Radix Visual inspection technology

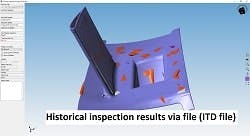

InspectTracker visual inspection technology identifies defects and maps complex part surfaces. Voice commands are used to identity defect type, which is translated to a completely digital record of inspection data. Data points are located precisely with vision algorithms, mapping the data points on a virtual part model, or digital twin. The application is designed for ease and speed of use, allowing inspectors to focus on quality assessment. Features include statistical part analysis, defects reporting, part inspection time, cost to repair, user statistics, defect analysis and failure mode frequency with heat mapping, part analysis and traceability.