Intrinsic Safety Use Shows Some Spark

By Jim Taylor, Venture Development Corp., and Joe Feeley, Editor in Chief

Intrinsic safety is a method used to prevent equipment from causing fires and explosions in areas with hazardous atmospheres, such as explosive gas-air mixtures. Intrinsically safe equipment and wiring is incapable of releasing sufficient electrical or thermal energy to cause ignition of a hazardous atmosphere in its most ignitable concentration. Equipment going into hazardous areas for intrinsically safe applications is classified as either simple or non-simple.

Simple devices have limitations on voltage, current, and energy. These include products such as switches, thermocouples, RTDs, non-inductive potentiometers, and resistors.

Top criteria for selecting hazardous environment protection methods

Simple devices connected to an approved intrinsic safety barrier do not have to be approved as being intrinsically safe. Certification for the design and installation of non-simple devices and equipment is required.

As weve done previously, Industrial Networking worked with Venture Development Corp. (www.vdc-corp.com) to invite readers to participate in a study on worldwide trends in the use of intrinsically safe devices. Users from our system integrator, industrial machine builder, and processing industry end user communities participated in the study. The following are some of the significant research findings.

Wireline Devices and Equipment

By using wireline networks/buses, field devices located in hazardous areas can be connected to controllers outside those areas. Alternatively, wireline networks/buses can connect to distributed/remote I/O located in the hazardous regions that are designed to be intrinsically safe. The field devices then interface with the distributed/remote I/O. Wireline networks/buses used in these applications must limit energy levels to ensure intrinsic safety, and incorporate isolators for this purpose. In addition to the energy-limiting requirements for intrinsically safe networks and buses, critical specifications for such systems include redundancy and a high level of determinism.

The use of wireline intrinsically safe networks/buses allows distributed intelligence in hazardous areas, which provides advantages such as elimination of long, hardwired, point-to-point signal connections; the capability for value-added features such as self-calibration, failure-prediction algorithms and self-generating work orders; and simplification of control system designs.

The use of wireline intrinsic safety is well established as a preferred hazardous protection method in the European/Middle East/Africa (EMEA) region, and the majority (55%) of 2006 worldwide shipments of these products were to this region. For the most part, the remainder was evenly split between shipments to markets in the Americas and Asia-Pacific regions.

Among the three regions, the highest growth rates for all these wireline products are foreseen for the Asia-Pacific region. A large portion of these shipments is projected to go to China and other developing countries in the region where new facility construction is expected to be high. Most of the EMEA market is in Western Europe, where wireline intrinsic safety is well established, and shipment growth expectations are more moderate. However, the growth rate for Eastern European countries is expected to be high as new facility construction there is foreseen to be relatively robust.

Of the three regions, the growth rates of all the products to the Americas are expected to be the lowest. While intrinsic safety is perceived as a better technology with lower operating cost/total cost of ownership, there is little movement in the U.S. toward this technology using wireline equipment and devices. Explosion-proofing still is the preferred and proven method in the U.S. However, light, portable, intrinsically safe wireless devices can address new uses. The explosion-proof protection methodology simply does not apply in this case, leaving more room for greater adoption of intrinsically safe wireless products in the Americas.

The geographic shipment distribution of these wireless, intrinsically safe products is considerably different than the findings for wireline products used in intrinsically safe applications. Of the wireless intrinsically safe devices and equipment studied, 67% of 2006 shipments were to markets in the Americas, 22% to markets in the EMEA region, and 11% to markets in the Asia-Pacific region.

The market for wireless, intrinsically safe products has developed more rapidly in the Americas, following the general trend in adoption of wireless technology in industrial applications. For example, VDC just completed a worldwide study on wireless industrial networking infrastructure products (access points, antennas, bridges, console and device servers, gateways, modems, multiplexers, repeaters, switches, transceivers, and network management software). It found that, of the 2006 worldwide market for these products, about 60% of shipments were to markets in the Americas.

Unlike the market for consumer communication products, the greater early industrial demand for wireless equipment and devices has developed in the Americas, most particularly in the U.S., rather than in other regions of the world. These products hold the potential for improving the efficiency of operations, and reducing costs. Firms with manufacturing operations in the U.S. appear to be under more pressure to reduce costs than elsewhere, and are more receptive to cost reduction measures.

Product Popularity

Intrinsically safe distributed/remote I/O with Profibus interfaces accounted for the vast majority (73%) of worldwide shipments in 2006, and are expected to account for the largest share in 2011. However, the worldwide shipment share is expected to drop significantly to near 50%. The displacement is expected to result from increasing usage of Profinet, other Ethernet buses/networks, and Foundation fieldbus.

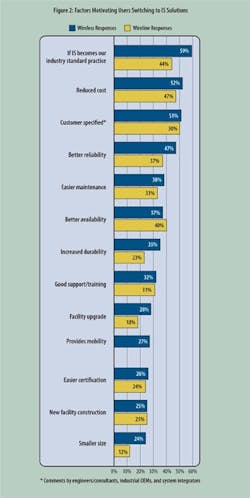

Factors motivating users switching to is solution

HART was the most popular bus/network/protocol by far, accounting for the majority (64%) of shipments in 2006. Foundation fieldbus accounted for the second-largest share in 2006 (9%), and Profibus accounted for the third-largest share (8%).

HART is expected to still account for the largest share in 2011, but that share is expected to erode somewhat, as Foundation fieldbus and Profibus shares are forecast to increase. By 2011, Profinet and other Ethernet buses/networks are expected to account for a small share of shipments.

Wireless Devices and Equipment

The study indicates there is growing awareness of the benefits of wireless data communications for industrial operations, including for hazardous areas. Wireless devices and equipment eliminate wiring that might be impractical or very expensive. Wireless technology also provides mobile communication capability. Personnel using intrinsically safe wireless mobile devices dont have to be at specific terminal ports to communicate with other personnel or with equipment, both in and outside hazardous areas. Mobile communications can enhance safety, increase productivity, and reduce the number of engineers, equipment operators, and maintenance personnel needed.

The largest 2006 worldwide share (65%) of wireless intrinsically safe data communication devices was for products that still use IEEE 802.11b. The study indicates that by 2011, worldwide shipments of products using IEEE 802.11g will account for the largest share (32%), with Bluetooth a close second at 30%. The shipment share for IEEE 802.11b is, not surprisingly, projected to decline.

Bluetooth is popular for these products in some applications because it requires low power, operates over short ranges, has good interference protection due to use of high-frequency hopping with variable hopping sequences, and the cost of providing this networking is low.

In 2006, wireless intrinsically safe monitoring and control components using proprietary networks in several bands accounted for 71% of shipments. Those operating in the 900 MHz band accounted for the largest share (33%). GSM cellular was the only standard network with an appreciable (22%) share. Proprietary networks are projected to still account for the majority of shipments in 2011. Those shipped using proprietary networks in the 900 MHz band are expected to still account for the largest share then, but with a lower share (27%). The largest gain in shipments is expected for products using proprietary networks in the 2.4 GHz range. These are expected to displace GSM Cellular with the second highest market share (25%). The study indicates that IEEE 802.11g will account for a small share (5%) of shipments in 2011.

Two factors should lead to increasing shares for products using proprietary networks in the 2.4 GHz band. First, as the price of components used in 2.4 GHz products continues to decline, market shift to this frequency band should follow. In addition, products using 2.4 GHz can have higher data throughput than lower frequency bands, and can be used in all geographic regions.

The highest shipment growth rates are expected for both of the monitoring and control component categories, with shipments of wireless transmitters forecast at a 35% compound annual grwoth rate (CAGR), and networking products at 26.1%.

Devices and Equipment Consumers

The largest 2006 worldwide shipments of wireline, intrinsically safe, distributed/remote I/O, intrinsic safety barriers and field instruments under study were for the chemical, food and beverage, oil and gas, petrochemical, and pharmaceutical industries. These five segments accounted for between 83% and 93.5% of the worldwide shipments of these products.

The largest 2006 worldwide shipments of wireless intrinsically safe data communication devices and monitoring and control components were for the chemical, oil and gas, petrochemical, and pharmaceutical industries. These four segments accounted for between 83% and 95% of the worldwide shipments.

Hazardous Environment Protection Methods

The study found most users employ a diverse mix of hazardous environment protection methods. The majority of users stated they use explosion/flame proof, intrinsically safe, pressurization and purging, non-incendive, and increased safety measures. More than 25% indicated they use wireless RF/microwave intrinsically safe devices or equipment. Companies do not generally use one particular method to the exclusion of others. They do, however, lean significantly to one method over others.

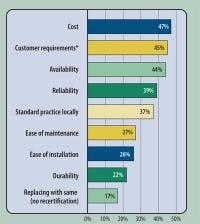

Most important non-product criteria in selection of vendors for is products

Motivation for Intrinsic Safety

The most popular motivators for switching to intrinsically safe solutions among the users surveyed are cost savings and if it becomes a standard practice in our industry. User views on cost savings with intrinsic safety, whether wired or wireless were found to be mixed.

In the current study, other factors frequently identified by users that could lead to their using intrinsic safety instead of some other protection method are better availability, better reliability, easier maintenance, providing mobility, smaller form factor and good support/training/education. (Figure 2)

Criteria for Products/Vendor Selection

Users in the survey were asked to identify the most important features and performance in their selection of wireline products for intrinsically safe applications. For all the product types under study, the most identified selection criterion by far was product reliability. No other selection criterion (accuracy, maintenance, power consumption, etc.) was close.

A large share of users identified product cost among their most important criteria in choosing between hazardous area protection methods. Its not surprising then that price and technical support were among the two most identified non-product-performance selection criteria. The third-highest ranking in this area was availability/delivery, followed by customer service/support. (Figure 3)

For wireless devices and equipment for data communication devices, the most identified criterion was compatibility with existing systems.

Only three other criteria were identified as important by more than 15% of the respondents: the data transfer rate for data communication devices, RF/Microwave transmission certifications for voice communication devices, and use of standard wireless communication protocols for monitoring and control components.

Regarding non-product vendor selection criteria, availability/delivery was most identified, by 83% of the respondents. This was followed by price (67%), technical support (61%) and experience with the supplier (50%). The shares for all the identified selection criteria are larger than those found for the wireline intrinsically safe products, except for customer service/support, which were the same. This indicates a greater concern about these selection criteria among those selecting vendors of the wireless intrinsically safe products than those selecting vendors of wireline products.