Omron partners with AWL for cobot welding solution

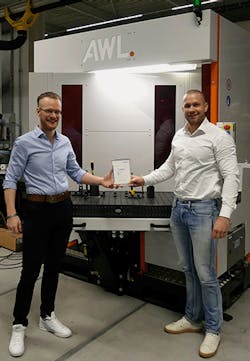

Stephen Pruiksma (right) presents the 'Certified OEM Partnership' plaque to Tom Vrugteveen. Source: Omron and AWL

Omron and AWL have combined forces and entered into a global partnership to develop and distribute a mature cobot welding solution: Qube.

AWL has expertise relating to process improvements and welding, while Omron’s strength lies in automation solutions that support humans and machines. This partnership has resulted in the development of this flexible cobot welding cell, the companies say.

"Up until now there were really only two robot welding methods used in the automation industry: high-end robot welding cells or low-threshold cobots mounted on a pedestal. The robot welding cell is highly suitable for producing large numbers, but for many companies the investment is too high. By contrast, cobots mounted on a pedestal are the best option for smaller series. But what if as producer you fall in this category, and you manufacture series of between 100 and 1,000 units and this series furthermore contains various product types? Or what if you would be able to grow due to the rising demand for products, but you only have a limited number of welding specialists in-house? This is exactly where the challenge lies. AWL has the perfect solution: Qube – a cobot welding cell (ed. collaborative robot)," said Tom Vrugteveen, sales engineer at AWL.

Stephan Pruiksma, manager business development Benelux, innovation manager Omron Benelux added: "With Qube anyone without welding experience can flexibly, efficiently and safely weld, or teach the cobot to weld, in 15 minutes. Using a simple operating panel you can program the cobot in a jiffy, after which production can be started. Furthermore, robots and employees can now work side by side in an efficient way, which never before was possible in the world of welding for safety reasons."