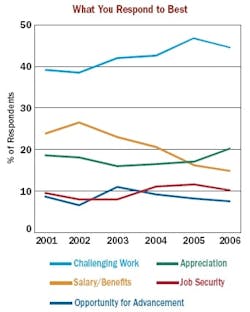

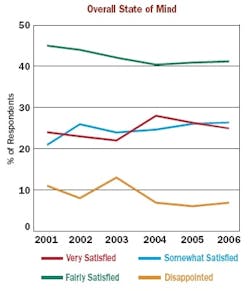

The survey also shows that, although hands-on-experience is waning, concerns about job security are declining and the overall level of job satisfaction is improving. In fact, results show the general state of mind of industry professionals to be at a level not reached since the start of the new millennium.

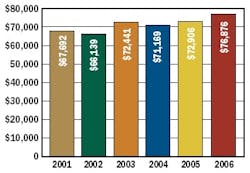

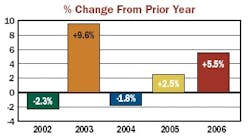

According to the survey, average earnings for responding machine control engineers in all sectors of the industry are more than 15% higher today than they were before the economic slowdown that occurred in the manufacturing sector after 9/11. These findings come on the heels of employment figures released last quarter by the U.S. Department of Labor that showed unemployment in the manufacturing sectors to be at 4.6%, the lowest level in five years.

SALARIES CONTINUE TO ESCALATEMost of our respondents (66%) report being satisfied with the direction in which the industry is going, as well, and despite ongoing concerns about manufacturing and engineering services moving offshore, most respondents (54%) report feeling secure with their jobs and their companies. More than half received bonuses last year, contributing to the rise in pay.

Survey Highlights

Consistent salary increases during the past two years and a healthy optimism about where the future of manufacturing is headed are the high points of Control Design’s 2006 Salary and State-of-Mind Survey. An assessment of this year’s results shows the industry to be in a growth period again, with earnings for machine control engineers reaching new levels, but varying by specialty, age, experience and occupation.

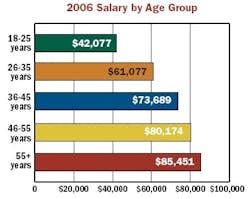

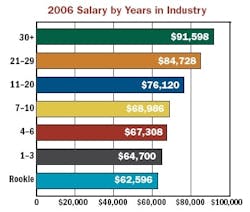

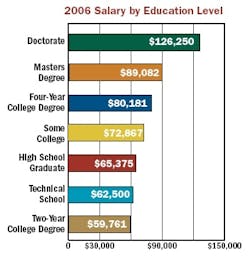

Experience and education seem to count the most when it comes to overall earnings. The largest reported wage gains were experienced by the 55 and older group (8.5%), bringing the average annual salary for that group to $85,451. Those between the ages of 46-55 reported the next largest gains (4.5%) to nearly $80,000 a year. If you’ve been around the industry for more than 10 years, your average salary is up 3.5% this year to nearly $74,000. Those entering the field, however, reported a decline in annual compensation (more than 10%), as did engineers with less than 10 years experience.

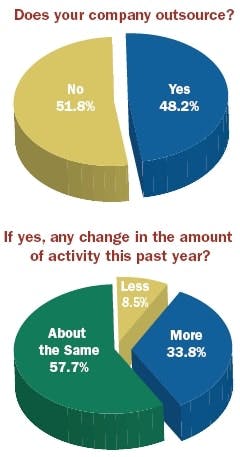

Still, there are worries among many respondents that outsourcing is responsible for a reduction in career opportunities. However, if you’re only catching the bad news, then you’re missing some of the good. The fact is that the industry can’t find enough machine control systems designers and integrators to hire who are experienced with the latest automation trends and technologies, such as lasers, micro-machining and nanotechnology used in machine building.

With the job market and economy on the rise again, many companies are hiring, and offering raises and promotions. More than 46% of respondents said their companies hired this year, up slightly from last year’s total. Layoffs were down, too, by nearly 25% from 2005, while hiring freezes also declined.

Experience Gets the Money

The largest increases in earnings over last year were reported by controls engineers who have worked in the industry more than 20 years. This growing sector represents 33% of the total respondents to the survey.

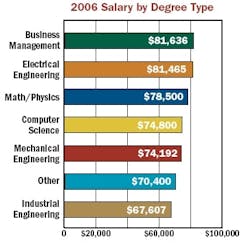

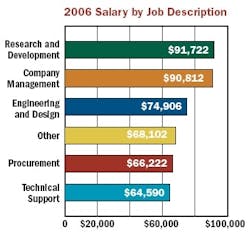

It seems the most lucrative positions in the machine controls sector are those involved with research and development. Average annual salaries for those fitting that job description saw their pay increase to $91,722, followed closely behind by company management jobs that average $90,812.

Increases also were reported this year by a majority of those with only some college education. However, the overall majority of engineers working in the industry hold four-year degrees, mostly in the fields of electrical or mechanical engineering.

Besides a degree in electrical or mechanical engineering, the typical machne control professional has approximately 18 years experience in machine control and automation. He (95%) or she works about 45 hours a week, has worked for three different companies during their career, and has been with their present employer for the past 12 years.

Most of the respondents to this year’s survey (64%) work at companies with more than 100 employees, and nearly half of all people answering the survey work for companies with more than 200 employees.

The clear majority of respondents (58%) report engineering and design to be the category that best describes their job, with the remainder divided between categories that include machine assembly, research and development, company management, procurement and tech support.

Those working in machine controls engineering and design also reported salaries closest to the average of all engineers working in the machine builder industry, with average annual incomes up 4.2% over last year to $74,906. The largest group of survey respondents (23%) works in engineering and system integration services, followed by metalworking machinery and machine tools industries.

What Irks You?

Some respondents say it’s higher education and rookies fresh out of school. One respondent says, “Students today seem to be getting theory, but no application of theory, and no understanding of how theory pertains to real automation situations.” Another adds, “Just because someone can program a PLC doesn’t mean they can design a control system. Today’s controls engineers lack the knowledge of those before them.”

State-of-Mind Interviews

Scott Bivens

"Not Just Another Tool in the Toolbox"

Scott Bivens is electrical engineering manager at Packaging Technologies in Davenport, Iowa. Bivens says Packaging Technologies resumed hiring this year, and, in addition to a giving out bonuses, the company awarded raises, promotions, and is offering more overtime.

Bivens says what he likes most about the current state of the industry is that “new opportunities to be creative occur almost every day in controls design engineering. Every day is different from the last.” However, the pressure to work under time constraints can be frustrating, which often makes him feel like “just another tool in the toolbox, as if a controls engineer can be replaced by just anyone off the street,” he says.

“I enjoy working in this industry very much,” he adds, “ but what is fun to me might not be to someone else. You have to enjoy logic problems and the suspense that comes from working toward a solution that you know exists but that you do not yet possess.”

Mike Bagley

"Making the Process Come Alive"

Mike Bagley is director of engineering for ICS Inex Inspection Systems in Clearwater, Fla. Bagley manages fast-paced machine design and development groups, coordinating hardware and software systems and building prototypes.

Bagley says ICS gave out raises and promotions last year and currently is not outsourcing any of its automation and engineering services. What still makes his job interesting to him is his love for designing and inventing machines, and gaining patents for his work. Least satisfying to him are the last-minute panic specification changes that constantly occur at his job.

The best part of being a control design engineer, according to Bagley, is inventing and building a new machine that nobody else has built. “There is great satisfaction in seeing a full system being manufactured on the production floor that a few months ago was just an idea in my head and a sketch on a white board,” he says. “I’m doing something I really enjoy doing. I love Mondays!”

Bernie Kosciuk

"Machine Building From the Ground Up"

Bernard Kosciuk is engineering manager for Pistorius Machine Co. in Hauppauge, N.Y. Pistorius’ manufacturing facilities include a fully equipped machine shop with CNC machining centers and fully computerized engineering facilities using CAD technology.

“As a controls systems engineer, it’s very satisfying to design and create a working machine/system from the ground up,” he says. “I enjoy being in a field that allows me to use and be exposed to cutting-edge technologies.”

According to Kosciuk, the decision to become a control systems engineer really wasn’t a conscious choice, rather more of an evolution.

“Control engineering is the most interesting and fun part of machine design,” he says, “because there is a more rapid evolution of advanced control components compared to mechanical and electrical components. It typically is the last phase of the overall machine design, so there’s an element of satisfaction when all the systems are integrated and the project is completed.”

Dr. Charles Tolle

"Mentoring the Next Generation"

Charles Tolle holds a Ph.D. and works in research and development at Idaho National Laboratory in Idaho Falls. His research focuses on control systems for biological, welding, and high temperature processes, as well as complex/chaotic system modeling and signal motivation. He has authored numerous papers on applications for motion control, target detection, guidance, vision, fractals, signal motivation, and chaos theory.

Tolle also is mentor to the Idaho Falls First Robotics team, an organization of students working on everything from differential equation reconstruction based on attractor embedding space, to real-time robotic integration and simulation, and advanced graphical user interfaces.

“We use controls everywhere,” he says. “Our field is one that can lead you to learn and explore every science or discipline in existence. Control design engineers have the lucky challenge to discover how systems behave in fundamental ways, so that we can influence them into behaving as we desire.”

For Tolle, working, teaching and learning controls isn’t just fun, it’s his life. “It’s great to make machines and processes come alive!” he exclaims.

Joe Kolo

"Education vs. Experience"

Joseph Kolo is a manufacturing engineer at Crary Industries, a builder of metalworking machinery headquartered in West Fargo, N.D. His experience includes metals fabrication and the design and building of packaging machinery specifically for industrial automation applications. He has worked as a mechanical designer, controls designer, assembly technician, and electrical and pneumatics technician during his career.

“I feel my higher education alone did not, and would not, adequately prepare me for the level of automation I’m currently involved in,” Kolo believes. “My experience is from education, hobbies, pursuits and experience.”

“Industrial engineering was instrumental in giving me the skills to identify production needs related to automation and controls,” he says. “My work in an automation lab at the University of Minnesota–Duluth allowed me to implement the automation of processes with robotic manipulators, and to learn more about motion control and the electrical and mechanical aspects of work cells.”

Tommy Pool

"Keeping Up with Technology"

Tommy Pool is an electrical engineering manager at packaging machine builder Kliklok-Woodman in Decatur, Ga., who says the control design field stays interesting “because the technology is constantly changing and the methods of solving a recurring problem always are different.” Pool says he reads everything he can about controls engineering and tries to attend as many applicable seminars and training sessions.

“I enjoy automation and working with customers to help them get the best application in their particular circumstance,” says Pool. “I like to have the freedom to learn more as technology changes.”

Pool’s knack for machine building and computers led him in the direction of controls engineering, where he still can do the hands-on work he loves and use his experience to help train others.

“Higher education isn’t teaching enough of the core basics of control,” comments Pool. “Students today seem to be getting theory but no application of the theory, and no understanding of how the theory pertains to real automation situations,” he says. “I found that the time I spent at college gave me basics and taught me how to learn and how to think in terms of real automation situations,” he says. “I actually use more of what I learned than I thought.”

"Experience Comes a Long Way"

Tony Kelly works as a combustion specialist at Industrial Thermal Systems, a builder of combustion and instrumentation process and HVAC systems located in Cincinnati. Kelly is a tech school grad from England who always is a little worried about job security, despite the end of hiring freezes at his company and bonuses being paid last year.

Kelly is living and working in the U.S. on a visa. Although he has nearly 40 years experience, the past five years spent working in machine control and automation has allowed him a variety he enjoys.

“In this field, experience in a range of applications is very valuable,” he says. “From building automated machinery that bakes pizzas, makes automobiles, or melts aluminum, it’s always fun,” he says. “Especially when it works!”

"Integrity for Security"

Mike Dionne is a senior electrical design engineer for Integrity Integration Resources an engineering and system integrator located in Dallas. Dione primarily designs control panels for applications in the food and chemical processing industries, and system integration electrical design on PLC and motor control systems. He’s concerned about job security, despite the fact that his company has been hiring again and offering more overtime. According to Dione, I2R outsourced a portion of its automation and engineering services last year and is reportedly doing more of it this year.

"Still a Thrill"

Joey Watkins is a design engineer at Bellwright Industries in Summerville, S.C. Bellwright specializes in medium-to-high production CNC machining and assembly.

Watkins, a tech school grad who has worked in mechanical engineering and design, machine fabrication, machine design and trouble shooting for nearly 20 years says he’s not too concerned about job security these days. He says his company has been offering more overtime lately and that it doesn’t outsource any of its work.

What makes Watkins happy is that machine control design allows him the flexibility to try different things in order to implement changes. “I still remember the first machine I ever designed,” he boasts. “To see the final product in action for the first time, and to see that product working as designed, is always a thrill.”

"A Life in Control"

Dan Stirpe is a senior electrical engineer at Dauphin Graphic Machines in Elizabethville, Pa. Dauphin designs and builds commercial presses for the printing industries.

Stirpe earned his EE degree from Gannon University in Pennsylvania and has spent more than a decade designing control systems for commercial printing presses. Stirpe says he’s satisfied in his job and challenged by the work he performs at Dauphin. He also indicates he’s less concerned about job security today than he has been in the past. Dauphin experienced layoffs in recent years, but the hiring freezes of 2004-2005 are being lifted.

According to Stirpe, Dauphin outsources some of its automation and engineering services, but less this year than last. He’s currently working on a variety of different types of control systems: from relay logic and hard wired systems, to network-controlled shaftless servo-driven machines.

Stirpe grew up working in the printing machinery industry. After college, he took a field engineering position servicing and commissioning web printing presses. He later worked as a controls engineer designing auxiliary machine controls.

“In some ways, I feel that many of the new people coming into the industry are better trained than I was in practical control and automation skills. I had to learn controls the old fashioned way: trial by fire.” By comparison, Stirpe says he was more than two weeks into his first job when he first heard of a PLC.

Stirpe believes today’s graduates are receiving a good foundation of usable skills, but little practical industry-specific training. Something, he says, is like “putting the steering wheel in the trunk, the brakes in the back seat, and the mirror, pretty bells and whistles directly in the driver's line of sight.”

“In the past, it was important for colleges to teach the basics: lots of theory and math with little practical training,” he says. “Your real-world application of these basics was taught to you by senior engineers. But this hasn't been the case for 20 years.

Stirpe says companies don't keep armies of engineers on staff anymore and throw entry level people into sink or swim situations. “Just because someone can program a PLC doesn’t mean they can design a control system. Today's controls engineers lack the specific industry knowledge of those that came before them. How can someone design an automated system for a machine when they have no knowledge of that industry's procedures, jargon or history?”

Stirpe says he’s seen too many control systems designed to sense to programmers or engineers, not to machine operators. Touch screens that look pretty but make no sense to the machine operator, and controls that should be grouped together but instead are plastered onto three different screens, all contribute to what Stirpe calls “no thought or understanding of the process being controlled.”

But control system design appeals to Stirpe because it is the most interesting field of electrical engineering. “It combines most aspects of electrical engineering and programming with mechanical concepts and links the virtual world to the machine world,” he says.

Most of Stirpe’s controls background was self-taught by debugging and redesigning other people’s controls. He also attended training schools for various PLC and drive control systems. But, for the most part, he says he learned from his own mistakes, and those made by others.

“My work in the industry has given me the advantage of understanding the process and machinery involved,” he says. “Control design is the best of all worlds. It’s not as isolated as other fields of engineering. You have to interface with the other machine designers as well as the machine operators. There’s always something new, or at least a new way of doing things.”

| Methodology |

Earlier this year, we e-mailed invitations to our subscribers and included a link to the survey in several of our e-newsletters. Six-hundred and seventy-seven usable survey responses were returned to us. Results were analyzed and additional interviews were conducted and presented here.

Leaders relevant to this article: