The stakes are high. Big manufacturing companies want to build mutually beneficial, long-lasting relationships with their key suppliers. Manufacturers also routinely expect better leadtimes, faster commissioning and higher performance from their machine system partners. They expect machine motion to be flawless from Day One. If they don't get what they expect, that business relationship will not last very long.

SEE ALSO: Simulation: Prescription for Success

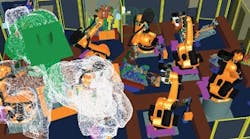

AKE Robotics understands these facts well. The company is a subsidiary of the German enterprise AKE-Systemtechnik. The parent company designs and builds everything from transport systems to robotic manufacturing cells. AKE Robotics, located in Bielsko-Biala, Poland, configures and programs all types of industrial robots for applications in manufacturing, assembly and logistics. By incorporating the most current technology in industrial robotics, AKE Robotics meets the demands of a list of exacting customers that includes Audi, Mercedes, Seat, Volkswagen and Volvo Ghent.

Precision Absolutely Required

Supplying robots to the global market requires the highest quality standards. The configuration of crucial production environments has a decisive influence on the high level of responsibility for each realization. In many situations, AKE Robotics' work is constrained by time and space limitations, but the company still must deliver reliable, essentially flawless robot operations. Inaccurate installations result in costly production downtimes and require considerable expenditures to correct. Also, when there are errors, repair work must be done at the customer's site, which significantly reduces the profitability of that project.

Software Compatibility Is Key

To improve quality and minimize risks, AKE Robotics decided to implement a robot programming and simulation solution. One of the essential features the company searched for in this type of software was compatibility with leading computer-aided design (CAD) systems. In addition to making its own designers' work easier (if customers' CAD data could be imported), compatibility with other systems also would make it easier for the company to grow into new markets.

"We want to import almost all CAD data available on the market, including catpart, stl, nx and ugs," says Bartłomiej Siuda, managing director at AKE Robotics. "Most linebuilders and automakers use Catia for 3D prototyping, and these models and elements are most helpful to have."

Siuda says that before AKE made its software change, there was only online programming and on-site finishing. "There was no possibility to test if everything was OK, until it was made in metal and mounted," Siuda explains. "The engineer could not test if, for example, all spots or robot positions are allowed and possible to reach."

AKE worked with the biggest automakers before the move to Robcad, but at a lower level. "The car-building market is very specialized and standardized," Siuda says. "Mostly every car company standardizes on the software it will use. Right now, only Robcad and Delmia V5 count in this market. If you want to do simulation and offline programming (OLP), you have to use Robcad and/or Process Simulate (PS), a new Siemens product."

Siuda points out that all of the company's designers already had used Robcad at previous jobs, so the software was implemented very quickly. "If you are not experienced with 3D simulation and CAD systems, you need about one and a half or two years to become a good and efficient programmer," he says. "At AKE, we train students while they are in their final year of school. With such preparation, we are able to have good specialists in 3–6 months."

Numbers Reflect Success

The use of Robcad improved employee productivity dramatically at AKE Robotics. The designers no longer waste time redesigning elements of a robot system that already exists. "The designers and constructors see their possible mistakes during the simulation process and not when it's actually fabricated and assembled," Siuda states.

That means they can create systems that don't require changes as they are installed. In the past, when assembly and process-related errors occurred, employees would have to spend long periods at customer sites across Europe. Not only did this reduce the profitability of a project, it prevented those employees from taking on new tasks.

"Robcad lets robot programming be done offline and not at the customer's site," Siuda says. "The software's simulation functionality literally reduces errors found as the robots are being installed. Let's say you have to start up a line with 25 robots. You program with parts models from the client. When everything is nearly finished and you have two weeks until deadline, the customer then tells you that you were working with the wrong CAD data. The project has been running for 3–4 months, so with only two weeks working online, it is impossible to keep deadline unless you had 3D OLP software like PS and Robcad."

SEE ALSO: Market Intelligence Report: Design & Simulation Software CIA Virtual Brigade Briefing

Working at the customer's facility is very costly. "Robcad lets us work remotely in the preliminary stages of a project, and also lets us detect and eliminate collisions early on," Siuda says. "This has reduced the project travel costs by 25%, saving 120,000 zlotys (about $37,000) per year." Overall, he estimates that the improved productivity gains from using Robcad have increased the profitability of every project by 30%.

The collaborative option for Robcad as delivered from the robot builder lets you check the speed of the robot and setup cycle time of the site or line, Siuda says. "You don't have any influence to define speed of the robot as hardware, but you can write the operating program of the robot in a way that is 100% compatible with the real-life mechanical unit according to dimensions, speed and so on."

Moving Forward

Siuda says that the company will be moving to Siemens' new simulation software product before too long. "I don't think there will be any new version of Robcad," he says. "The new software from Siemens — Process Simulate — will take over the simulation market within 2–3 years, I think. AKE already has purchased its first license for this software."

Largely due to Robcad, Siuda says, AKE is no longer just another subcontractor. "The software has allowed us to move to another level of involvement," he states. "Nowadays, unlike many other suppliers, we are a partner that participates in the development of the project. We are not an ordinary subcontractor anymore."

Siuda says that right now AKE is working for one of the biggest automakers to implement a special site with only three robots to weld a complete car. "It is also very important for us that we now are designing and starting up complete lines," he explains. "This year we are implementing one site for our own use with multiple robot systems and PLCs, machine vision, etc., to explore new possibilities to implement software or functions."

Siuda also thinks that in the future, simulation and construction software will go into cloud and virtualization. "We will be doing all startup, programming, communication with the PLC, and calibration in a virtual environment. The first steps are already done."

Leaders relevant to this article: