Robots Make Their Comeback

The number of industrial robots shipped last year almost doubled from 2009, reaching more than 115,000 units worldwide, according to preliminary results from the Industrial Federation of Robotics (IFR). That number is expected to grow an additional 10-15% in 2011, possibly reaching a peak of about 130,000 units sold, according to IFR’s president Åke Lindqvist, who spoke yesterday during a presentation at the Automate show in Chicago.

Robotics sales dipped along with the rest of the world’s economy in 2009, dropping to about 60,000 units, its lowest level since the early 1990s. The 2010 recovery brings numbers back in line with peak years. “The business is back from the good years of 2007 and 2008,” Lindqvist said.

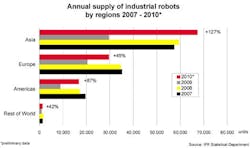

Not every region around the world is equally rosy, however. Asia is dominating growth in the robotics industry, reaching its highest level in recent years with about 67,000 units sold, a year-over-year growth of more than 127%. Korea and China, in particular, performed particularly well in 2010. “Korea has had a remarkable increase—close to triple the level of 2009,” Lindqvist said. “Some additional companies are reporting, but still business is really picking up there.” China is also showing remarkable growth, he said, with 2010 sales up more than 168% over 2009, by far exceeding what were previously the “good years.”

Meanwhile, although Japan’s robotics sales have grown 66%, they are nowhere near the peak years, Lindqvist noted. Europe and the Americas saw growth rates of 45% and 87%, respectively, but have not yet reached the peak levels of 2007.

However, all regions are expected to continue the recovery. The automotive industry is continuing to implement new technologies and use new materials, which will require new manufacturing lines. “High-speed handling and pick-and-place are increasing, especially in the food and pharmaceutical industries,” Lindqvist said. “The level of automation is fairly low still, especially in food, but it is growing very rapidly.”

The merging of technologies is enabling robots to work in food and pharmaceutical environment, according to Kevin Ostby, vice president of Fanuc Robotics America, speaking during a panel discussion that followed Lindqvist’s presentation. “High-speed vision, high-speed line tracking, high-speed robots and communication systems have really assisted implementation of robots in that market space,” Ostby explained.

The growing demand in alternative energy sources, especially following Japan’s recent nuclear catastrophe, will also push robot installations.

Asian markets such as China, Korea, and Southeast Asian countries will continue to driver robot sales increases. “Automotive industry will drive the automation level in China; other industries like plastics, food and electronics are following,” said Kuka Robotics’ Andreas Bauer, chairman of the IFR Industrial Robot Suppliers Group.

IFR expects robot sales to increase further in 2011, at 10-15%. The industry could reach a new peak level of about 130,000 units sold. Moderate annual growth averaging 5% is likely for 2012-2014.