By Jim Montague, executive editor

Many folks put one toe in the water first. Others jump in with both feet.

So, while most process control users gradually test wireless for limited monitoring in non-critical corners of their plants, a few brave engineers blanket their facilities with multiple wireless protocols, and find more and more places and applications to use wireless and gain its advantages.

We joke that weve basically turned our site into a giant Wi-Fi hotspot, says Dave Runkel, production manager at Texas-based Lost Pines Power Park, which includes a 42-year-old natural gas plant and is part of the Lower Colorado River Authority. Located about 30 miles from Austin, the park began operating as a combined-cycle, cogeneration power plant in 2001. In a combined cycle, electricity is produced from several different thermodynamic cycles, with a heating system ultimately used as a condenser of the plants bottoming cycle. For example, the exhaust from a gas turbine might be used to power a steam turbine, the condensate from which provides heat. Lost Pines Power Park now is a 545-MW facility thats reportedly 30-40% more efficient than traditional gas-fired plants (Figure 1).

Figure 1: Lost Pines and Sim Gideon

Lost Pines Power Park began operating as one of the nations first combined-cycle, cogeneration power plants in 2001, and now is a 545-MW facility thats reportedly 30-40% more efficient than traditional gas-fired plants.

Photograph courtesy of LRCA

Many of Sim Gideons systems were reaching the end of their useful lives and needed to be replaced anyway, says Runkel.

Management began with an RFP for a hard-wired PA system, but that caused instant sticker shock, so we began to ask ourselves if wireless might resolve some of the communications differences between the two facilities. So, the PA was our first system to go wireless. Now, each day, were finding new ways to incorporate wireless into our infrastructure.

Runkel says it was during Lost Pines annual strategic alliance meeting that representatives from Invensys proposed implementing a wireless umbrella at the plant. Lost Pines and Invensys jointly conducted a wireless assessment to determine coverage and equipment placement and then implemented a smorgasbord of wireless solutions to tie the two plant sites together. These solutions included:

- Building a 360° WiMax backhaul that created a wireless umbrella over the plant (Figure 2);

- Installing 52 Wi-Fi access points throughout the plant for local area network access;

- Establishing a common-infrastructure enabled voice over Internet protocol (VoIP) to support a wireless Vocera push-to-talk application;

- Installing wireless speakers throughout the facility (Figure 3); and

- Integrating the overall system with the staffs PBX and personal cell phones for enhanced connectivity.

Figure 2: Under the Umbrella

A 360˚ WiMax backhaul installed at a high point in the middle of the power park creates wireless umbrella over the two-plant site.

Photograph courtesy of LRCA

Lost Pines new wireless infrastructure uses Invensys-partner Apprions Ionosphere network platform and Ionizer devices. The Ion platform manages the controller and distributed component appliances, as well as three high-speed and three low-speed radios at Lost Pines, says Steve Lambright, president and CEO at Apprion. The platform scans and acquires all the wireless devices at the site and brings them under its management This allows the application to be integrated and visualized and gives Lost Pines a geographical MySpace for its entire plant, with all of its devices in one view. Users can click on a listed device and display its management console or click up- and downstream through the system. As a result, claims Lambright, wireless can provide immediate, measurable ROI, an extensible framework and infrastructure, lower entry costs, more vendor choices, predictable ownership costs, and improved physical security and safety.

Runkel adds that Lost Pines three main wireless technologies provided a way to economically solve the two sites communications differences and provided a foundation for continued return on investment by future-proofing the facility for down-the-road wireless applications. This also created a cost-effective means to bring lower-priority equipment controls, indications and alarming functionality to a central control for monitoring, says Runkel. Also, wireless enabled connection of remote sites via long-distance WiMax technology. For example, were wirelessly controlling our river pumping station 5 miles away, where were monitoring flow and currents, and even turning pumps on and off. Were also in the engineering design phase to include wireless at a remote/unmanned peaker plant site.

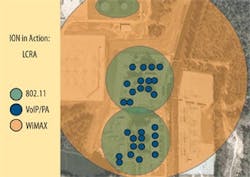

Figure 3: In the Right Circles

A birds-eye view of Lost Pines shows where WiMax, Wi-Fi (IEEE 802.11), and VoIP coverage radiuses are located at the two sites.

Photograph courtesy of LRCA

Some other wireless applications presently in development at Lost Pines include more use of WiMax longshot technology, extension of push-to-talk communications with a parent site, video surveillance of plant for security and visual monitoring, possible equipment health monitoring, FW heater level control and alarming, tank farm fuel-oil level indications, high-temperature furnace video monitoring, burner performance, fireball monitoring, burner tilt performance, miscellaneous alarming functions, sewage lift stations, and anhydrous ammonia leak detection.

The main lessons we learned are to get IT involved early and dont fight them; form a project team early; dont let wireless be implemented in an ad hoc fashion; think enterprise-wide because wireless isnt just for control measurements; and understand theres no one technology that will address all needs, says Runkel. Opportunities for wireless applications are limited only by our imagination.

Wireless 101

WiMAX stands for Worldwide Interoperability for Microwave Access, and was named by the WiMAX Forum. Its an IEEE 802.16 standards-based technology that enables delivery of last-mile wireless broadband access as an alternative to cable and DSL. WiMAX will provide fixed, nomadic, portable, and, eventually, mobile wireless broadband connectivity without needing direct, line-of-sight to a base station. In a typical cell radius deployment of 3 to 10 km, forum-certified systems can be expected to deliver capacity of up to 40 Mbps per channel, for fixed and portable access applications.

Wi-Fi is the name given to IEEE standard 802.11b for wireless local area networks (LANs) operating in the 2.4 GHz spectrum with a bandwidth of 11 Mbps. Wi-Fi is administered by the Wi-Fi Alliance, which reports that Wi-Fi and WiMAX will coexist and become increasingly complementary technologies for their respective applications. Wi-Fi technology was designed and optimized for LANs, while WiMAX was designed and optimized for Metropolitan Area Networks (MANs). WiMAX typically isnt thought of as a replacement for Wi-Fi. Instead, the alliance adds that WiMAX complements Wi-Fi by extending its reach and providing a Wi-Fi-like user experience on a larger geographical scale.

VoIP or Voice over Internet Protocol (IP)also known as IP Telephony, Internet telephony, broadband telephony, broadband phone, and voice over broadbandis the routing of voice conversations over the Internet or through any other IP-based network. Companies providing VoIP service commonly are referred to as providers, and the protocols used to carry voice signals over the IP network are referred to as Voice over IP or VoIP protocols.

Leaders relevant to this article: