Global CNC Market Will Stay Strong

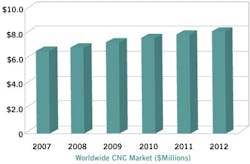

The worldwide market for computer numerical controls (CNC) showed strong growth in 2007 and a positive outlook for the future, according to a recent study by ARC Advisory Group. This illustrates, despite global economic uncertainty, the market for manufacturing and automation remains strong, as Europe and Asia clamor for CNC, says the research firm. The CNC market has exploded in the past two years. The worldwide market for CNC systems, which was $6.1 billion in 2007, is expected to grow at a CAGR of 4.8% over the next five years and is forecasted to surpass $7.7 billion by 2012, according to the study.

The CNC market remains highly consolidated with nearly two-thirds of the market being dominated by Fanuc and Siemens. Competition among the top three suppliers is aggressive, as the developing Asian market ramps up. The issue at stake is installed base; the demand side in this market very rarely switches suppliers due to the investment in personnel training and the ability to move applications from one machine to the next.

Currently, the market is more than halfway through the cycle which experienced its last low point in 2002. The troughs of this cycle tend to be extremely low while the peaks increase slightly from crest to crest. Emerging economies will continue to propel the overall market growth with an unprecedented number of relatively low-valued machine tools built in these regions.

Tougher Than the Times

Despite global economic uncertainty, the market for computer

numerical control systems was more than $6 billion in 2007 and is

expected to flirt with $8 billion by 2012, according to ARC Advisory

Groups latest report.

ARC ADVISORY GROUP