Handheld OI Aids Security, Safety and Efficiency

Usually, however, it takes two to tango. In other cases, there can be near-lights-out machine user applications for which a machine-dedicated operator interface (OI) is overkill. For machine maintenance or status checking, a bank of machines could be monitored with one portable OI that an operator plugs in at each machine location.

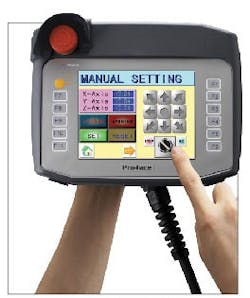

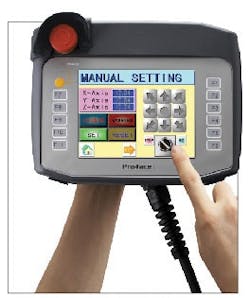

Pro-face America, the North American division of Digital Electronics, has a new product aimed at these applications. The company is expanding its AGP3000 product line with the AGP3000H series of handheld graphical touchscreen operator interfaces.

“System security is a major concern for manufacturing facilities,” says Gary Labadie, Pro-face’s marketing manager. “Pro-face handheld units with a built-in, key-enabled switch limit operation to authorized personnel. In conjunction with enhanced security, the OI also features a log that displays historical machine operations and identifies who made machine parameter changes.”

Machine operator safety works in conjunction with the security features. The three-position, dead-man switch and emergency-stop switch are standard requirements on most handheld units. As an added benefit, says Labadie, the OI is disabled unless the key switch is enabled and the password activating the OI controls has been entered. “With the new unit, machines are more secure, tamperproof and safer to operate, reducing factory floor mishaps,” he adds.

To get the most value out of OI handheld devices, they should include operation conveniences when moved from machine to machine. “The AGP3000H series delivers hot-pluggable quick-disconnect cabling for serial, Ethernet, e-stop and fieldbus communications,” says Labadie. “A compact flash port is provided to load new machine recipes or download logged machine data.” A rugged ergonomic lightweight OI design with natural grip and stylus pen storage location is designed to support simple operation, offer reliability and mobility and increase operator efficiency.

For more information call 734/429-4971, e-mail [email protected] or browse to profaceamerica.com.

“For the factory-floor supervisor, monitoring quality, process yield and overall equipment effectiveness is facilitated by Pro-Server EX data connectivity and reporting software,” says Labadie. “Facilities can integrate machine data and alarms into existing enterprise systems via MES, SQL, DDE, DLL, ODBC or Access. Operational performance is improved by sending the right factory data to the right individuals.”

Pro-face believes the security, safety and efficiency of using a portable OI not only reduces machine costs, but affords opportunities for machine builders to offer enhanced visual machine diagnostics and performance monitoring tool upgrades to their customers on a factory floor machine where an OI doesn’t exist today. “The benefits to the machine builder are reductions of on-site service calls and out-of-office travel costs,” adds Labadie.

The AGP3000H series with user-defined function keys in 6-in., high-resolution TFT or standard-resolution STN and monochrome screen versions will be available August 2008.