Big-ticket transportation vehicles can only take you so far. Superhighways, airplanes and trains eventually give way to local streets and homes. The same is true for industrial networks.

Though many users focus on tying industrial networks up to enterprise and administrative summits, it’s becoming increasingly obvious to engineers that they need to focus downward to the I/O points, sensors, switches, valves and other devices to get the data their managers crave. Unfortunately, upper-crust fieldbuses and Ethernet flavors usually can’t be used with production lines, conveyors, drives, sensors and other device-level settings because their data packets are too big and their networking methods are too complex. They need some way to translate, convert signals and link to these lower-level networks and components, and so upper-level fieldbus users are rediscovering the most basic, seemingly unsophisticated networks and pulling them into the limelight.

This is giving new attention and life to lower-level networks and turning them into 10- and 15-year overnight success stories, even though supporters and many engineers know they were in use—hidden in plain sight—all along. Ironically, taking Ethernet to a plant-floor device requires a dedicated line and maybe another for power, which is similar to the disadvantages of using hardwiring.

Finding Flexibility

Installing and maintaining robot cells is difficult, but engineers at ThyssenKrupp Body Stampings (TKBS, tka-as.thyssenkrupp.com) in Cannock Chase, U.K., found that hardwiring islands of pneumatic valves to a controller was becoming unworkable. “Our roadblock to faster, more flexible production was hardwiring because it made installing new robot cells time-consuming and cumbersome. I couldn’t believe we’d persisted with hardwiring for as long as we did,” says Keith Jones, TKBS’ assembly maintenance manager.

The automotive body parts manufacturer evaluated the major fieldbuses and implemented two-wire-in-one-cable Actuator-Sensor Interface (AS-i) because it could control TKBS’ robots and communicate with its HMIs. TKBS also simplified its wiring by adding Kuhnke’s (kuhnke.co.uk) plug-and-play Airbox electro-pneumatic modules with up to four I/O points to replace the valve island and reconfigure its robots quickly. “If a customer like Toyota, Nissan or Saab launches a new or updated model, we suddenly might have high demand for a particular engine mounting bracket or roof support. As a result, we have to mount our robots and turntables on movable bases, so we easily can relocate and adapt production cells.”

Consequently, AS-i and the Airboxes allow TKBS to have 600 I/O points on its physical-level fieldbus, unlike conventional valve islands. Set up in a bi-stable arrangement, each Airbox is clipped onto the AS-i cable and configured to provide two independently programmable 5/2 input valves and four inputs. This electro-pneumatic system sits on one AS-i cable and regulates 60 robot cells, performing mostly presswork and spot/MIG welding tasks. Each cell has one to four GE Fanuc robot arms operating 24/7. Above this physical layer, TKBS uses Profibus to communicate between the robots and welding equipment, while Profinet provides production data at the control layer. AS-i Safety at Work also allows TKBS to add e-stops to the network and enables it to take on Category 4 safety applications.

Lower-Level Network Implementation To-Do List

|

“Airbox and AS-i mirror our modular design with I/O points easily unhooked and moved as required—just like our robots. As a result, it takes just one month to commission a new work cell, which is a 60% time savings compared to the hardwired valve islands,” says Jones.

In addition, if any part of the AS-i network develops a problem, it can be pinpointed easily. “We moved away from the valve island solution partly because the adapter cables are effectively black holes when it comes to diagnosing a fault,” adds Jones. “Airboxes clipped onto AS-i diagnose themselves. If we have a problem with the new system, it typically can be fixed in 15-29 minutes. Before, six hours was common.”

Getting Down

Similar to all industrial networking, device-level networks grew out of the point-to-point hardwired world. However, while most upper-level fieldbuses adopted open architectures and Ethernet, and gained some presence within the industry’s huge 4-20 mA installed base, most device-level networks still face an even-bigger foundation of legacy hardwiring. Many users might be reluctant to give up their cables because there’s so much more wiring to cling to at the device level.

“You can use a bicycle or an 18-wheeler to bring home a loaf of bread,” says Dave VanGompel, network consultant in Rockwell Automation’s portfolio management architecture and software group. “The truck can do the job, but it’s a lot more costly. You just have to decide what trade-offs you can make. Putting in a large TCP/IP system and coordinating 30 nodes carries more overhead than managing 20 motor starters in a control cabinet with a few sensors.”

Wizardry of AS-i

It’s only a four-bit network, but users and developers report that 15-year-old AS-i’s large and growing popularity is based mainly on its ability to simplify their networks. Flat, two-wire cables carry data and power, don’t need to be enclosed, aren’t hindered by electrical noise and use insulation-displacement to clamp devices onto the network at any point needed.

“The higher-level networks are like interstate highways, but you can’t bring them to every house or device,” says Helge Hornis, Ph.D, manager of Pepperl+Fuchs’ (am.pepperl-fuchs.com) Intelligent Systems Group. “AS-i is like the local streets, but it can form strong bonds with higher-level networks, so builders can design a machine’s I/O structure and pick its control structure at the top.”

Hornis believes Ethernet is driving people to AS-i because, when they look at implementing Ethernet, they have to consider how they’re going to reach the lower level to gather data from their I/O points. “AS-i is ideal for linking to Profinet, EtherNet/IP and Modbus TCP,” says Hornis.

Perhaps AS-i’s biggest milestone since its release is its now-five-year-old AS-i Safety at Work capability , which allows standard and safety functions to run on the same cable. Mike Bryant, executive director of AS-i USA (as-interface.net), says AS-i Safety has fueled a 25% increase in use of AS-i.

Though it debuted with the ability to handle 31 I/O nodes, with four inputs and four outputs each, its present AS-i 3.0 version can handle up to 62 nodes, also with four in and four out each. This latest version reportedly also is simpler to use and has better diagnostics. Consequently, as users developed more and better AS-i devices, the average price for outfitting an I/O point with AS-i dropped, so it’s easier for users to justify implementing it. “Six or seven years ago, the per-I/O point cost for a large user was $20-25 per input or output, but now the cost is only $10-20,” says Hornis. “So, someone who rejected installing a digital network based on cost a few years ago should really look at it again. And, because the price of copper continues to go up, an AS-i network is only about 5% of the cost of hardwire.”

Also, with seven extra 5-msec scans, AS-i can read and gather analog data, which has accelerated its emergence in process applications. “Most of the brewers we work with, such as Coors and Anheuser-Busch, have completely gone from hardwiring to AS-i in the past few years because they can collect the same values, but it’s easier to switch to and troubleshoot, and there are huge wiring savings,” says Bob Jenson, application support engineer at StoneL (stonel.com), a process networking and valve communication supplier. “For instance, delivering three bits of data takes six wires, while AS-i can send eight bits per device or 62 devices per cable back to the PLC, or four, 16-bit analog inputs for a total of 64 bits per device with the added scans. Previously, we had to do analog-to-digital (A/D) converting, which takes a lot more configuration and programming.”

Because of its usefulness and relatively long history, AS-i has been deployed in numerous applications worldwide. For instance, a large roller-bed conveying system at Land Rover’s U.K.-based Solihull plant uses more than 600 AS-i-enabled motor starters and proximity sensors. It saved more than 23% on material and installation costs by using AS-i to reduce control cabling and I/O cards for PLCs, eliminate local disconnects, perform off-site commissioning and speed up diagnostics prior to start-up (Figure 1). Likewise, contract manufacturer Wiewelhove (wiewelhove.de) in Telgte, Germany, operates eight AS-i-based lines, including 20 pneumatic AS-i compact modules and 100 digital modules, to sort up to 6,000 crates per hour of empty beer bottles at Bier Schneider’s (bier-schneider-online.de) plant in Dortmund.

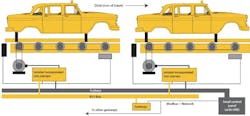

Conveying Cars WITH AS-I

Figure 1: A large roller-bed conveying system at Land Rover’s U.K.-based Solihull plant saved on material and installation costs by using more than 600 AS-i-enabled motor starters and proximity sensors to move, organize and store its car bodies.

Photo by AS-i and schneider electric

Newcomer Networks

Even though AS-i is by far the dominant low-level network, it’s not the only device-level fish in the sea. Even though AS-i’s supporters criticize its two main Asia-based competitors as having little more than specifications, CC-Link/LT and CompoNet also have their supporters, and interest in them appears to be growing as well.

CC-Link/LT (Figure 2) is a bit-oriented spin-off of Control and Communication Link (CC-Link), which was originally developed by Mitsubishi Electric, and is administered by the CC-Link Partner Association (CLPA, cclinkamerica.org). Charles Lucasik, CLPA’s director, says it also uses a flat cable containing communications and power and that it’s designed for use in sensors and actuators. It’s applied in widespread I/O applications with relatively few I/O points, usually 1,000 points in and 1,000 points out or less. Because it’s located in virtual memory, all of CC-Link’s addresses are fixed automatically, which reportedly makes it easier for users to translate node addresses than with other networks.

CC-LINK/LT SIMPLIFIES

Figure 2: CC-Link/LT is located in virtual memory, so all its addresses are fixed automatically, which makes it easier for users to translate node addresses.

Photo by CLPA

“Device-level networks let users add four-point I/O modules, so they won’t have to use up their network’s station/node capacity,” says John Wozniak, PE, CLPA’s senior applications engineer. “Then they can use one 128-bit capacity CC-Link/LT bridge, which can have up to 64 devices on it. As a result, CC-Link/LT can save time, money and space without a lot of unnecessary bells and whistles. To the programmer, these I/O devices look like just another bit in memory on screen, and so they don’t have to worry where they reside. Basically, the network is no longer the bottleneck.”

Likewise, though its DeviceNet protocol long has been used in lower-level applications, ODVA (odva.org) recently launched CompoNet, which is one of five adaptations of the Common Industrial Protocol (CIP). Originally developed by Omron Electronics (omron247.com), CompoNet (Figure 3) uses smaller data packets, so it can be more widely distributed and collect I/O data at high speeds. CompoNet uses a simple 2-bit signal for on/off data, and word slaves, which are I/O points that transmit 16-bit on/off and analog information. Yokogawa, Fuji and Hitachi are developing CompoNet master devices.

HERE COMES COMPONET

Figure 3: CompoNet is a bit-level network that controls small, high-speed devices and supports messaging from the master downward to the device level.

Photo by ODVA

“Omron is committed to CompoNet because using lower-level networks and embedding them on devices means the costs of adding modules to a machine, such as connectors, more discrete components and added housings, are all taken away,” says Jeff Jurs, Omron’s business development manager and ODVA technical review board member. “This is important because manufacturers can use a $12 sensor instead of having to buy a $200 module. It also means sensor and drive vendors can have easier access to technologies and have more of a say in where they go to help their customers.”

Omron claims users are employing CompoNet in various industries, including transportation and carrier systems, electronic parts and automotive parts manufacturing, and building automation and multi-story parking lots. Omron reports that Japan-based Daifuku Co. uses CompoNet in its carrier system conveyors, while SI Seiko Co. uses it to sort fruit and also distinguish them by taste and content. Jurs says one of CompoNet’s key features is that it supports messaging from the master downward to the device level, and that AS-i doesn’t do this yet. Also, CompoNet’s developers have added a low-cost IP20 flat cable and insulation displacement connector (IDC) tap/connector media system, which also was approved for use with DeviceNet in the past year. This allows users to daisy-chain devices.

“CompoNet is new, but it’s a fast, low-level, long-distance network that’s going to be useful for a long time,” says VamGompel. “Ethernet might get down lower and take over some devices in the next 3-5 years, but it’s never going to take over completely. I think the newer networks will succeed because it takes people awhile to appreciate their value and then work them into their applications. Many folks still haven’t gone from hardwired I/O to I/O blocks.”

Future Paths

Low-level networks’ success also is due to the vast installed base of 4-20 mA hardwiring in at least two-thirds of plant-floor networks. This legacy networking pie is so huge that its digital slice can grow comfortably for a long time before competing fieldbuses begin taking market share from each other.

In fact, in the next 12-18 months, Bryant says AS-i’s supporters will begin developing AS-i 4.0, which will include extending AS-i’s network distance beyond 100 m without repeaters and increasing the available power.

“There’s still lots of hardwiring, but PLCs didn’t become dominant overnight, and many still use relay logic,” says Hornis. “No one did digital networking in the past, but there’s lots of it now, and it’s going to be the future.”

Lower-Level Networks at a Glance

|

Actuator Sensor Interface (AS-i) and AS-i Safety at Work (as-interface.net)

CC-Link/LT and CC-Link (cclinkamerica.org)

CompoNet and DeviceNet (odva.org)

|

Leaders relevant to this article: