Keep the Old I/O: Keep the Old I/O When Upgrading Existing Control Systems

June 23, 2014

3 min read

This article originally appeared as a sidebar in "Before Ripping Out That Old Automation System, Try Getting it Back in Shape First."

SAVE THE OLD I/O

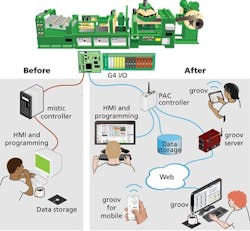

In some automation retrofit applications, the original I/O is retained, and the controller is upgraded and will work with I/O that’s up to 35 years old.

The Automate Co. in Pacific, Missouri, is a system integrator that's been building machine control systems since 1997. Barrett Davis, principal at Automate, says "I am aware of no one that's still manufactures, sells and supports I/O hardware that was being built in the early '80s. We have multiple customers for which I provided upgrades to existing machine control systems without having to replace the original I/O or field wiring." he says. His company is currently upgrading a lamination shear at Georg Transformer that cuts laminations to size and shape.The transformer division of Georg makes fabricating equipment used by transformer manufacturers all over the world. "We're updating from a 486 industrial PC controller driven by C++ and assembly language programming to an Opto 22 PAC controller. We're simply switching out all six existing parallel I/O rack cards with 32 channels of digital I/O brain cards and connecting Ethernet directly to the original rack."In addition to the new migration hardware, Opto 22 provided the command set and serial ports that let the new controller talk directly to the old equipment."One could say that the retrofit migration hardware cost is pretty close to brand new I/O hardware from Opto 22," Davis notes. "However, no shutdown is needed. Plug-and-play switchover to the new cards makes it possible to design the new program on weekends while the machine is down, eliminating the need to shut down for an extended period of a week or more."Davis notes that retrofit is used in many cases because it decreases downtime. "Many manufacturers simply do not have spare production lines, so rip-and-replace could shut their operations down if a machine is taken out of production for more than a few days," he explains. "Although this seems an insane approach, it is in fact very common."Other advantages of retrofit migration include no need to rebuild the entire control panel or reverse engineer the existing wiring and take the chance of shutting the machine down for extended periods. "We leave the wiring in place and just reprogram. The new controller can be configured and programmed just as if I were installing the new PAC brains and racks," says Davis.About the Author

Sign up for our eNewsletters

Get the latest news and updates

Leaders relevant to this article: