download data and software into computers installed in his company's cranes. "We use a standard crane computer in all our cranes, and download the appropriate software and data for each model," he explains. "This includes data needed for the load-moment indicator." The handheld isn't offered to the customer because it's used only for initial programming.

Bill Evans, engineer at York, a HVAC manufacturer in York, Pa., also uses handhelds for setup. "We program and set up variable, air-volume cooling boxes," he says. Evans adds handhelds have become a good selling point for York's machines.

On the other hand, Bob Erko, chief engineer at Tennant, a Minneapolis-based maker of floor maintenance equipment, got the opposite result. His salespeople won't sell it. "We started out using PDAs as a data conduit between our machines and a PC," explains Erko. "We also used the PDA as a user interface or programming pendant."

It seems the Palm handheld Tennant chose didn't work out. "It took us a year to develop the product," continues Erko. "By the time we had it developed and were ready to stock PDAs, the device went obsolete. We make a product with a 10-year minimum lifespan. When marketing got wind that the device was going obsolete, it became an impossible sale. The sad thing is that we really could have leveraged the user interface for the good of our customers. Now, if you mention Palm around here, be prepared to dodge incoming daggers. It was easier to sell a complete new system than to convince people the handheld would be a viable, long-term industrial option."

Handheld technology has come a long way from the original Palm computers in a very short time, making them much more useful. Indusoft, for example, claims it has dozens of customers that use handhelds, including machine builders. Indusoft reports most of its customers won't talk about it because the handhelds give them a competitive edge. They told us of two companies that use the technology.

Micron Systems, a builder of process control systems in Houston, uses a Casio PDA as a full-featured operator interface with its multi-loop controller and compressor controls. MCL Control, a builder of safety and control packages in the energy industry, also in Houston, uses the same InduSoft CEView HMI/SCADA software to configure identical HMI displays on its big panel screens and on an H-P iPAC PDA (See Figure 1).

In addition, handheld computers can replace dedicated pendant-type products. For example, robot teaching pendants have long been required in the semiconductor industry. If pendant suppliers discontinue them, robot users could be in trouble.

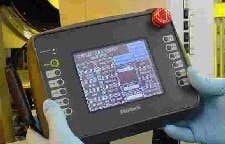

Bill Jones, chief engineer at Semi Tool, a maker of semiconductor processing equipment in Kalispell, Mont., says his company used a teach pendant for six or seven years, until the supplier stopped making them. Rather than seek out another teaching pendant, Jones adapted a handheld computer (See Figure 2 below) from Xycom, and programmed it to act as the teaching pendant. "We use it in maintenance mode to teach the robots used in our semiconductor processing equipment," says Jones.

Similarly, Wemo Automation, a robot builder in Bor, Sweden, uses handhelds as more than a teach pendant. Wemo uses handheld mobile panels from B&R Industrial Automation to perform everything from setup to maintenance. "With B&R's software, only one tool is needed to program and service all components of the robot system," says Bengt Stahl, Wemo's co-founder. "Further, the same software is used for all types of robot control."

Solution Seeking a Problem?

We conducted a small survey of CONTROL DESIGN's readers, asking them if they use handheld technologies with the machines they build. Not surprisingly, 89% said "no" (64 of 72 responses). When asked why not, slightly less than half of respondents said they didn't consider using handhelds because they saw no customer demand.

Bob Horrell, project manager at Strasbaugh, San Luis Obispo, Calif, a manufacturer of precision equipment for the optics industry, provides a good example of this trend. "Communication with the tools we build — CMP, silicon polishers, surface grinders and edge grinders—is done through recipe entry at the tool or is downloaded from a host," he says. "Handhelds may be desirable at a future time, but there have been no requests up to now."

Steven Connell, manager of systems engineering at Glasstech, manufacturer of glass bending and tempering equipment in Perrysburg, Ohio, also sees no need for handhelds. "Our machine is in a fixed location, we already have redundant HMIs in a couple of locations, the setup of the machine is not a one-man job, and you don't have to worry about a handheld being misplaced," he notes. "Handhelds also are small, so not a lot of data can be displayed." On larger machines that have a few hundred parameters, he adds, it can be difficult to find the specific parameter you need.

{pb}

"Most of what we build involves programmable logic controllers and variable frequency drive systems," says Kevin Baker, senior applications engineer at Industrial Motor & Control, Tuscon, Ariz. IMC builds switchgear and power equipment for the mining industry. "The display on most PDAs is far too small and poor in resolution to fill the bill on the systems we build."

More than half of the survey's machine builders said they looked into using handhelds, but decided not to after their investigations showed handhelds don't work with their control system, or because they thought handhelds weren't reliable or rugged enough, or because, once again, they didn't see any customer demand. Some looked into handheld technology quite deeply before deciding not to use it.

Richard LaBorde, project engineer for AgriChem, a manufacturer of equipment for processing powder and bulk solids in Ham Lake, Minn., says his customers' environments are too tough. "Feed mills are notoriously tough on portable devices," he says. "It would have to be a pretty rugged device to survive for long."

Nevetheless, he'd like to use PDAs some day. "Most of the operators for our control systems are mobile in their feed mills. They don't sit at a desk, so the portability would be nice. We're looking at a new platform for one of our old, reliable microprocessor-based control systems. We like the communications options that WiFi and Ethernet allow, but we're a small supplier, and it takes a lot of tooth pulling to get the brass to go out on a technological limb."

Steve Haubrich, senior principal engineer at Baxter Healthcare in Deerfield, Ill., a manufacturer of medical and healthcare equipment, says his customers don't want the technology. "Our customers don't allow wireless networks," he says. "Plus, they're afraid the PDAs will be stolen. We use Windows CE-based HMIs, but we're not using PDAs. As for me, I worry about battery life, which can limit availability."

Similarly, no customer demand and lack of useful tools are the big reasons why John Pullen, senior staff designer at TDS Automation, a builder of custom automation systems in Waverly, Iowa, doesn't use handhelds. "Rockwell Automation recently introduced some useful drive tools, but I'm not aware of any other vendors doing so. I've also seen Rockwell's PocketLogix in the past. That had some potential, but apparently didn't sell well enough for Rockwell to continue support. I recently purchased a PDA for myself, but I see difficulties in trying to use this for continual development in a PLC environment simply due to the input methods." He foresees problems with letter recognition, the small keyboard, and the size of the screen for displaying useful, readable documentation on a RLL rung.

"I build a lot of HMIs with Visual Basic, and I can't compile a program to run on a mobile platform," laments Ralph Kitts, electrical engineer at Day International, a builder of digital printing, textile manufacturing and corrugated paper converting machines in Arden, N.C. "While RSView, which I use a lot, can be used in certain PDA-like devices, cost is a big issue."

Kitts also is wary of the wireless wars currently raging across the automation industry because he went through that tumult with Ethernet. "I waited for several years before deciding on Ethernet as my remote I/O bus," he says. "Further, the whole handheld device market still is in a lot of flux, with cell phones morphing into PDAs, game platforms, and God knows what else. PDAs arguably would be less reliable than our existing hardwired networks. That leaves PDAs looking like a luxury, not a solution to anything."

- A machine controller based on a PLC or embedded computer that has either wireless capability or an Ethernet port. A PDA connects to a machine's controller via a wireless access point (WAP), BlueTooth, or even infrared. If the PLC doesn't have wireless, but it has Ethernet, then you simply plug a WAP device into the Ethernet port. A serial converter to BlueTooth is another inexpensive option.

- HMI/SCADA software that will run on the PDA. "Today's handheld devices have enough memory and processor speed to run HMI/SCADA software," says Roland. "All you need is a software package that can run in a PDA environment." Such HMI/SCADA software is available from a host of vendors, although not all software will run on all handheld hardware.

- The ability to configure the HMI/SCADA software to the machine controller's I/O network. Configuring a PDA is the same as configuring a PC. "All HMI/SCADA software is capable of being configured to any well-known PLC or controller," says Roland. "Most people are not aware of the powerful tools available for PDAs." Today, it's not necessary to be a C++ programmer or an expert in Microsoft .Net to create an interface for a PDA. Some tools in the market provide communication drivers for all the standard protocols, and provide the same development interfaces for PC applications.

