Builder Puts the Custom in Customer

Haumiller Engineering (www.haumiller.com) in Elgin, Illinois, has been in the custom assembly machine business for 45 years, serving consumer packaged goods, medical device and other industries. "Our company is 100% employee-owned, meaning that everyone has a vested interest in our customers' success," says Pat Phillips, engineering manager.

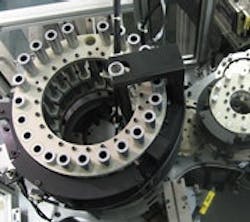

Approximately 90 employees meet the needs of Haumiller's globally installed machine base—primarily high-speed, highly automated assembly machines—but accompanying tasks often include testing, inspection, tube application, closing and processes such as die cutting, hot stamping and sonic welding.

"All inspections are automated and rigidly designed to ensure the highest possible quality to the end customer," explains Phillips. "Our typical customer asks for equipment-part-per-minute output often higher than what has been done before on similar equipment. This is where the custom part of Haumiller's business comes in, and it makes up about 75% of the work we do. We're solving a one-of-a-kind automation problem that has never been solved before. The remaining 25% of our business is a standard line of automated assembly machines consisting of aerosol tippers, cappers and valve placers."

HAUMILLER ENGINEERING

Continuous motion is the method most Haumiller machines use for moving parts through the process. "Unlike indexing, which uses a dial that stops and starts at each station in the machine, continuous motion never stops moving in a very smooth and calculated manner, which preserves both the machine itself and the parts that are moving through it," says Phillips. "In continuous motion, multiple processes occur without interruption for every cycle, effectively overlapping. And because the tooling never loses contact with the individual components, part alignment is maintained during assembly."

Engineers comprise more than a quarter of Haumiller's workforce. "The applications engineers are the link between our sales group and the concept engineers," explains Phillips. "They develop the initial machine concepts that are used in the quoting process to determine feasibility and cost. The mechanical engineers are further broken down into concept engineers and mechanical design engineers. The concept group develops a machine concept when we are initially given a new product, and the mechanical design group executes on that concept to achieve the final machine. The controls engineers work on everything from the electrical and pneumatic controls of our equipment to the development of all machine programs."

Haumiller achieves motion control using three-phase ac motors, servos, steppers, pneumatics and robotics, says Dennis Fox, controls engineer at Haumiller. And Haumiller's inspection controls include discrete sensors, vision, pressure/flow, weighing/counting, torque and functional testing.

"Most of our machine controls are hardwired," explains Fox. "There are some right now using digital networks through EtherNet I/P, Profinet or Modbus TCP, but currently no wireless controls."