How to Trust Your Integrator

When we look at the reasons behind a failed industrial system integration project on an industrial machine, it typically wasn’t the control technology that failed. For any given integration project, there are multiple technologies that will do the job. The difference is in the application of the technology. And this comes down to the skills of the integrator and how well the integrator interacts and communicates with the machine builder and the end user. For the machine builder, it is doubly important. Not only must the machine control system perform to expectations, it also must integrate seamlessly into the rest of the end user’s operation.

It’s sometimes difficult to convince OEMs and customers of the importance of integration because they often are focused on the technology. But that’s not the best way to ensure success. Machine builders can improve the chances of a successful installation by using a qualified system integrator for the equipment and recommending one to their customers.

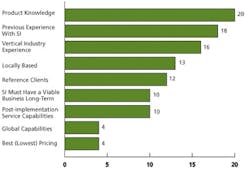

Ranking of System Integrator Selection Criteria

Price and global capabilities aren’t nearly as important as knowledge and relationship history when selecting a sytem integrator, according to a 2005 study.

It’s easy to understand how machine builders might be reluctant to use or recommend a third-party integration service. When a machine builder entrusts the integration of a new factory system to an outside party, it is trusting that party with a critical element of its business. The machine builder understands that a robust and reliable control system is essential to the success of any project. And even if the control system performs flawlessly but doesn’t integrate into the rest of the facility, or is not fully understood and supported by the end user, it still can be regarded as an unsuccessful project.

When a machine builder selects an integrator for its own use or recommends an integrator, it should understand the decision-making process that end users go through when making such a selection. Those who haven’t been involved in integration projects in the past might think that the cost of a job would be one of the top issues on the minds of plant managers.

However, in a 2005 ARC Advisory Group survey of plant owners, plant managers and manufacturing engineers, the price of a job actually ranked last among the top factors that affect the selection of an integrator for a new project. Those factors that affect the likelihood of a project being completed satisfactorily ranked much higher. Product knowledge, the customer’s previous relationship with the integrator and appropriate vertical industry experience ranked as the top three influencing factors.

Machine builders can help their customers to reduce the risk by using and recommending integrators that are certified members of the Control System Integrators Assn.

CSIA’s charter is to set the standard of performance for control system integrators. Approximately 260 member companies and 64 partner companies, typically vendors, are affiliated with the organization. The member companies are integrators of different sizes, but there are minimal requirements in terms of yearly revenue and number of years in business.

Next month, I’ll explain how the CSIA certification process goes a long way toward reassuring a potential user that it’s found a dependable partner. (Read "How to Trust Your Integrator–Part II")

Ed Diehl is executive board chairman of CSIA, as well as co-founder and executive director of Concept Systems in Albany, Ore.