Hoffer Plastics prioritizing hiring veterans

Hoffer Plastics Corporation, a custom injection molding company, has said that it is making hiring and working alongside veterans of the Armed Forces of the United States among its top priorities leading into 2021.

The company has prioritized hiring veterans to fill positions in tooling, maintenance, automation and general manufacturing

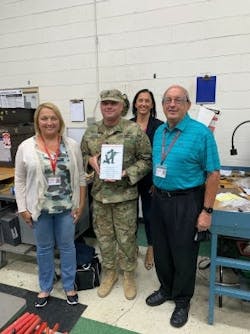

Hoffer Plastics currently employs a group of veterans, including two active army reservists, who have served a combined 43.5 years in the military. Keith Kuhns, an employee at Hoffer Plastics and member of the Marines and the National Guard, was hired on as a mold injection technician. Kuhns applied to become an apprentice in the tool room, requiring three years of classroom experience. Kuhns was deployed to Afghanistan in September 2019; upon his return home, Hoffer worked alongside Kuhns to reintegrate him into his studies.

"I would recommend working for Hoffer to any of my fellow veterans," said Kuhns. "They have continuously demonstrated their support during my time working for them. They sent me care packages, letters, and photos while I was stationed in Afghanistan for eight months. No other company has done something like that for me."