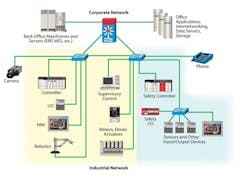

To some extent, this proliferation of networks and protocols is needed to meet application requirements, but the sheer multitude of options can be baffling to standards makers, OEMs and end users. This article will sort through available options, adding order to chaos.

One level down are instrument and sensor networks. Instrument networks typically are used to connect instruments and analyzers to HMIs and controllers, and sometimes directly to enterprise-level computing systems. These networks are optimized to transfer relatively large amounts of data at relatively slow speeds, making them a good fit for process control applications.

Sensor networks typically connect discrete sensors to controllers, and connect motor controllers to a main controller. These networks often carry power along with signals on the same wire. High speeds are possible because of the relatively small amounts of data transfer, making these networks a good fit for the discrete sensors and I/O often found in machine and robot builder applications.

Overlaying all three network levels is wireless, with myriad competing standards. Some of these standards are optimized for one level, such as WirelessHART for instrument-level networks. Others such as wireless Ethernet cut across multiple levels.

In the process industry, wireless gained a foothold primarily because of the cost savings over wired cable, says Richard McCormick, automation engineer at Mick Automation in Levis, Quebec, an industry consultant with extensive plant operations experience. "Wireless is definitively the biggest trend in automation these days, at least for monitoring," McCormick says. "The advantages are cost savings in wiring, and providing access to places so remote they were simply rejected every time a project looked at bringing those signals inside the DCS."

Rob Kearney, maintenance supervisor for North Star BlueScope Steel in Delta, Ohio, uses 32 wireless temperature transmitters to monitor furnace operation (Figure 3). "The new wireless solution eliminated almost 100% of the cable and conduit, while reducing maintenance costs by $200,000 annually," he says.

In the discrete manufacturing automation sector, wireless is used, again primarily for monitoring as opposed to real-time control applications. "Wireless makes it easier to communicate between devices when it's often not practical and/or feasible to run a hard-wired communications cable," says Sam Hoff, president of Patti Engineering, an automation systems integrator in Auburn Hills, Michigan.

But wireless has made little impact on many users, maybe because some are a little timid. "Wireless in the plant delivers a new way to provide proof-of-concept for large automation projects," says Tom Edwards, senior technical advisor at Opto 22. "Before investing in permanent wiring or building a full-blown wireless infrastructure throughout the factory or facility, people have begun dipping their toes in the water by using wireless components in one or two remote areas."

In other words, wireless is being used primarily for monitoring purposes in both process and discrete automation mainly because it costs less than hardwiring. Otherwise, users and OEMs seem reluctant. Maybe this is because automation engineers aren't comfortable with the technology or the multitude of standards.

In the process control world, the standards makers are battling once again, and users don't like it, writes Walt Boyes, editor in chief of sibling Control magazine, in "Convergence-or Not. That's the Question." "A group of large end users…told the major automation vendors that they were tired of wireless wars, and they wanted a sincere convergence effort between WirelessHART, now IEC 62591, and ISA100.11a-2009." Now that the Chinese WIA standard has been approved by IEC, we are very close to having four standards, Boyes notes.

There's even more confusion for users, according to Carl Henning, deputy director of Profibus and Profinet in North America. "One of my pet peeves is that there's more than one kind of wireless," he laments. He classifies them as backhaul (proprietary radio to RTUs), process instruments (WirelessHART), sensor and actuator (IO-Link) and Ethernet wireless (Wi-Fi and Bluetooth). "I think many people miss the fact that different types of wireless applications have very different requirements."

Despite the confusion, some observers see light at the end of the tunnel. "The IEEE 802.11n (Wireless-N) standard appears to provide the stability missing from previous standards for widespread use in manufacturing," says Brian Oulton, director of networks business at Rockwell Automation. "This moves the industry from implementing wireless for special situations to having a common user experience, whether wired and/or wireless. Soon you'll be able to use a wireless notebook computer, industrial computer or commercial appliance for information access along with real-time control between robots, programmable automation controllers, I/O drives and instruments."

Multiples of Ethernet

In general, Ethernet has widespread acceptance and penetration in manufacturing, along with many satisfied users. "Ethernet has provided greater standardization between various manufacturers' products, and more use of web-based monitoring and reporting," notes Hoff of Patti Engineering.

