By Barry Stringer, president, Solvere

MikroPul manufactures dust control and product recovery equipment for industrial applications worldwide. Located in Charlotte, N.C., the companys products range from small unit collectors to complete engineered baghouse systems in industries including cement and rock products, chemical processing, food and pharmaceutical, mining and minerals, primary and secondary metals and power generation.

Among the companys major products are pulse-jet baghouse filtering systems (Figure 1) that contain a vertical array of tubular cloth or pleated filters in a housing. Dust-laden air is fed into the space surrounding the filter elements and passes through them to the exhaust. A pulse-jet system, originally invented by MikroPul in 1956, keeps the filters from clogging with accumulated dust, says Richard Kapcha, control specialist, MikroPul. An array of compressed air manifolds and venturis periodically pulses pressurized air into the bags to flex them, causing the accumulated dust cake to break up and fall into a hopper. A major advantage of the pulse-jet baghouse over other filter types is it can operate continuously, without being periodically shut down for cleaning.

HOUSE OF BAGS

This dust collection baghouse for cement kiln dust control contains a vertical array of tubular cloth or pleated filters in a housing.

Source: Siemens Energy & Automation

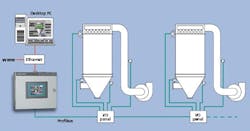

MikroPul also makes and sells filter system controllers. For many years our systems consisted of high-end and low-end units based on a proprietary greenboard controller, reports Kapcha. Our new, more-advanced pulse-jet cleaning system, PulsePro EC baghouse control and monitoring system, replaced the old, high-end product (Figure 2), is built around PLCs and also provides leak detection, baghouse monitoring/diagnostics and trending.

Intelligent or conventional timer cleaning modes are available. For intelligent cleaning, says Kapcha, the system monitors the differential pressure across the filter bags to determine pulse frequency. A graphical, password protected touchscreen interface makes monitoring, navigation and input simple and intuitive. A single PulsePro EC panel can monitor multiple bag houses via network communications, providing considerable savings compared to dedicated controls. A built-in Web server allows the unit to be accessed via Ethernet to remotely monitor baghouse status and change set points securely from any computer on the Internet.

OUT WITH THE OLD

The new PulsePro EC provides control and monitoring for multiple baghouses and optionally connects with PCs via Ethernet and Internet.

Source: Siemens Energy & Automation

Time for a Technology Change

At the low end, however, it was difficult for MikroPul to justify the cost of replacing its long-used proprietary greenboard controls. These basically were simple time-delay relays. For adjustments the system used rotary potentiometers that had no digital units scale and were nonlinear and unreliable.

The greenboard controls had no operator display and no way to tell what operating change an adjustment actually would make, says Kapcha. The technology was advanced when it was first introduced, but now is decades old. In addition, the boards were made by a small, local company with limited resources and no worldwide support. The boards themselves were difficult to customize or modify and had limited capabilities for future system needs such as diagnostics, alarming or differential pressure inputs. Changing the number of outputs, he adds, required the customer to unsolder and resolder connections on the circuit boardhardly a convenient method.

It was clear to MikroPul that the two solutions created a hole in our product line, says Kapcha. Customers could buy a high-end system or a low-end timer board, but there was nothing in between. The midrange was left vacant. It was past time for a new controller design.

All in the Family

MikroPul is a part of Beacon Industrial Filtration, and some of Beacons companies work with system integrator Solvere, based in Belmont, N.C. Word of mouth brought MikroPul to Solvere to discuss its new controls requirements.

We wanted a modern design with better performance and reliability that would make it easy for customers and service technicians to adjust timers accurately for air solenoid durations, states Kapcha. The design needed to be based on a general-purpose, nonproprietary controller with digital DC inputs, relay outputs, integrated timers and counter functions, accessible keypad and a display for easy timer/counter setpoint changes.

The controller, adds Kapcha, also would have to be rugged, be installable in harsh environments and include worldwide agency approvals, such as UL, cUL and C1D2, to meet the requirements of several markets. It also would have to be scalable to meet future equipment design needs with minimal additional cost and engineering time, while reducing the number of parts in each equipment design. At the same time it would have to be cost-competitive with the simplest timer board.

Choosing a Programmable Relay

Solvere has experience using several programmable relay brands but for the MikroPul systems Siemens Energy & Automations LOGO! programmable relay (Figure 3) was the best fit for the stated requirements. The Siemens products came with worldwide support and availability, the needed agency approvals for several markets/industries, the reliability wed experienced with Siemens products, password options for multiple memory modules (write-protect/non-write protect with/without password features) and a PROM burner accessory for duplicating memory modules.

This relay essentially is a simplified PLC and replaces individual components such as rotary timers, cube relays, thumb wheel adjustable counters and contactor relays, says Paul Ruland of Siemens product marketing, Automation and Motion Division. It has eight basic logic functions and 28 special functions, and its I/O can be increased using expansion modules. Solvere was able to quickly provide a completely configured and programmed prototype system to be tested in the MikroPul lab.

Another advantage of the programmable relay is that products built around it can improve along with its technology curve. If Siemens comes out with upgraded LOGO! products, MikroPuls product will be able to upgrade as well without a significant investment in time by either MikroPul or Solvere, says Ruland.

SIMPLIFIED PLC

The LOGO! programmable relay replaces individual components such as rotary timers, cube relays, thumb wheel adjustable counters and contactor relays when installed in a baghouse controller.

Source: Siemens Energy & Automation

The MikroPulse 100P Clean-On-Demand controller (Figure 4) uses a 010 in. differential pressure transmitter that monitors the pressure drop across the filter bags and triggers cleaning pulses when the differential pressure reaches a user-selected setpoint. Setpoints are set digitally using the built-in keypad and display on the programmable relay instead of potentiometers, explains Kapcha. In most cases, this uses considerably less compressed air than timed pulses and lengthens bag life due to fewer pulses.

As the cost of compressed air has increased, many companies have instituted formal cost-saving programs. While a standard timer board might clean every 5 sec, for example, measuring pressure drop might allow cleaning every 30 sec, making for significant compressed air savings.

Other clean-on-demand timers wait until bag differential pressure is high to begin pulse cleaning and then over-clean to bring it to a lower level. The MikroPulse 100P senses even small changes in differential pressure and responds by providing the precise amount of cleaning needed to control it. There are no wide swings in differential pressure and air flow, less compressed air used, longer bag life and reduced fan power consumption.

The new controller uses the programmable relays LCD and keypad for easy timer setpoint adjustments that are more accurate and reliable than the potentiometer timer adjustment on the greenboard, says Kapcha. The unit is more cost-effective for the smaller and simpler MikroPul equipment than a traditional PLC and operator interface combination. Configurable LCD display messages provide intuitive diagnostics messages for easy system troubleshooting and maintenance, saving significant maintenance time and cost.

Both the MikroPulse 100T and 100P are initially programmed with all required functions using the programmable relays software on a connected PC. The relay program can later be changed using the software or, for simple changes, can be reprogrammed directly from the built-in LCD and keypad. We benefit from both the built-in programming capability for quick field startup changes and reduced service costs from password-protected programs that allow us to send a customer a plug-in memory cartridge with program updates, says Kapcha.

PRESSURE DROP

The MikroPulse 100P Clean-On-Demand controller triggers cleaning pulses when the pressure drop across the filter bags reaches a user-selected setpoint.

Source: Siemens Energy & Automation

The major advantages of the new design for MikroPul include a great reduction in the number of controller parts previously stocked and cataloged, saving inventory costs and lowered operational costs. It also reduced engineering and installation time for existing systems, reduced time to market on any new system designs and increased the companys market reach, competitive advantage and technology image in the industry, adds Kapcha.

Theres a side benefit for MikroPul as well, says Kapcha. The new customizable and programmable controls have enabled our company to expand its portfolio of products to now include a new line of baghouse control systems separate from its filtration equipment, he states. And this has, perhaps unexpectedly, opened the door for customers to ask us for more integration and for quotes on other jobs, even extending to motor controls and variable frequency drives that previously they were not given opportunities to bid.

Barry Stringer is president of system integration firm Solvere, Belmont, N.C.. Learn more about the company at solvere.net.

Leaders relevant to this article: