ICS systems bring safety to the start of the machine design process

When safety and control meet, the benefits can include cost reduction and increased productivity. Demand for integrated control and safety (ICS) systems are growing because they provide more safety design upfront, not as an afterthought, and a single programming environment reduces infrastructure, commissioning time and on-going maintenance, and better enables remote monitoring.

ICS systems put safety at the forefront of machine design. “The purpose of having an integrated control system is to be able to implement safety in the network as part of a system, not as an afterthought, but rather as part of the design and the operation of it,” says Michael Warren, product manager of safety components and safety controllers at Omron. “It’s part of the initial design. This serves both a safety purpose, obviously, but it also serves an efficiency process. It works with timing and device response and efficiency of the cell.” Safety design upfront leads to a more efficient process on the back end (Figure 1).

Also read: More open protocols and processing power advance integrated control and safety

A single programming environment can decrease development time, with less software to learn and manage and a smaller learning curve, says K.C. Mangen, product manager of safety sensing at Omron. Safety networks, in general, require less wiring, which is all done through standardized quick disconnect (QD) cables. “Once the devices are on the network, the entire thing becomes more modular, and you’re able to scale it much more easily,” Mangen says.

In the current labor market, technically skilled workers are in demand, and many have different levels of programming experience. “The more intuitive it is, the more integrated it is, the faster the learning curve is,” Warren says.

Figure 2: Fewer components means lower infrastructure costs and maintenance with fewer failure points. (Source: Beckhoff, 2022)

ICS systems give users more visibility into safety issues for faster setup and maintenance. “Too often a black-box safety approach leads to difficult-to-trace faults with little user visibility into the safety system,” says Christopher Woller, safety product manager at Beckhoff Automation. “A single programming environment allows the engineer to easily map state and diagnostic information from any safety hardware or software component to the rest of the larger automation system, allowing for efficient commissioning and troubleshooting.” Distributed safety intelligence throughout the network can lead to faster reaction, when critical, making machines faster and safer, Woller adds.

ICS has infrastructure savings, too (Figure 2). “Reducing the number of components means simpler designs and fewer points of failure. It can also lead to reductions in control cabinet and overall machine footprints, saving valuable space on the production floor,” Woller says.

The initial cost of integrating safety and standard I/O may be more, but the savings in the long run that comes from monitoring and scheduled maintenance, as opposed to reactive maintenance, will save more long term, says Don Leathers, production manager II of automation and control at Digi-Key Electronics.

This also provides speed in commissioning. “Integrating the system needs to start at the time of design,” Leathers adds. “The main function is to improve productivity and user safety, reduce cost and increase the lifecycle of the equipment.”

Figure 3: A single integrator or controls engineer can support both safety and control systems without switching between multiple windows.

Allowing developers to see the machine-process code and safety-system code in one place saves time in development and software maintenance. “Having to switch between windows or having multiple windows open can increase the time spent debugging a program and verifying functionality,” says Noah Greene, product specialist for safety at Phoenix Contact.

A single integrator or controls engineer can support both systems without needing additional training (Figure 3). “It is simpler to connect safety and control systems to move data between the two, so each piece of equipment is on the same page,” says Rudy de Anda, head of strategic alliances at Stratus. “Both safety and control environments are on a single support environment, so it is easier to make upgrades and keep track of when updates need to happen in the product lifecycle.”

An ICS can also enable remote support and troubleshooting. “If a company’s safety system is integrated with control, then many times operators don’t have to spend time troubleshooting an interlocked and shut-down safety system,” says de Anda. And ICS system can also point operators to the first interlock that triggered a fault, as well as the timeline, de Anda adds. “This is crucial to quickly getting operations back up and running,” he says.

Integrating safety and control I/O can reduce architecture costs upfront, but de Anda notes that operators may have to increase the reliability of the I/O, which could add cost overall and in the long run.

With an integrated system, where control won’t conflict with the safety system, this can also bring benefits for testing and commissioning, says Mark Russell, tech application support manager at Allied Electronics & Automation. “If you put them all in one environment, you can see how they're going to react. When you simulate everything, you simulate in one environment, and you can play with the same system,” Russell adds.

The safety system can’t trigger a failure without the PLC acting in tune. The controls and safety systems work in harmony, so that if something fails, it fails in a safe manner, Russell says. For example, the stop may not be quick enough or stop in a bad position. “You have a better way of maintaining the two things together,” Russell says.

The machine design process will include considerably less technology and physical components, Russell says. Fewer network and I/O cables and one computing module means less infrastructure and also fewer points of failure for improved maintenance over the long term.

Figure 4: Industries using ICS are forward-thinking companies, concerned with traceability and Industry 4.0.

Russell recommends ICS for an application that is a relatively low-risk system and relatively simple, meaning a low number of safety zones or low axes of motion—industries such as conveyance and packaging; groundwater and wastewater; and oil and gas.

The industries that are using ICS, in general, are forward-thinking, says Warren of Omron. These industries—food and beverage, logistics, automotive, pharmaceuticals and semiconductors, for example—are concerned with traceability, sustainability, IoT or Industry 4.0 control and integration (Figure 4). “Each of those major industries are required to have traceability from basically cradle to grave of their output,” Warren says. The combination of control and safety makes errors easier to trace, which is vital in high-capacity industries with strict standards for human safety.

A wired relay system may still be the best route for a small system with few requirements. “A large machine will have a much easier time with a safety network,” says Omron’s Mangen. Signal loss over long stretches of wire could be an issue without the network, and many different devices all integrated differently present separate challenges for upgrades or replacement, Mangen adds. “For a large machine, in particular, the safety network should win hands down.”

Integrated safety generally applies best to machines with three or more safety functions or those with distributed I/O and controls, says Woller of Beckhoff. “These include but are not limited to intralogistics, packaging and converting, and pharmaceuticals. However, we have helped implement integrated safety effectively in just about every sector,” Woller says.

Figure 5: Safety over EtherCAT uses the standard EtherCAT network to send safety information with the necessary safety measures. (Source: Beckhoff, 2022)

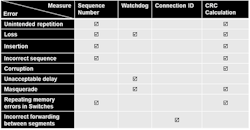

Traditional safety relays and standalone safety controllers may fall short in machines and systems with complex requirements, Woller says. “In these cases, a distributed safety system is more appropriate. Modern safety fieldbuses generally must comply with IEC 61784-3 leveraging a black-channel approach to safety related messages,” Woller says. Safety over EtherCAT (FSoE), for example, uses the standard EtherCAT network to send safety information with the necessary safety measures (Figure 5).

“This integrated approach allows safety controllers, I/O and other safety-related parts of the control system to be scattered across a network yet still maintain an appropriate level of performance,” Woller says.

“We’ve still seen the adoption of highly scalable safety architectures fully integrated into the control system grow exponentially,” he adds. In many cases traditional safety systems aren’t providing the needed functionality for modern automation systems. “As supply-chain issues resolve, this trend toward integrated safety will only accelerate,” Woller says.

About the Author

Anna Townshend

Managing Editor

Anna Townshend has been a writer and journalist for 20 years. Previously, she was the editor of Marina Dock Age and International Dredging Review, until she joined Endeavor Business Media in June 2020. She is the managing editor of Control Design and Plant Services.