Ins and Outs of Modular I/O

By Paul Miller

While many device users and specifiers in our industry consider input/output (I/O) devices to be pretty much of a commodity these days, that’s not always the case. The latest generation of advanced, modular I/O provides the key enabling technology for today’s widely distributed, open multi-vendor automation solutions.

All I/O, regardless of configuration, is modular to a certain degree. So first, we should define the term and determine how modular I/O might differ from conventional rack-mounted or high-density brick I/O.

The Big Three

As most everyone who has used I/O to some degree in the industry knows, there are three main types of I/O. Conventional rack-mounted I/O modules typically plug in to the PLC or DCS backplane and require a separate power supply. Block I/O is a solid brick with a set number of inputs or outputs. Modular I/O comprises a CPU or communications head unit with stackable modules, typically mounted on a DIN rail.

Conventional rack-style I/O usually comes from the same vendors that provide the controllers. This might or might not be the case for brick or modular I/O. Further, while conventional rack-style I/O almost always needs to be mounted inside a cabinet, both block and modular I/O increasingly are available for inside or outside-the-cabinet configurations.

Unlike conventional rack-mounted I/O that only plugs into and communicates with the PLC backplane, modular I/O typically can plug into a number of different industry-standard networks via vendor-provided connectors. Networking standards often allow modular I/O from one vendor to be used with other vendors’ PLCs, DCSs or other computing or control platforms.

In addition to providing basic input and output capabilities for both discrete and analog channels, most modular I/O systems also offer options for onboard discrete control, PID control or motion-control functionality to allow intelligence to be widely distributed throughout an industrial facility.

“Modular I/O allows for fairly granular channel counts and a variety of channel types to be dealt with in a uniform manner,” explains Bruce Thomason, chief technical officer at CyberMetrix, an automation and control solution provider based in Columbus, Ind. “The different modular I/O channel types are hosted with a common interface, using a common bus, physical mounting system, termination provisions and power supply. Modular I/O also allows users to freely change or add channels. Conventional I/O in-chassis or in a larger channel-count brick would not support the changing or adding of channels.”

Thomason says the two differ primarily in flexibility and scalability, with modular I/O winning out on both counts, “unless you just happen to need exactly what the brick has to offer,” he adds. “For us, the beauties of distributed and modular I/O are that it scales up, down and sideways very effectively, with up/down meaning count and sideways meaning the variety of different signals supported. It also allows us to place the right mix of I/O in close proximity to the actuators and sensors we manage.” This, says Thomason, reduces field wiring length requirements, which not only reduces costs, but also reduces EMI-induced noise.

“We use modular I/O in projects across a variety of industries for a number of reasons,” says Matthew Youney of Youney Instrumentation and Control Systems Engineering, an engineering services provider based in West Palm Beach, Fla. “First is expandability. If you run out of slots with conventional rack I/O, you have to add a whole new PLC or at least an expansion backplane. With modular I/O, you just stack it up as you need it.

Modular I/O also offers more granularity so you don’t have to buy stuff that you don’t really need. I also like the small size of most modular I/O. With Wago 750 I/O, for example, a module with eight digital inputs or four analog inputs is just a ½-in. wide. The distributed processing capability of modular I/O via a network reduces field wiring requirements and improves fault-tolerance.”

According to Bob Gardner, product manager, network and interface division, with Turck in Minneapolis, the term “modular I/O” can be a little confusing. “This is because conventional PLC I/O racks are obviously modular, since you can add input and output cards in different combinations for your particular I/O need,” he explains. “That said, the best modular systems available today have a number of features not available with conventional I/O. For example, modular I/O systems can be attached to any number of industrial networks and include power distribution, eliminating the need for many other terminal points in the panel. Modular I/O systems provide I/O in many more counts and varieties than conventional I/O and typically have removable electronic cards, so you can replace the electronics without disturbing the wiring. Modular I/O systems do not rely on a conventional fixed chassis size of four, eight or 16 cards. Instead you can add cards individually, from one to 50 or more.”

The modular I/O concept was developed to fill the void left with conventional I/O, comments Jason Haldeman, product marketing specialist for the Automation Systems Group at Phoenix Contact. “If an application calls for a variation of digital and analog signals, it is difficult to find a vendor that sells a module that contains the exact variation you need,” says Haldeman. “With modular I/O, you create your own custom station by selecting bus interface modules and the exact variation I/O required. If later during installation you realize that you need more or less I/O, you simply add or remove the points.”

Modular I/O can handle a mix of analog, digital and serial more easily. With conventional I/O users often deal with a fixed amount of I/O of one specific type that’s chassis-mount and connected to an accompanying PLC or similar controller.

Source: Opto 22

Rene Gamero and Arun Sinha, engineers at Opto 22 in Temecula, Calif., make the point that modular I/O points or channels typically are not fixed at a certain amount, since they’re designed to be expandable, usually through the addition of new modules (Figure 1). “Modular I/O is also more flexible,” reports Gamero. “With it, you typically have the ability to handle a mix of analog, digital and serial more easily. With conventional I/O, you’re more often dealing with a fixed amount of I/O of one specific type.” Often, this I/O is chassis-type that’s connected to or local to an accompanying PLC or similar controller. “Commonly, this brick of conventional I/O is either all analog or all digital I/O,” adds Sinha. “Expansion is possible but is not accomplished as easily or inexpensively as modular. For instance, to add a single new point of I/O might require you to purchase a whole new brick at quite a hefty cost.”

Ed Rogin, product marketing manger at Siemens Energy and Automation in Alpharetta, Ga., agrees that modular I/O offers a more flexible approach than traditional I/O. “From a user perspective, you can get exactly what you need with modular I/O,” he states. “If you need 10 channels, you can get 10 and not pay for 16. Modular I/O also allows you to add additional functionality such as motor starters or drives that now can be controlled off your I/O systems.”

According to Helge Hornis, manager of intelligent systems at Pepperl+Fuchs, Twinsburg, Ohio, simplicity of design is a big plus for modular I/O. “Conventional I/O typically is located in the PLC rack. This means that sensor input or output cables have to individually run from the sensor to the enclosure, penetrate the enclosure wall and then be terminated on a terminal strip before the leads are finally connected to the contacts on the PLC-based card. Modular I/O blocks typically are mounted directly in the field, and sensor cables are run only a short distance to the module. The I/O blocks then are connected to one another using a network. Only the network cable is brought back to the PLC enclosure.”

When to Go Modular?

Modular I/O is appropriate for use within a broad spectrum of applications but appears to be particularly suitable where a high mix of different signal types or I/O flexibility are required or where it’s advantageous to mount the I/O remotely in the field or right on a process unit or machine.

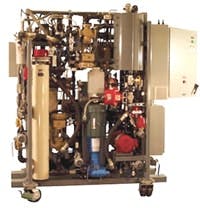

CyberMetrix has semi-customized engineering, in which it integrates its own products and third-party subsystems that sometimes offer only discrete signal interfaces. Modular I/O is very useful for addressing the integration needs.

Source: CyberMetrix

“We provide automation and control solutions, primarily engine and component test lab equipment, for engine and vehicle R&D facilities,” says CyberMetrix’s Thomason (Figure 2). “Our solutions combine semi-customized engineering, our own software and specialized instrumentation, controls and other hardware. In addition to our own core products, we integrate lot of third-party subsystems. When those third-party systems only offer discrete signal interfaces, modular I/O is very useful for addressing the integration needs.”

Thomason says modular I/O really shines when a custom or semi-custom design is involved. “Machine OEMs that offer products with many options might benefit from modular I/O through the ability to populate channels based on options purchased,” he states.

Rugged industrial environments are similar to the shipboard monitoring and control systems Youney builds, which lend themselves well to modular I/O. “You can locate the I/O next to the equipment and then run a single Cat. 5 cable back to the PC, rather than have to run a lot of field wiring through multiple watertight barriers,” he says. “By distributing the processing functions to the remote, networked I/O subsystems, we can enhance overall fault tolerance by limiting the impact of a fault,” adds Youney.

Modular I/O is well-suited to flexible or large work cells where many different I/O configurations are needed, such as automotive assembly lines or packaging machines, adds Brad Woodman, senior controls engineer at the Molex Automation and Electrical Division. “Here, you could have only one part number to handle multiple configurations such as a 16-input module or a mixed 8-input/8-output module or one that’s 16 outputs,” says Woodman. “Only one SKU would be needed, reducing downtime due to stocking of only one part number vs. multiple part numbers.”

Modular and distributed I/O platforms are well-suited for any applications that require a spatial distribution of the I/O, comments Sylvain Olier, product manager at Schneider Electric. “A very compact application such as a small machine might be best with a centralized, in-rack architecture but, as soon as the distance between the controller and the I/O exceeds a few feet, a distributed architecture is better, if not actually required,” says Olier.

For a smaller, distributed architecture, such as what might be found on a complex machine, a simple, cost-effective network such as CANopen or AS-i might be needed, says Schneider Electric product manager Nitin Dhayagude. “For larger applications, such as a water treatment plant, Ethernet is unquestionably the most suitable, because it is by far the most mature, open, scalable and flexible media,” says Dhayagude.

Any Downsides?

While modular I/O offers many distinct benefits, it also presents drawbacks in certain applications. These can include very simple or small applications where a micro PLC might be most cost-effective, or in very high I/O count situations where high-density brick or block I/O might make more cost-sense.

In some cases, it’s a matter of familiarity. “Users might be more familiar with conventional, rack-style I/O,” comments Siemens’ Rogin. “The price-per-point sometimes can be higher in certain high-density or high-count I/O situations when you get more granular. In these cases, you might be better off with one 64-point module, rather than several smaller modules. There are also special cases, often speed-related, for which it might be a better idea to have the I/O mounted right on the PLC backplane.”

CyberMetrix’s Thomason says: “There are not many drawbacks that I’m aware of. Some modular I/O does not scale well to very-high channel-count systems, particularly where the same signal types are employed. Companies like Opto 22 addressed this in a pretty effective way by providing both low channel-count module types with two to four channels/module and also high-density module types with 16 or 32 channels/module in the same modular form factor.”

As with any engineering effort, adds Thomason, good system-level design is necessary where safety risks are present. “Distributed modular I/O has some unique characteristics, such as the potential for only portions of the system being accessible due to power or network outages,” he says. “Some I/O vendors provide built-in functions such as communications-loss watchdogs that can trigger reversion to fail-safe, specification of fail-safe power-up conditions and the ability to do integrity checks. Communications redundancy is also offered in several distributed modular I/O product families or industry bus types. These are not insurmountable problems, just issues to undertake with care.”

Also, while the high granularity and functional distribution characteristics of most modular I/O typically work to enhance fault tolerance by limiting the impact of individual failures, not all modular I/O vendors support I/O redundancy and hot-swap module replacement. Users with mission-critical applications need to exercise particular caution here.

All-Modular Future?

Most experts appear to agree that, for the majority of applications, it’s likely that we’ll be seeing a greater proportion of modular I/O used in the future.

Rack I/O isn’t going away anytime soon, says Siemens’ Rogin. “But I do think that as the competition in modular I/O heats up we’ll see modular I/O become a bigger part of projects,” he predicts. “Worldwide, we’re seeing demand for our modular I/O outpace demand for our rack I/O. This includes many inquiries for outside-the-cabinet I/O that eliminates the need to mount so many boxes and power supplies.”

Molex’s Woodman agrees with the notion that modular I/O will eventually replace conventional rack I/O in most machine control designs. “The current push is to get the I/O out of the cabinet/rack and mount it on the machine, which provides many cost benefits,” he relates. “Modular I/O will be the way of the future since it provides flexibility for the input/output mix for the various applications required by the end user/system integrator.”

Paul Miller was a contributing editor to Industrial Networking at the time he wrote this article. Miller is now senior editor/analyst at ARC Advisory Group.