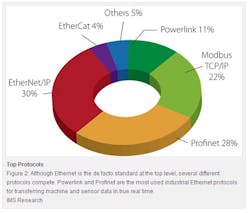

Although there is general satisfaction with Ethernet, vendors and organizations still found the need to develop specialized Ethernet protocols. Figure 2 shows the top industrial Ethernet protocols. Popular protocols such as IO-Link didn't make the list. Neither did BACnet, despite its dominance in building automation.

One problem for end users, machine OEMs and system integrators is that they don't know who to believe. IMS Research conducted the study, "The World Market for Industrial Ethernet—2009 Edition," from which Figure 2 was taken, and says that Powerlink and Profinet are the world's most used industrial Ethernet protocols for transferring machine and sensor data in true real time.

"Traditional robots often are called industrial robots, and are used mainly in factories," says Makoto Mizukawa, dean of the College of Engineering at the Shibaura Institute of Technology in Tokyo. "Recently, robotics technologies developed service robots, which perform operations similar to human beings."

Whether of the industrial or service variety, robots need to recognize various objects and respond accordingly to dynamically changing environments or situations to work near humans safely. A new approach for robotics development could help.

In this approach, robots are divided into robotics components such as servo motors, sensors, cameras and so on. Those elements are combined into a complete robotics system. Robotic technology (RT) middleware software is being developed as a platform on which RT components run. The idea is that each vendor can concentrate on building parts, which they are good at, and not worry about how the robot system fits together.

What each RT component must provide is defined in the standard Robotic Technology Component (RTC) specification by the Object Management Group (OMG), an international, not-for-profit consortium that standardizes object-oriented technologies.

RTC-CANopen is a profile for using CANopen to communicate among RT components. This profile describes the information needed to make CANopen devices work as RT components. "RTC-CANopen enables mutual collaboration between various devices connected to CANopen, and among RT components running on general-purpose networks," Mizukawa explains. "It becomes easy to combine them and build a robotic system."

The RTC-CANopen profile is defined by adding necessary information for devices to run as RT components to the existing CANopen profile, Mizukawa notes.

Another problem for industrial users is that Ethernet hardware hasn't been very industrial until recently. Many of the products offered for industrial use were simply office-grade devices. That seems to be changing rapidly.

"When we introduced our gigabit control network in 2005, there were no switch manufacturers making Class 1 Div 2 gigabit switches," explains Bruce Jensen, manager of systems marketing and solutions support at Yokogawa. "Now, in 2010, we've qualified more than six manufacturers with multiple models that can be used with our system."

Switches are getting tougher, too. "We now have a choice for equipment in Class I, Div 2 environments," Jensen says. "In addition, the switch manufacturers added redundant power supplies, 24 Vdc power sources and other hardened components to withstand plant environments better."

The Power of PoEFurther complicating the scene, and maybe posing a threat to wireless, is Power over Ethernet (PoE). With PoE, the Ethernet cable carries enough electrical power to run devices, similar to how 4-20 mA wiring powers a transmitter in instrument applications. Venture Development predicts that shipments of PoE-enabled Ethernet switch ports will double by 2012 as users and OEMs become aware of the benefits.

We might speculate that if the most compelling reason to use wireless is the eduction in wiring costs, then could PoE provide a similar benefit? Remote devices such as instruments and sensors need power, and if PoE can provide it, that eliminates a large part of the wiring expense.

Ethernet has been around the industrial scene for many years, and has overcome technical objections. This seems to be the case today with faster, more-rugged switches and PoE. Even so, specialized communications protocols and systems continue to proliferate.

Maybe they can work together. Jensen says he sees a pattern. "The trend is the acceptance of multiple protocols and networks in an installation," he notes. "Some installations will have HART or Foundation fieldbus and sometimes Profibus for analog signals, DeviceNet or AS-i bus for discrete, DeviceNet or Profibus for motor control centers, and Modbus/TCP for subsystems."

Instrument Networks and Device-Level BusesWith proprietary networks from major instrument vendors disappearing, process control users essentially have three instrument networks from which to choose: Foundation fieldbus, HART and Profibus. Unlike the other two, HART uses the 4-20 mA wire to send digital information.

Mick Automation's McCormick says Profibus and Foundation fieldbus are popular in process control, basically for the same main reasons as wireless: cost reductions through less wire and cable. "But they are also popular because of reduced commissioning time during implementation, and easier and better instrumentation preventive maintenance once in operation," he adds.

Device-level buses connect discrete devices to PCs and PLCs, and are primarily used in machine and robot control applications. Phil Hillard, electrical engineer at Rennco in Homer, Michigan, has used device buses since the technology was introduced. Rennco makes packaging machines and handling systems. "DeviceNet was the first network that offered a variety of vendors for peripheral devices," Hillard notes. "The networking allowed machine manufacturers to design truly modular components that could be interchanged to offer variety in their machine applications."

Hillard used DeviceNet to reduce the amount of cabling necessary when using remote devices, and to help design the individual pieces of a large system comprised of several component parts. "The DeviceNet approach allows us to completely wire each component," he explains. "The individual pieces are gathered and their cables connected to DeviceNet."

CAN bus was popular earlier and to some degree had multiple vendors, but not as widespread as DeviceNet, Hillard opines. "I believe it's more popular in the European arena."

If all this talk about multiple protocols, profiles and conformance testing has your head spinning, be advised that you still can use serial. With the rise of Ethernet, one might expect a steady decline or perhaps even the slow death of serial," says Opto 22's Tom Edwards. "Yet serial-based industrial networking applications continue to exist and new ones are implemented all the time."

Why hasn't serial been abandoned? "Ethernet has a few inherent limitations that serial doesn't," he explains. "One is distance. When you get past 100 meters, signals carried over Ethernet almost always begin to degrade. With RS-485 serial, on the other hand, signals can travel significantly longer distances at relatively fast rates. Serial also continues to thrive because there are far more inexpensive field devices, such as barcode scanners and badge readers, that communicate over serial. This makes serial perfect for many applications in which you want to wire up your end device quickly and immediately begin to send or receive data or exercise simple control."

Modbus is one of the oldest serial networks still in use today, and it has many followers among users and vendors, because it's so simple and inexpensive to use. New devices, bristling with Ethernet ports, often come with a Modbus port too.

Olivier Suc, project manager at Good Manufacturing Practices, a process control system integrator in Exton, Pennsylvania, says fiberoptics really help Modbus. "The use of fiberoptic cables enables noise immunity and greater distances," Suc says. "Modbus always has been a slow protocol and the longer the run, the slower the baud rate. So by being able to carry Modbus over fiberoptics, the distance almost isn't a factor anymore. A standard connection was limited to 1,200 ft, whereas with fiber you can go 2 km without a repeater."

The development of device, interface and application profiles is a large technology influence on networks, Zeltwanger says. "Profiles specify the content and application behavior," he explains. "LON and Interbus were the first communication technologies introducing profiles. The most profiles are available for CIP in DeviceNet and EtherNet/IP, as well as for CANopen, with more than 50 profiles."

Robots are getting so sophisticated, they need their own RTC-CANopen profile, as described in "Robot Communications".

Do They Really Work Together?

Users and machine OEMs probably are puzzled at this point. All they want to do is install a network that will connect all of their devices, but there are many choices to make among wireless, Ethernet, instrument networks and device networks. How does a user know what will work?

At the instrument level, the Profibus, HART and Foundation fieldbus organizations test instruments and analyzers to verify they comply, and then issue certifications. Theoretically, this ensures that a transmitter from Vendor A will work on a fieldbus system supplied by Vendor B. As many process control users can attest, it ain't necessarily so, but conformance testing and compliance is a good start.

"Official conformance testing costs money," Zeltwanger says. "Those costs can be reduced if the products are tested at plug-fests." At such an event, multiple vendors gather in a single location to see if their devices will work with each other.

Maybe a Bit of OPCIf all else fails, OPC might help. OPC doesn't solve hardware problems between two networks; it makes them work together with OPC software drivers. So when faced with the problem of connecting Device A to Device B via two different (or the same) networks, there's a good chance OPC software can make the connection.

"OPC technology opened up our control systems and allowed for lower-cost interfaces between devices," says Don Kaster, senior staff consultant at Boise Inc., a paper manufacturer in St. Helens, Oregon. "This enabled our PC-based controllers to more easily interface with DCS systems, and enabled us to pick our HMI vendor separate from our DCS vendor."

The good news is that there are almost certainly one or more bus technologies that will fit well with your particular application. The bad news is that you must select the right technology, taking care not to pick a soon-to-be-defunct standard. Time promises to improve matters and make selection simpler, as competing standards dwindle to a more manageable few.

About the Author

Leaders relevant to this article: