Jim Montague is the executive editor for Control, Control Design and Industrial Networking. Email him at [email protected].

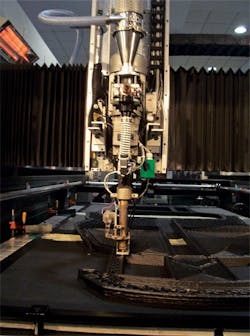

When you travel into new, strange and unknown territory, it's good to take along some friends—if not to escape all hurdles and injuries, then at least to share the setbacks and bruises evenly. This is the logic underpinning any good partnership. It was demonstrated successfully again in a recent group effort to produce the world's first 3D-printed car in just 44 hours with parts printed by Cincinnati's Big Area Additive Manufacturing (BAAM) machine at September's International Manufacturing Technology Show in Chicago (Figure 1).

The main participants printing and assembling the Strati vehicle's 40 plastic parts were Cincinnati in Harrison, Ohio; Oak Ridge National Laboratory in Oak Ridge, Tennessee; Local Motors in Phoenix; students from the University of Tennessee in in Knoxville; and the Association for Manufacturing Technology in McLean, Virginia. [For more about Strati at IMTS, read this issue's InDiscrete news section on page 18.]

Figure 1: Cincinnati’s Big Area Additive Manufacturing (BAAM) machine and its combined PLC/CNC-based controller can print carbon-fiber-reinforced thermoplastic in a 2 x 4 x 0.8-m space at a rate of 1,000 cubic in./hr.

The primary goal of the Strati project is to show that additive manufacturing can be done faster and on a much larger scale than is possible with the usual desktop, hobby-style 3D printers, and prove the technology is practical for manufacturers on plant floors at potentially high volumes in many applications and industries. However, a few well-known hurdles had to be overcome along the way.

Read Also: The Shape of 3D Printing Changes in the Automation World

"We started exploring additive manufacturing about a year and half ago, but this was going to be a big change for us because we're a pretty stodgy machine builder," says Rick Neff, Cincinnati's market development manager. "Our company is 120 years old, and we like to say that we prefer to ‘drive behind the snowplow,' but this project was going to put us way out in front of the snowplow. However, the potential for additive manufacturing is huge because there are so many applications for it. For example, we're excited about making forms for stamping sheet metal because we'll be able to 3D-print them in just days for thousands of dollars instead of waiting weeks or months and spending hundreds of thousands of dollars."

During their investigation, Neff reports that Cincinnati's engineers ran across Oak Ridge National Laboratory, which had been researching additive manufacturing for about six years, and learned its experts were bringing their additive manufacturing technology and knowhow to industrial users to help them revive and thrive.

"The typical 3D printer is small, about the size of a shoebox; slow, producing about 1 cubic inch per hour; and the material it uses costs about $100 per pound," says Lonnie Love, Ph.D., group leader of Oak Ridge's Manufacturing Demonstration Facility (MDF). "What we're seeking is a 3D printer that can produce about 1,000 cubic inches per hour of a material that only costs $1 per pound."

Figure 2: BAAM’s extruder with polymer welding equipment and modified nozzle can put down a 1/6-in. layer in the precise 60-120 °C temperature range needed for successful adhesion and high-volume additive manufacturing.

Neff adds, "Oak Ridge had a cool concept of putting a plastic extruder on a gantry system to build larger 3D parts, and we had our CL400 machine for laser-based cutting that Dr. Love wanted, and so we signed a cooperative research and development agreement (CR&DA). Oak Ridge secured $1 million in government funding, we chipped in $1 million, and we merged the two concepts into our BAAM machine."

BAAM was developed in just about one year but began printing parts only this past May. Basically, the partners removed CL400's laser equipment and added Oak Ridge's extruder to its XYZ motion platform and Z-plate assembly (Figure 2). The extruder consists of a nozzle that Oak Ridge modified and a polymer welding system from Dohle Extrusionstechnik in Germany. Oak Ridge adapted BAAM's table to go 18 in. down in addition to the 18 in. it already could go up. The table uses line shafts and ball screws at each corner to carry out G-code instructions. The three-axis machine also employs five Yaskawa servo drives and linear motors. It also has 28 temperature zones, which are monitored by Flir components and software.

BAAM is controlled by a Power PMAC controller and Motion Commander Foundation open-architecture CNC-development software from Delta Tau Data Systems, which combine PLC and CNC motion functions into one system. BAAM communicates to its devices via a 100-Mbps, fiberoptic, macro-ring network. The extruder, motion equipment and other devices all receive instructions from PMAC.

Working on truly large scale, it can print up to 1,000 cubic in. of carbon-fiber-reinforced thermoplastic per hour in a 2 x 4 x 0.8-m space, and Love adds its deposition rate likely will reach 2,000 cubic in./hr by the end of this year.

However, to achieve their goal of fast, big, high-volume, additive manufacturing, Cincinnati and Oak Ridge needed to put down layers of plastic that were much thicker than the fractions of a millimeter produced by most 3D printers.

These new layers have to be just the right size—about 1/6 in.—to maintain precise "Goldilocks zone" temperatures of 60-120 °C, so they can adhere to each other properly and build parts. Too-thin layers would be too hot, and melt and burn, while too-thick layers would be too cool, unable to stick to each other, and cause them to separate.

To solve this problem, Cincinnati and Oak Ridge enlisted help from electrical engineering intern Alex Roschili and computer engineering intern Andrew Messing, both from the University of Tennessee, who wrote the software that converts input from 3D design models into "software slices," and then all the G-code, XY coordinates, extruder settings and other commands that BAAM uses to maintain precise temperatures, print each layer and successfully build usable end products.

"We just had to make sure the 9-mm bead of plastic was separating cleanly, wasn't sticking up and dragging the previous bead, and wasn't laying down too thin and creating voids," Messing explains. "Our programming tried to create a perfect, uniform, smooth-surfaced finish."

Besides completing the 3D-printed car, proof of the partners' success was demonstrated by the fact that the second BAAM prototype that printed most of Strati's parts at IMTS has already been sold to plastics manufacturer Sabic and its Massachusetts-based research lab. This facility will reportedly use BAAM to help test and demonstrate new materials, such as the ABS plastics that Sabic produces, and may soon sell to other 3D printer users.