OI With Calculator Cards a Hole in One

By Darrell Fiegenbaum, Kays Engineering

The need to drill straight and true holes is a staple of manufacturing. Ever since since the production of handguns and rifles began, the precision benchmark has been set high for deep hole drilling. Even today, these systems are called "gun drills" because of their origins—gun and rifle manufacturing was one of the first applications to require ultra-high drill precision. Yet, this drill technology has moved into many other industries, such as automotive, aerospace and medical—basically, any application that requires precision holes.

Kays Engineering is a provider of high-precision, deep-hole drilling systems. With customers located in North America and around the world, Kays Engineering must remain at the forefront of automation technology to meet the extremely high-precision requirements and diverse drilling needs of its increasingly international customer base.

We manufacture two well-established deep hole drilling systems—the Eldorado and DeHoff machine families. The main difference between the DeHoff and Eldorado lines is drill size. The Eldorado line is the smaller of the two, with drill diameters up to ¾-in. The DeHoff's drill sizes have a much larger range. In contrast to Eldorado, DeHoff tightly incorporates control of the coolant system, fixturing system, automation system and many other optional components into the machine control, according to specifications required by the customer.

In recent years, the Eldorado machine has been widely adopted in the medical field. These machines are used to drill holes in bone screws and other medical replacement parts. The DeHoff machines tend to be the machine of choice for gun-barrel manufacturing, engine part design and manufacturing, or in a cell of machines as part of metal extrusion processes.

A major competitive differentiator with DeHoff machines is the use of flat-ground ways rather than linear guide ways. This provides stability and helps minimize vibration in the drilling process, which could otherwise cause many quality problems in the finished product. DeHoff machines also offer a range of spindle speeds to provide drilling flexibility.

The primary customer requirement for our machines is that they be highly adaptable and flexible to every unique application. "While Kays offers a job shop-oriented and standardized machine with the Eldorado line, the DeHoff line of drills is often subject to requests for customization," says Brandon Snell, controls engineer, Kays Engineering. "Usually our customers already have finished the design and dimensions of their parts that are to be drilled. We must be totally flexible to adapt our machines to faultlessly drill parts that have nearly limitless variance in shape and size." The DeHoff gun-drill line has standard elements such as the servo drives, motors and other standard motion components, but the machine is very application-specific.

Ace in the Hole

Kays Engineering recently commitedd to using PC-based programming and control. The major reasons for this choice were programming flexibility, ease of networking and standardized interfaces. Previously, we used PLC-based controls from companies such as Rockwell Automation. However, the ability to have integrated motion control without a full-blown CNC control became very desirable. We compared solutions from different companies, including Rockwell, Beckhoff, Siemens and GE. We concluded that Beckhoff's direct-sale approach, pricing, excellent customer support and international market appeal would give us the competitive edge we were attempting to provide.

We selected the CX1010 embedded PC with a 500 MHz Pentium MMX-compatible processor for both the Eldorado and DeHoff machines. This selection gave Kays Engineering flexibility, as well as a standard platform. The CX controllers use EtherCat. "Another benefit of the embedded PCs is that they use Compact Flash for boot and memory," says Snell.

One of the major benefits of the redesigned machines was the display upgrade and what the design allowed the interface to do. The previous grayscale, low-resolution displays were replaced with full-color 6.5-in. control panels with custom Eldorado logos and 12-in. panels with custom DeHoff logos.

These control panels feature numerous function keys and a numeric keypad, adding to the flexibility of the new display. The panels connect to the CX embedded PCs via DVI/USB. The 6.5 in. panel is an IP65-rated display that does not require a control panel enclosure. It can be mounted directly to machines via a pedestal or swing-arm mounting configuration with all peripheral cables concealed and routed through the mounting tubes (Figure 1). The CX1010 runs TwinCat NC PTP software giving Kays Engineering integrated motion control functionality.

Figure 1: The full-color control panel is an IP65-rated display and can be mounted on the machine via pedestal or a swing-arm mounting configuration.

KAYS ENGINEERING

Figure 2: Visualization software, which is integrated with the control software, gives Kays the flexibility to create its own HMI, with no concern about software elements functioning together properly.

KAYS ENGINEERING

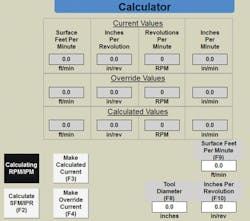

The ability to choose structured text with the Beckhoff system has greatly streamlined our programming. "While we still can use ladder logic, we're not restricted to it, and can program in all the IEC 61131-3 languages," says Snell. "That one line of code can handle an entire complex equation really helped out. In the past, there were occasions when I had to code averaging calculations in ladder. Having 'addition' in one rung and 'division' in the next, and then storing it in another rung isn't as easy as typing out the formula that I know." The system we created includes a "drilling parameters calculator" that lets operators simply enter data on the material to be drilled, along with the required hole diameter. The system automatically generates the appropriate starting point for the feed rate and spindle speed for the materials to be drilled (Figure 3).

Job shop-oriented companies benefit most from the calculator. It makes it simpler to switch parts that are being drilled by saving the operator time on making the calculations needed to determine the best starting place for the feed rate and spindle speed. It is also very useful for customers just now getting into the deep-hole-drilling business because an operator can run a machine without a lot of previous knowledge about deep-hole drilling. Even those customers of ours who have been making the calculations by hand for years have been using it to check their numbers, and make it easy for them to load these parameters into the machine. "Program storage and file saving has become much simpler with our new PC-based control system," says Snell.

Drill for Details

Overall, the new Eldorado and DeHoff control systems have become more economical than the previous systems. In addition to the higher performance, energy use has been reduced by using more efficient servo drives. "Today, there's a more compact motor controlling the gun drill's axis slide that can generate the same level of torque as the larger motor in our previous system," says Snell. "And the improved flexibility and efficiency didn't come with an increased cost. We saw a dramatic controls cost optimization with the DeHoff machine. The new control system with the CX1010 costs 50% less than the previous traditional PLC-based system," says Snell. "On the improved entry-level Eldorado machines, the new control system permits slightly scaled-down PC-based hardware, but uses the same TwinCat NC PTP control environment. The Eldorado system costs 10% less than the lower-performing system it replaced."

The savings did not stop at hardware cost. "Using EtherCat and standard Ethernet cabling, we cut two entire work days from the required wiring time of our Eldorado and DeHoff control cabinets," says Snell. Customer reception for the new Eldorado and DeHoff machines has been equally positive and highly encouraging. "As a result of the strong feedback for these redesigned machines, at least 90% of the Eldorado and DeHoff machines will be fully equipped this way going forward," adds Snell.

In addition, Kays Engineering has by no means reached the end of its PC-based control evolution. Over the past year, we've continued our push toward standards and ease of use for both our electricians and our customer's maintenance personnel. One major change was using an EtherCat connection to the VFD for the DeHoff machines. This allows configuration and commands to be sent to the VFD without needing the additional Modbus/TCP library. We're also currently researching the possibility of an EtherCat-connected linear scale. This should help control the noise and simplify wiring. It also puts the conversion of signals directly into the scale, which simply provides us with an absolute position and rate of change. This simplifies programming, as well. The CX1020 and CX1030 embedded PCs provide even higher performance options and room to grow when we decide to add more axes of motion and further enhance the system features of the deep-hole drilling systems. "We have the ability to simply scale up to the next controller in the CX family," explains Snell. "Most of the existing programming and control design will remain the same for each new machine variant. We've optimized our machine design flexibility today and well into the future."

Darrell Fiegenbaum is controls engineer at Kays Engineering (www.kays-dehoff.com) in Marshall, Missouri.