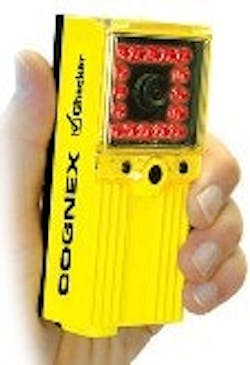

Cognex's Checker 101E machine-vision sensor

No PLC Required

Checker 101E machine-vision sensor uses patterns to detect and inspect parts. It directly accepts encoder signals, eliminating the need for a PLC when tracking and rejecting parts on variable-speed production line, and can acquire and process more than 500 images/sec. Step-by-step setup makes it simple for anyone on the factory floor to deploy.

Checker 101E machine-vision sensor uses patterns to detect and inspect parts. It directly accepts encoder signals, eliminating the need for a PLC when tracking and rejecting parts on variable-speed production line, and can acquire and process more than 500 images/sec. Step-by-step setup makes it simple for anyone on the factory floor to deploy.