What's more, the same PDA could be used to monitor and control an Allen-Bradley PLC-based conveyor, an Omron-based welding machine, or a Beckhoff-based robot, all running on the same assembly line. "The total number of machines it can handle becomes a problem in scalability," says Roland. "How much data and how many configurations can the PDA's memory accommodate? If a company defines a standard for the PDA graphical interface, all the machines can be easily accommodated, and the user only needs to select which one he wants to connect to."

Neil Frihart, senior instrumentation and controls engineer at Callidus Technologies, a builder of combustion products in Tulsa, Okla., says he won't use handhelds because of "limited interface capabilities with PLCs, and handhelds are not Div. 2 rated, which is important 90% of the time on our equipment." Frihart looked at handheld products from SMAR and Honeywell, but was not convinced. "The handheld computer seems like it certainly should have a future in the controls industry, but it hasn't arrived yet."

Machine builders like LaBorde, Haubrich, Pullen, Kitts and Frihart looked into PDAs for an obvious reason; as Frihart says, it certainly seems that PDAs should be good for something.

On the bright side, Jeff Hadley, engineering manager at Hadley Design, a custom machine builder in Edmond, Okla., says connection and communication issues are stopping him right now, but he also sees a future for handhelds. "A PDA appears to require a significant amount of additional programming to implement," he says. "I believe that, in the very near future, the cost and ease of implementing this type of connection as an HMI or service will allow more widespread use."

About Those Objections…

To explore and respond to some of the objections noted by our reluctant machine builders above, we can offer this information:

- Industrial-grade handhelds are available. Intermec, for example, offers an intrinsically safe handheld, which provides protection in areas containing hazardous gas and vapors, and withstands a 5-ft. drop onto concrete. Industrial covers are also available for most PDAs. For example, iPAQs from HP have an option for "rugged cases," that make them suitable for industrial applications.

- No special programming is needed to make a handheld work with a machine (see the "How Handhelds Work" sidebar). A conventional diskless HMI/SCADA software package loads into a PDA, the same way it loads into a PC.

- PDAs work with PLCs and just about any other machine controller. The PDA just needs to be configured to the controller's network, but the HMI/SCADA software does that for you.

Ernie Roland, president of Indusoft, says a PDA will not necessarily replace SCADA systems or the panel PCs installed at machines. Instead, he says, it will be a complementary tool, which can be used for maintenance monitoring, alarms, accessing equipment information, making corrective actions from databases, and other operator or technician functions. "If the PDA can read data directly from the PLC, it's possible to verify alarms, read data, and diagnose problems with one PDA," he says. "One example is a machine with a system that sends notifications to PDAs. Once the responsible people are notified, they can use the PDA to see the current status, and apply corrective actions that the PDA can read from a relational database."

Greg Mears, product manager at Rockwell Automation agrees. "Our drives can generate e-mails on alarm, fault, and return-to-normal conditions, which can be sent to a PDA or smart phone," he explains. "The user will see fault information. They can also click on a link to launch a web browser that automatically is connected to the drive's web page."

The biggest problem with handhelds is the lack of customer demand. "Many customers are evaluating the options for wireless devices for improvements in productivity and information availability," says Ann Ke, tablet and panel PC marketing manager at Wonderware. "I suspect that demand will increase as they get the wireless infrastructure built into the plant, and resolve security issues around this.

Customers with many field technicians already have implemented wireless systems for remote information access. As for the plant, end users are evaluating wireless devices. However, the debate is whether to get the more expensive tablet or the lower cost PDAs. In this case, it depends on what type of information is required to be displayed and used."

Consequently, customer demand may change shortly. "Our PDA software has a major ‘wow effect' at tradeshows and events," says Mears. "It's the biggest attention grabber I've seen for drive software in seven years. While it's generated a lot of excitement, so far it has yet to generate a lot of implementation." If you wander around any tradeshow these days, vendors everywhere are hawking the benefits of handhelds.

Soon, end users should begin to recognize the benefits and advantages of using handhelds, and they'll start looking for the capability in your machine's controls. Maybe you should be the one to generate a big "wow" effect at your next tradeshow exhibit.

In fact, when's the last time you changed channels, switched DVDs, or told your TV to play a video tape by using manual controls? The same might happen with machine controls: handhelds will become the norm, and conventional HMIs and manual machine adjustments become obsolete.

Leaders relevant to this article: