Mark-10 Sends STEM to Outer Space

A designer and manufacturer of force and torque measurement instrumentation is working with Tri-County Regional Vocational Technical High School (RVTHS) in Franklin, Mass., and NASA to support student engagement in science, technology, engineering and math (STEM) programs.

Mark-10 donated two Series 7 digital force gauges to students at RVTHS in support of the High School Students United with NASA to Create Hardware (HUNCH) experiment series, recently performed in the NASA Zero Gravity plane.

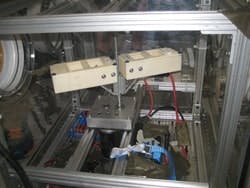

Photo of zero gravity testing apparatus, incorporating the donation of Mark-10 miniature force sensors.

Source: Mark-10

The program was founded in 2003 by Ms. Stacy Hale of NASA Johnson Space Center in an effort to engage U.S. high school students in the creation of creative cost-effective space hardware for training astronauts deploying to the International Space Station. More than 600 U.S. high schools currently participate in HUNCH.

Tri-Country RVTHS students used the Mark-10 force measurement instrumentation to develop a special scale for mass measurements within zero-gravity environments, according to Mark-10. The ultimate goal of the project was to improve an astronaut's ability to better analyze substances in space.

According to Mark-10, "the scale design incorporated the use of a standard fishing scale attached to a spinning platform. By comparing the centripetal force exerted by a known mass attached to the fishing scale as it spins, to the force exerted by an unknown mass, the students were able to compute the ratio of the two measurements to find the unknown mass."

This video illustrates Tri-Country RVTHS students' prototype scale design aboard the NASA Zero Gravity Plane at Ellington Field in Houston, Texas. The students are also looking into a smaller design for use on the International Space Station.