In fact, the Wheel helped the oil industry convert from paperboard to plastic one-quart containers beginning in the 1980s, and it remains a dominant technology among high-output blow-molding systems.

The Wheel comes in a variety of sizes from nine to 24 mold stations, and its manufacturer, Graham Engineering Corp. (GEC) of York, Pa., has made several size iterations over the years. The firm’s rotary blow molders are used at plants where opaque bottles are produced then immediately filled with automotive fluids, household detergents and cleansers and beverages, or are sold empty.

Wheel’s main component spins around a horizontally mounted axis. Up to six extruders feed plastic into a flow-head component to quickly form bottles in any type of thermoplastic, and create complex battle-wall structures with up to seven layers. The process begins with upward extrusion through a plastic parison tube at a precise location in relation to several rotating mold sets. These sets are located around the rotating axis, which closes just above the extrusion flowhead, where the continuous parison exits. This happens at the 9 o’clock position, where the parison is inflated by air pressure then is rotated around for a container discharge at the 6 o’clock position. The wheel’s operation is all-mechanical via opening and closing cams.

PC-Based Control Evolves

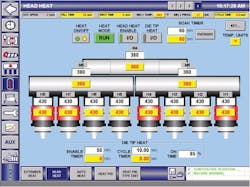

While some machine builders shy away from challenging their users and stick with PLCs as an excessively safe controls specification, Graham reports it long ago incorporated PC-based controls into its rotary blow molders. Wheel’s main control platform has been PC-based for more than five years (See Figure 1 below). However, the price of being an early adopter is that upgrades come at you faster, and Graham was no exception.

Graham Engineering’s Wheel rotary blow molding system experienced growing pains during the first five years it used PC-based control.

“As is the case with many products, there was demand for us to increase bottle production to meet various requirements due to meet expanding product offerings available to the consumer today,” says Dave Fiorani, Graham’s engineering manager. “As the speeds of the extrusion became faster, the need for more precise control of temperatures and parison programming were needed. In 2003, we decided that our existing PC hardware platform wasn’t going to keep up with our machine design migration. We needed to find a successor.”

When the durability and processing power limitation of its previous PC hardware vendor became apparent, Graham’s engineers evaluated industrial PCs from five major vendors using more than 20 critical performance criteria grouped into seven major areas, including:

- Ability to buy commercial off-the-shelf (COTS) components from any PC store to replace failed components, adhering to ATX open standards

- Software to map I/O capable of running on any PC

- Integrated UPS function blocks to handle proper PC shutdown

- Capable of direct communication to the HMI, with no OPC server required

- Ability to provide an operator station with fully integrated pushbuttons

- Highest speed processors currently available on the industrial PC market

- Software updates available for download from the Internet, and upgrades available at no charge after initial license purchase

Flexibility Aids Efficiency

Following a lengthy evaluation, Graham chose Beckhoff Automation PCs with 2.4 GHz Pentium 4 processors running TwinCat software as the main control for its Wheel rotary blow molders. “We write all sequencing/temperature code and HMI code in house at Graham using TwinCat software and Indusoft’s HMI software for the interface,” adds Fiorani. “TwinCat allows us to do sequencing in real time. We write our own algorithms for PC-based control and to create motion and temperature profiles. This task is a lot faster now because we don’t have to rely on other suppliers for motion control cards. Ultimately, we’re a lot more seamless, and we can reduce the cost of our system because we don’t need discrete motion control on other products we’ve had to buy separately.”

Justin Kilgore, Graham’s senior electrical engineer, adds that “Most of our machines could be controlled using PLCs, but for a few specialized machine types, we need NC functionality. As a result, we use TwinCat NC across the board, so we’ll be able to use a standard software package.” GEC uses many of the languages provided in its IEC 61131-3-compliant programming environment, including ladder, function blocks, function block diagrams, structured text, and continuous function chart. (See Figure 2 below).

FIGURE 2: SPEAKING CLEARLYIn addition, remote I/O replaced costly PCI I/O cards supplied by the prior PC vendor. Graham now uses special-function I/O terminals for Wheel’s e-stop functions and temperature measurement. Kilgore also opted to use a watchdog I/O terminal. “That eliminated possible errors from the machine and heater controls,” he adds. “You can set timing based on your application, but we wanted a PC pulse every 100 ms. Now, if the system detects an error in the control system, the e-stop automatically is engaged on the machine.” It also monitors a bit that’s toggled by the controller during each cycle. If the toggle signal fails, the controller switches off two relays that are integrated in the emergency stop circuit to prevent damage to the machine.

A thermocouple module is used over Profibus to monitor 32 thermocouple zones in one Pos-E-Kon enclosure. Variable-frequency AC drives also are networked via Profibus. Meanwhile, a strain gauge isolator is used to bring in various pressure transducers. Previously, GEC needed added hardware to perform the same function.

“In addition, I/O addressing is highly automated and very simple,” says Kilgore. “With our previous PC software, an engineer had to address all of the I/O at the bit level, often with hard-coded I/O points and following printed guide sheets. This process was time-consuming. We now save eight to 16 hours of I/O addressing time on each machine.”

Testing Made Easier, Too

To test and apply the Wheel’s new controls and machine components, Graham uses its own Lab Wheel rotary blow molder. This device can test several different bottle types, mold sets, and head configurations, but this means it needs extremely high flexibility.

Before testing Wheel’s new hardware, Lab Wheel was fitted with a PLC platform from a wholesale discount PLC vendor. “With Lab Wheel’s PLC system, we lacked changeover flexibility, which became a source of headaches when testing newly designed machine components,” says Rolf Weingardt, Graham’s R&D manager. “Since then, we’ve had Beckhoff’s PC running on the Lab Wheel for more than a year and a half, and we’ve had none of the flexibility concerns we experienced in the past.”

In addition, by using this PC in a separate control cabinet, Graham replaced the Lab Wheel PLCs rack-for-rack with Bus Terminal I/O. “We didn’t have to do any internal wiring changes on the Lab Wheel and were able to use all our existing wires,” adds Paul Klinedinst, Graham’s senior development engineer. “We saved more than 200 hours of I/O wiring time because of this I/O flexibility. The process also meant we had minimal downtime to complete the platform conversion.”

Pampering Parisons

The Wheel’s updated PC-based controls have now moved to its parison programmers, which must precisely control the wall thickness at various sections of each bottle. These programmers require high-speed, analog I/O to quickly control the motion of the Wheel’s molding process to within a few thousandths of an inch. As a result, Graham selected EtherCat Ethernet I/O to network the parison programmers.

Graham reports that implementing EtherCat allowed it to eliminate the parison programmers’ previous controller, which was a custom, high-speed I/O circuit board. “The fastest we’d been able to close the loop on the parison programmers used on our previous machines was 1 ms,” says Klinedinst. “Now, we can close the loop on the Lab Wheel as fast as 150 µs. We’re presently getting better performance with more control over the parison programmer than with any of our previous systems. The bottles-per-minute rate on our machines is basically fixed due to the cooling stage of the bottles. However, we’re capable of making higher quality bottles today because we’ve adopted EtherCat.”

In addition, Graham was able to cut additional cost by using the most cost-effective, single-channel, standard Ethernet cards on the PC wherever possible, and using Profibus and Lightbus cards where non-Ethernet fieldbuses are still required.

Leaders relevant to this article: