igus Continues Growth Trend After Record Year

Despite a challenging market in 2012, a manufacturer of Energy Chains and polymer plain bearing still managed to increase its turnover by 5%, and break company records.

In 2012, igus served more than 175,000 global customers and sent more than 4,200 shipments on average/day from 13 distribution centers. This year, igus plans for "organic growth" through a long-term investment program, larger capital at new product divisions, and expansion of existing product lines, logistics and production.

"We make three demands on every igus product: Firstly, it has to bring customers commercial and technical benefits, secondly it has to be able to be calculated and configured online, and finally it must be able to be delivered quickly," said Frank Blase, managing director for igus. "Tribo-polymers as our core technology, combined with innovative design and electronics and delivered in no time as standard or special solutions – these are the strengths which make for a good future at igus."

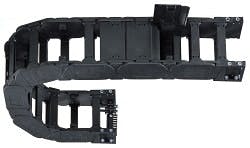

"The Energy Chain system from igus has developed into the most popular type of energy supply system in the world," said Blase. "This underlines the universality and simplicity of the system. Ongoing development is important in the field of plain bearings, too. 14,000 tests in the tribo-polymer development laboratory returned convincing results in 2012."

igus shipped roughly 341,000 pre-harnessed Energy Chains and igus continuous-flex Chainflex cables last year. The company expects additional growth in semi-finished goods, ball bearings, spindle drives, electric actuators and on-site assembly programs, according to igus. New, separate divisions, added staff and more production space will contribute to the foreseen growth. igus has already moved into new facilities in South Korea and Brazil to expand investments in production and logistics.

Product innovation "motion plastics" is a new generation of mico-chains for small, light-weight energy supply applications. The new plastic is 30% less noisy and 100% more stable for larger, non-supported travel lengths. igus has put significant research and development into this product as they suspect it to be a driver for the future.