Can a Rewind Up Motor Efficiency?

Can you rewind (plus new bearings, etc.) a standard-efficiency motor to bring it to a higher efficiency than it was rated for? Can you approach premium levels? How about rewinding premium to approach 'super' premium? Our customer's rewinder says it can come close. If true, what does that do to the ROI advertised by the motor people? We advise them to go with new motors, but we need facts.

—From March '11, Control Design

Answers

Enough Gains Unlikely

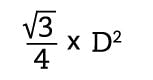

A rewind should retain the number of turns in the winding to maintain the starting and speed-torque performance of the original motor. Depending on how the original winding was inserted, by machine or by hand, it may be possible to increase the cross-sectional area of the copper when rewinding. Any gain in efficiency will then be dependent on how much additional copper area can be included in the rewind. If three perfectly round wires are touching at the edges, the lines through the centers form an equilateral triangle with sides equal to the diameter D of the wires. The area of that triangle is

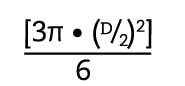

The area of the sector of each wire inside the triangle is equal to one-sixth of the area of the wire because the angles of the triangle corners are 60°. The area of the sectors of the three wires is then

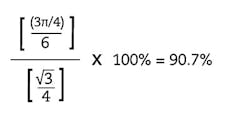

The highest level of slot fill possible using wires of the same size, without deforming the wires, is then equal to

If someone can take a "standard efficiency" (whatever that is) motor with a possible slot

fill of 60% and increase that slot fill to 90%, then the effect on stator resistance and stator losses cannot be greater than a reduction of 33%.

If the stator loss is 33% of the total loss, then the reduction in total loss is 11%. This is only approximately one NEMA nominal efficiency band. So, what is the real likelihood that someone can achieve significantly higher efficiency for a standard-efficiency motor just by packing in more wire?

The typical energy-efficient motor is unlikely to have a slot fill of 60%, so it is unlikely that the total losses of such a motor could be reduced by 10% or one NEMA band by packing in larger wire. As for achieving a premium efficiency level, consider that a 10-hp, four-pole, energy-efficient motor might have an efficiency of 89.5%. To meet a premium efficiency level, efficiency must be raised to at least 91.7%. That increase corresponds to three NEMA bands of efficiency or a reduction in total losses equal to 23%. Achieving premium efficiency by a rewind is unlikely.

Standard wire sizes differ in area by about 12.3%. Starting at 60% fill and using a single wire size, the closest one can come to 90% fill is 85%. This further reduces the likelihood of a significant increase in efficiency by changing the wire copper area.

Now, it might be possible to make some other "improvements" by changing the number of turns and trying to reduce some of the other types of losses, such as core loss, but that requires more than just a normal rewind. It also could have adverse effects on the starting performance of the motor.

And note that the above scenarios are being done by hand winding and not by high-volume production-winding equipment in a motor plant that relies on 80-82% slot fill. For hand winding, figure a 5 hp motor being wound in 2-3 minutes in production or 2-3 hours by hand. Will the additional cost offset the energy savings from the slightly higher efficiency?

None of this has addressed that when a motor manufacturer raises the efficiency, the stack length of active laminations in the motor is usually increased and the steel material is also changed to one with lower losses. Neither of these can be done in a rewind situation.

William Hoyt, Industry Director,

National Electrical Manufacturers Assn. (NEMA),

www.nema.org

Small Efficiency Gains

The efficiency of any motor can be increased if the area of the copper wire conductors in the stator winding is increased. In the case of a pre-EPAct motor, there is a high probability that this can be done. In most cases, though, the increase in efficiency will be less than half of a percentage point of efficiency, which would not be enough to change the efficiency to EPAct or premium levels.

For example, a 50 hp, 1800 rpm TEFC motor at the NEMA premium level would have a nominal efficiency of 94.5%. Historical data for pre-EPAct motors used by the U.S. Department of Energy indicates a typical nominal efficiency of 91.3% for this rating. The difference in efficiency would be 3.2%, thus far greater than the 0.5% maximum approximation.

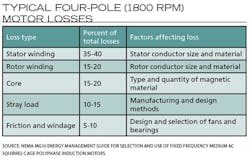

The primary reason for the relatively small increase in rewound motor efficiency is that stator copper (winding) losses, although usually the largest component in motor losses, are typically only 35-40% of the total losses (table).

The windings tend to be tighter in the slots in EPAct motors than they are with pre-EPAct motors, thus reducing the potential for efficiency improvement by increasing wire area. To illustrate this point, the EASA/AEMT Rewind Study (www.easa.com/energy) found that the most common efficiency improvement for rewound EPAct motors using the good practices detailed in the study was 0.2 percentage points. The windings of premium efficient motors typically either do not have slot space available to allow an increase in wire area, or their wire area per amp of rated current is so great that an increase in wire area would have a negligible effect on efficiency.

To summarize, pre-EPAct and EPAct motors can be rewound and the efficiency improved by up to a half percent if the wire area of the conductors can be increased. Most premium motors are probably not candidates for efficiency improvement because of the reasons in the prior paragraph. It is not possible for a rewind to improve the efficiency of a pre-EPAct motor to the premium level, and it is almost never possible for a rewind to improve the efficiency of a pre-EPAct motor to the EPAct level.

All this said, installed motors should be examined to determine whether repair/rewind or replacement is most appropriate based on a variety of factors, including annual operating hours and the specific application.

Thomas Bishop,

Senior Technical Support Specialist,

Electrical Apparatus Service Assn., www.easa.com

Promises, Promises

I think that a rewinder can do only one subtle tweak to make any change, and that change is small (if possible at all). It could use thicker wire to lower resistance, which could help the motor run cooler, in turn helping efficiency, but does the stator slot design permit this tweak? If you reduce copper losses by making the winding heads smaller, that could help, but that takes mechanical care during the rewind process. Also, what is the rewinder doing about laminations, rotor design, windage and friction losses? I know some of those are secondary losses, but without hard data from testing, I would not believe any large promise.

I also believe that the rewound motor efficiency still would be lower than that of a new energy-efficient motor because of the efficient motor's unique physical characteristics and materials used:

- Higher-quality alloy and thinner steel laminations in the stator

- Higher fill factor of copper in the windings

- Optimized air gap between the rotor and stator

- Reduced fan losses

- Closer matching tolerances.

Energy-efficient motors can be rewound to maintain their original efficiency as long as proper tools and procedures are used. However, it would be difficult to go any higher because of the thermal aging of original components. In fact, it is more common to see efficiency slightly dropping from original levels.

Some considerations to keep in mind when deciding on rewinding or buying a new efficient motor:

- A quality rewind can maintain original motor efficiency. However, if a motor core has been damaged or the rewind shop is careless, significant losses can occur.

- Motors less than 100 hp and more than 15 years old (especially previously rewound motors) often have efficiencies significantly lower than current models. It is usually best to replace them.

- If the rewind cost exceeds 65% of a new energy-efficient motor price, buy the new motor. Increased reliability and efficiency should quickly recover the price premium

Abdulilah Alzayyat, Product Manager,

Bosch Rexroth, www.boschrexroth-us.com

Variable Savings

Although these ratings refer to AC induction motors typically used in fan, pump and compressor applications, the most significant impact on energy savings is likely the application of a variable-frequency drive (VFD) to the existing motor. This would typically reduce the energy consumption far more than rewinding a motor to Super E ratings because the power draw of the motor is related to the third power of speed.

The highest-efficiency option would be to provide a permanent magnet servo in place of the AC induction system, where not only is the motor more efficient than the AC induction motor, but the power output can be optimized by varying the speed in real time to match the output requirement.

Tom England, Director, Global Product Planning,

Kollmorgen, www.kollmorgen.com

Consider Your Losses

In general, it is not possible to improve the efficiency of a motor once the design is set. There are five losses in an induction motor to consider.

Core Loss—If not damaged during burnout, the core will maintain its properties or may be slightly degraded. In any case, there will not be less loss than the original motor prior to burnout.

Friction and Windage—Bearing size and type should remain the same. The cooling fan size and type will remain the same. So there should be no change in these losses.

Stray Load Loss—There are many components to stray load loss but, in general, there is no change in the construction of the machine. Any components related to the basic motor design, such as slot combination, will also be unchanged. It may be possible to re-machine the air gap to reduce one component of stray loss, but unless it is done with precision (not smearing the laminations) this benefit could be negated. So, no real change here either.

Rotor Conductor Loss—There will be no change to the conductor material, bar shape or end rings, therefore no change here.

Stator Conductor Loss—More copper could be added to the slot only if the slot had low fill to begin with. In general, unless the motor is very old, manufacturers tended to fill the slots in response to meeting EPAct in 1995. Just manipulating this loss during the rewind likely will not reduce the total losses of the motor enough to meet the NEMA Premium level.

Helmuth Glatt,

Vice President of Engineering,

Nidec Motor, www.nidec-motor.com