No-Worry Wireless

By Joe Feeley, editor in chief

As complexity increases in manufacturing facilities around the world, the emphasis on improvement sometimes focuses so much on software and advanced controllers it can overlook some basic, but critical mechanical improvement opportunities that evolve from the use of new technology.

In a highly automated production shop in Lippstadt, Germany, automotive parts supplier Hella KGaA Hueck produces front headlamps for luxury vehicles. The company found that a move to wireless connectivity for a key sensing operation greatly reduced process stoppages caused by signal cable failures.

Careful Inspection

In the assembly cell used for this job, the lamp housing first is placed on a transfer slide where a gear system for the headlamp beam adjustment ensures correct alignment. Before a robot mounts the front glass on the housing in the next working step, 12 different sensors interrogate for the correct mounting position of all the individual components. This detailed inspection is a measure to ensure the quality of the headlamps that’s expected by the customers, which are large automotive companies including Audi, BMW, Chrysler and General Motors.

Trailing Cable Causes Problems

Each individual sensor involved in the positioning step requires a signal cable, which is laid in a trailing cable system to the moving transfer slide. Even with careful installation, the rapid and repetitive back-and-forth movements of the transfer slide, typical of many robotic systems, often damage the sensitive signal wires.

“Hardly a week went by,” recalls Andreas Niggenaber, responsible for the machine maintenance, “in which a defective signal cable did not lead to an interruption in production.”

The fault rectification usually began with complicated troubleshooting followed by more time spent to make the repair, which was additionally impaired by the tight space involved.

Apart from damage to or breakage of the cables, other secondary effects also led to problems. “Quite often sensors simply came out of alignment from their proper positions because the rapid movements led to high tensile forces on the connected cables,” explains Niggenaber.

Hella concluded that the only approach that made sense as a permanent solution was to eliminate the signal cabling. The company initiated a project to make the sensor connectivity for the assembly cell wireless.

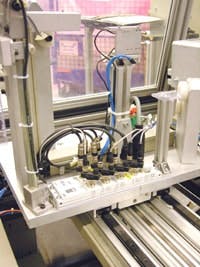

Figure 1: Collection pad

The wireless I/O pad mounted on the moving fixture collects all the signals from sensors that monitor the headlamp assembly and transmits their status wirelessly to a central PLC.

Source: ABB

Wear-Free, Worry-Free

In June 2007, Hella replaced the I/O module on the transfer slide using ABB’s wireless sensor/actuator distributors (Figure 1) with wireless interface for sensors and actuators (WISA) technology. The method eliminates previous interruptions in production due to cable breakages. This radio I/O module has 16 data points, so there remains some expansion reserve for future needs.

“For us it was a clear choice when we saw that the changeover to the new technology could be accomplished without long down times,” remembers Niggenaber. “Therefore, as a preparatory step, the central input/output module that forms the interface between the PLC and up to 13 I/O pads was mounted in the control cabinet (Figure 2) and the corresponding pair of antennae directly on the top surface of the assembly cell.”

In addition, says Niggenaber, the adaptation of the program for the machine controller could be prepared. The programming could be done without the equipment being physically mounted on the machine. The sensors just needed to be in the electromagnetic field. The machine side of the PLC and the input/output module were connected via an ABB Profibus FieldBusPlug. Finally, the IP67 module present on the transfer slide was replaced by the I/O pad and the final commissioning work was carried out.

“Putting the WISA system into operation turned out to be so easy that production operation could be restarted in less than a minute,” says Niggenaber.

In this way the sensitive signal cables could be removed from the trailing cable system completely. Only two 800 FD cables had to be laid for the voltage supply of the transfer slide.

Wireless Reliability

“WISA is the radio technology in the 2.4 GHz band that has been developed by ABB for factory automation and which, through its real-time capability, is characterized by high reliability even when co-located with many systems in a single factory shop,” explains Egon Hillermann, ABB product manager. “The choice of frequency band ensures that communication takes place outside the typical interference spectrum found in industrial environments.

In this regard, there are many mechanisms for ensuring an interference-free, reliable operation that runs automatically without the plant operator being involved. The input/output module and up to 13 wireless pads allocated to it change their communication frequency, continuously according to a specified pattern known as spread-spectrum frequency-hopping. “In this way they exploit the entire 2.4 GHz band,” says Hillermann. “This technique avoids electromagnetic interference of signals from other communication systems, which often leads to functional errors. Communications are terminated only when the opposite end confirms perfect reception. If required, the signal transmission is repeated with a radio transmission cycle lasting just 2.04 msec. Even with a fully expanded system—39 I/O pads each with 16 or 8 data points—this cycle time performance is just as fast as it would be with only a few wireless I/O pads.”

Figure 2: IN-CABINET reception

The WISA input/output module with Profibus fieldbus plug for this application mounts easily in cabinet.

Source: ABB

The wireless I/O pads transmit to the central I/O module twice each second even without a change of status, says Hillermann. “If this signal is missing, the last status information is deemed ‘non-valid’ and sent to the controller, where the production process can be stopped or an alarm signal triggered. In the machine, program specific reactions for fault signals can be programmed individually for each wireless device.”

Easy Commissioning

Machine commissioning with wireless pads is straightforward and easy, says Niggenaber. “Once the I/O module has been switched into config mode, the address selected is assigned to a wireless I/O pad in a non-volatile manner by simply pressing its membrane button. A ‘sign’ function, triggered by key depression, provides unambiguous assignment of the issued addresses in operation. A green LED flashes in the selected pad, while simultaneously showing the address in the display of the central I/O module.”

Additional devices can be added or deleted as described above. If the maximum number of 13 I/O pads per input/output module is not sufficient for the application, an additional device simply is added, including a pair of antennae, says Niggenaber.

Essential Features

Each I/O pad has eight M12 sockets, each doubly assigned—half with two digital inputs, the remainder with two configurable I/Os each. The voltage supply is provided separately for inputs and outputs, each with a current rating of 0.5 A. The supply voltage can be looped through to the next I/O pad. “This avoids additional cabling, particularly when several of these I/O pads are, for example, installed on one larger transfer slide or robot gripper,” says Hillermann.

Fault-Free Future

“The conversion to wireless technology paid for itself in the first months of fault-free operation,” says Niggenaber. “This is because each fault means that personnel have to wait for rectification and production shortfalls might have to be recovered on a Saturday, incurring corresponding additional costs. Added to this are the actual service costs.”

The fault-free operation was so convincing to Hella that a wireless I/O pad has been put on the second transfer slide of this assembly cell instead of the conventional module. In the meantime, WISA devices for the conversion of further assembly cells having the same function have been ordered. “We also will specify this technology in the future when planning this type of assembly equipment—for example for robot applications,” says Niggenaber.

Reliable Power SupplyThe power for the wireless proximity switches and sensor pads in a WISA solution is not supplied by battery but, like the communication, is quasi-supplied by radio. “A WPU100 power supply generates a 120 kHz sinus-shaped signal that carries no information whatsoever,” say Egon Hillermann, ABB product manager. “Using a pair of primary loops, which are attached around the outside of the machine or system like bands, the 120 kHz signal is distributed in the machine as a weak magnetic field.” The wireless proximity switches and sensor pads are equipped, says Hillermann, with ferrite antennae, which are used to collect the operating power from the magnetic field. “Each primary loop has a dimension of 1 m by 1 m up to 3 m by 6 m,” says Hillermann. “This provides a supplied volume of 1 m by 1 m by 1 m, up to 3 m by 3 m by 6 m. Using pointed and linear arrangements of the primary loop, even very localized applications, on a conveyor, for example, can be efficiently operated. The number of the WISA components which can be supplied is, for all intents and purposes, unlimited.” |