Co-Simulation Sparks Motion Software

It's easy to say that true mechatronics should bring mechanical engineers and their CAD software together with electrical and controls engineers and their ladder and sequential function chart software for machines. It's more difficult to make this collaboration happen in reality.

To help with this, Rockwell Automation spent the past four years working with partner Dassault Systèmes to combine their softwares to enable dynamic simulations that include physical forces and other closer-to-real-time data inputs.

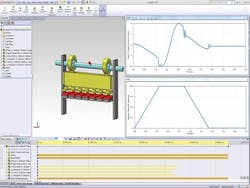

They'd already joined Rockwell Automation's Motion Analyzer software with the Motion Analysis simulation feature in Dassault's SolidWorks software. This link allows the programs to converse in the background, use performance specifications and operations data, and create a "move profile." This gives users a detailed animation—with up to eight axes running at once—to see if their design will move correctly. SolidWorks reports on the torque those axes will need, and this guides users to the motor and drive they'll need. This search can be refined further based on 27 other criteria.

"However, there was one question that wasn't answered by our joint solution," says John Pritchard, global product marketing manager for Rockwell Automation's Kinetix business. "Engineers tuning a servo drive, for example, also want to know, 'What kind of dynamic performance can I achieve, and will my system be stable?' So the next step was to develop a co-simulation feature to show what the real world looks like, and how it's going to affect their design. Many simulations are developed around ideal profiles, but the real world isn't a perfect place, so users need simulations that can handle all the unexpected starts, stops, slowdowns and reverses in real applications."

Consequently, Rockwell Automation plans to launch its tuning simulation co-simulation feature as part of its latest Motion Analyzer 6.0 software. It will be demonstrated Nov. 16-17 at Rockwell Automation Fair 2011 in Chicago, and it's scheduled for release in Spring 2012.

Co-simulation will let users initiate a dialog between the Motion Analyzer tuning simulation engine and SolidWorks by clicking an onscreen setup bar. The dialog is accomplished using application programming interface (API) calls between Motion Analyzer and SolidWorks. Next, the tuning simulation environment will display the interaction between the mechanical system (in SolidWorks) and Rockwell Automation's servo motors, drives, network and controller based on the motion profiles and tuning gains chosen. For example, the co-simulation feature could provide dynamic performance indicators that will show if a machine or system design is stable, and so provide needed throughput at required accuracy.

Besides connecting designs, profiles and controls, the tuning simulation can be used to slow down mechanisms to "human time," and let users see what's happening as they operate. "For example, users will be able to see if system tuning gains are too high, leading to high-frequency oscillation, which is something they might not even be able to see in a real, functioning machine," Pritchard adds.

In addition, the new tuning simulation environment will help develop and deliver machines faster. "This co-simulation doesn't replace the skills of the controls engineers," Pritchard explains. "The difference is that, instead of waiting for a physical machine to be built before it can be tested, many machine builders will now be able to test machines months ahead of time in the comfort of their offices. Earlier testing also means users will be able to adjust tuning, and get to a stable solution sooner. In the past, this kind of dynamic simulation took much longer—to the point that a builder might decide it was quicker to just construct a physical prototype."