OEMs Are Retaining Automation Knowledge by Documenting, Sharing and Reusing It

The customers of machine and robot builders demand more nowadays, from lower cost to higher performance and greater flexibility. Machine builders must meet those demands while dealing with inevitable internal constraints.

The most important of these constraints is finding the right people to design and build their machines. "The availability of design engineering resources is a constraint to growth," says Craig Souser, president of JLS Automation (www.jlsautomation.com) in York, Pa. JLS provides robotic-based automation systems for primary packaging applications, with a major focus on the food-processing segment.

The push toward greater integration between IT and automation exacerbates the problem. "Our automation engineers need both IT and networking knowledge," notes Ryan Thompson, automation and electrical supervisor at Wolf-tec (www.wolf-tec.com) in Kingston, N.Y. Wolf-tec is an OEM in the meat and poultry and fish-processing industries. "We've discovered that more and more automation decisions are made by our customers' IT departments," adds Thompson. "Having people with an IT or computer programming background also helps us with newer technologies such as class and control development that have been a standard in computer programming and are starting to be used in machine programming.

So machine builders need excellent automation engineers with IT experience, but that's not enough. "Automation professionals need an understanding of the impact that their designs have in the manufacturing world," says Robert McConnell, controls engineering manager at Kuka Systems (www.kuka-systems.com) in Sterling Heights, Mich. Kuka is a manufacturer and integrator of tooling and robotic applications. "It's relatively easy for a controls engineer to design a new tool and hand it off to manufacturing, but to take an existing tool and provide a design that simplifies installation takes a bit more foresight," adds McConnell. "One needs to consider the entire scope of work."

So an automation professional needs to know automation, be strong in IT and understand the customer's entire manufacturing process. It goes without saying that the best automation pros must also know their own machines and robots inside out.

The brute-force way to deal with the resource constraint is to find a large number of superstars and hire them. This is, of course, extremely expensive to the point of not being entirely realistic.

A more intelligent approach is to create machines that can be developed and maintained by fewer highly skilled automation pros using a team approach. These products are easier to build and simpler to maintain. This approach requires an entirely different method of designing machines, one that relies on standards and modules instead of custom designs.

Heroes Are Hard to Find

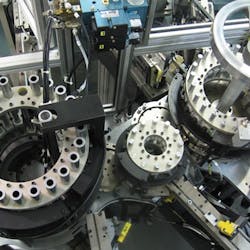

Haumiller Engineering (www.haumiller.com), Elgin, Ill., carved out a niche in high-speed, automated assembly machines, often in the form of continuous motion (Figure 1). Haumiller's top goal is reliable, accurate machines that exceed performance expectations. "But consistency is also important," says Pat Phillips, Haumiller's engineering manager. "No matter who works on a project from engineering or production, the results should be the same. So standards and modular design become even more important."

Figure 1: Standards and modular design enable Haumiller's approach to designing high-speed, automated assembly machines so that, no matter who works on a project from engineering or production, the results should be the same.

Phillips says it can be very difficult to design or construct machine modules or segments in advance. "What we can do, however, is document and use standard methods to execute specific controls and design tasks, to debug our processes in-house and to handle customer changes."Besides the standard methods it follows, Phillips says Haumiller is lucky to have a very robust experience repository. "This isn't just people," he states. "It's drawings and solutions logged over 45 years in the high-speed, continuous motion business. If we get a project, often we have ideas for solutions in the first five minutes. While custom solutions are most of what we do, prior methods and solutions are often applicable, lowering the risk of an automated assembly project."

Designing a custom machine for each project is the most straightforward and often lowest-cost method of producing a product. The product does only what it's supposed to do and no more. "Unfortunately, single-purpose custom machines that can't be retrofitted easily for different applications are not saleable," says Pavel Bouška, area sales manager for Velteko CZ (www.velteko.cz) in the Czech Republic. Velteko makes vertical form fill and seal packaging machines and accessories.

Standards Require Investment

Bradbury (www.bradburygroup.com) in Moundridge, Kan., builds machines for metal forming and coil processing, with its largest customers in the metal building and garage door industries (Figure 2). It calls its approach "total system control." It consists of a control solution framework, a control system architecture and control solution standards.

Figure 2: Bradbury's Quick Telescopic Rollformer, designed and built using an approach called "total system control," produces purlins used in the construction of metal buildings.

The control solution framework identifies project deliverables, milestones and team member responsibilities. The control system's architecture defines the hardware components, software components and communications, as well as the overall design and construction of the automation system. The control solution standards are based on collective years of internal controls experience, along with industry standards and best practices."Our team members work together to develop a solution that we all can maintain and support," sums up Larry Asher, controls engineering manager at Bradbury. "It's a process designed to make us more efficient by reusing existing solutions. Designing a system for reuse requires more time up front, since you have to consider all known variations and do your best to predict the future. This is an overwhelming task if there are no limits, so it's necessary to have a vision for your automation system and everything you want it to be."

Companies have different labels for their standards programs, but all agree that significant investment is required. "We invest a lot of up-front time to develop highly structured intelligent systems," notes Tim Jager, project director at DMC (www.dmcinfo.com), a system integrator based in Chicago. "We use an object-oriented approach to software design, including modularity, encapsulation of code and well-organized data structures. We take the time to design each system so that it can be reused easily."

Reusability is a clear objective for machine builders. "The goal of automation builders for the past three decades has been to be able to draw from a set of standards to create custom solutions," says Chris Lovendahl, sales manager, Concep Machine, Northbrook, Ill. "Market forces also contribute to this need, among them the compression of the manufacturing phase in the schedules for new product launches, price pressures from adoption of online, reverse-auction purchasing by the automotive industry and migration of engineering talent from traditional manufacturing jobs to high-tech manufacturing jobs."

Technology has contributed to the promotion of standardization at Concep in several ways. "Tremendous advances in CAD—from replication of drafting in electronic 2D to streamlined, fast 3D—have reduced the need for engineering rework of parts that interfere or do not fit together in the build phase," says Lovendahl. "Plug-and-play device technology enables simpler bus connection of the hundreds of devices that are integrated in a custom machine (Figure 3). Further, the solid models make it simple to add them to the CAD design."

Figure 3: The goal of custom machine builder Concep Machine, for the past three decades, has been to draw from a set of standards to create high-performing solutions.

Avoiding proprietary solutions helps customers reduce maintenance costs. "For our application, we need a controller with flexibility and programmability," says Amir Khajepour, founder and president of AEMK Systems, Waterloo, Ontario, and also a professor in the Department of Mechanical and Mechatronics Engineering at the University of Waterloo. AEMK (www.aemksystems.com) makes high-speed cable robots with an optional vision control system for use in flexible and fixtureless automation lines (Figure 4). These robots have arms made of steel cables instead of rigid metal, thereby reducing moving inertia, cutting cost and lowering maintenance."We also require compatibility with a wide range of digital and analog input/output cards, motor drives and encoders," adds Khajepour. AEMK uses off-the-shelf components, including Beckhoff Automation controllers and drives.Creating standard robots that can be deployed in a wide variety of applications requires up-front effort. "Parallel robots have complex kinematics, so we've developed our own controller loops to maximize robot performance. These loops were developed using an off-the-shelf controller along with its PID and input/output libraries," concludes Khajepour.

Figure 4: AEMK's high-speed cable robot for use in flexible and fixtureless automation lines requires compatability with a wide range of off-the-shelf components.

A case in point for standardized modular solutions is a recent project DMC completed for a Tier-1 automotive engine assembly-line equipment supplier. A bare engine block starts at the beginning of an assembly line and makes its way through each station, ultimately ending up as a complete engine. At each station one or more components are added to the engine.The challenging aspect of the process is that each engine can be different. A particular make of car could have 20 or more different engine combinations. Depending on an engine's build manifest, each station in the assembly line might have to perform different actions.

"We wrote a highly modular and flexible system from the ground up that didn't require a programmer for software maintenance," says Jager. "All of the sequencing logic is user-configurable and stored in a recipe system. The end user can modify any of the sequences completely by using an intuitive configuration screen in the software. When sequence changes are requested, the user simply goes to the sequence editor page and makes the appropriate changes, often in a matter of minutes."

Rare is the case in which Haumiller can reuse a complete existing design—except for the standard product line that accounts for about 25% of its business. "When we can reuse a portion, it often is for an existing customer where the machine is going to the same plant," says Phillips. "Often our customers have greatly differing specs from plant to plant for virtually the same piece of equipment."

However, adds Phillips, even though it is extremely rare that Haumiller would ever repeat an existing machine, "we're always repeating methods, modules, programming and other ways of doing things. The trick is to have a system that uses pieces from previous machines, projects and customers."

Standard electrical schematic blocks, logic blocks and an index provide reference to data and shared institutional knowledge, "whether you've been with the company for years or only recently," says Phillips. "When we get a project in house, the first thing we go to is our reference index and menus to look for programming similar to what we'll need. For some aspects of a new system, we can reuse a previous design or solution." Direct reuse, he admits, represents a small percentage of any new project.

Team Players Needed

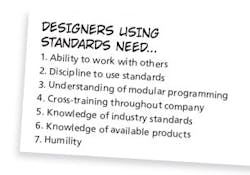

Besides investment, standards programs also require a different type of employee mentality.

"This is not a black-and-white topic, but rather a general goal that needs to be agreed upon and reinforced and monitored," believes Phillips. "Creative people will tend by nature to customize 100% if not coached on the benefits of reusing a percentage of existing designs."

Sometimes, adds Phillips, the customer needs to be educated that with some specification concessions, complexity can be reduced and costs lowered. "A simple design change sometimes can transform a project from one that's mostly from scratch to one in which many concepts from previous projects are reused. Careful collaboration between the customer and our team will help reveal these opportunities and see if they make sense in each specific instance."

CBW Automation (www.cbwautomation.com) in Fort Collins, Colo., manufactures high-speed retrieval systems for injection-molding applications. Vice president of customer support Steve Corwine describes how teamwork enables reuse of automation know-how at his company by "using standard designs and existing components and merging them to complete a unit, per the requirements of the project. Standards allow us to use junior designers instead of senior engineers. The more senior personnel are freed to do more advanced design for custom systems such as complex end-of-arm tooling."

Reusing standards requires the team player to work with others across the industry, and reuse of know-how created elsewhere requires engineers to put aside ego and appreciate that many of the best solutions already exist. But does resuse somehow limit creativity and innovation? "I've found the opposite to be true," observes Bradbury's Asher. "We now have more time for innovation vs. redesigning the same old functionality over and over again."

Mad Skills

To deal with skill sets needed by machine automation engineers to reuse existing best practices, and which might differ from those needed for completely new designs, Concep's engineers work on both types of projects at some point. "As I mentioned, the development of new programs requires that our engineers be experienced with developing programs that can be used in the future with as little additional engineering as possible," says Lovendahl. "So those new programs rely on prior engineering experience. Most of the time, our less-senior engineers start by learning our engineering practices through the projects that only need modification to existing programming. With time, they move on to writing new programming. In addition, development of new programming is an enjoyable task for our experienced engineers who like a change of pace in their project loads or want to update themselves to what is going on the industry by looking at the state of the art."

Phillips doesn't see much difference in skill sets, saying "it's the recordkeeping system that makes reference and documentation of existing designs essential. The discipline to correctly document all designs is vital. This has to be a cultural goal within the company."