Part of our OEM Spotlight series —

Engineers focus on making packaging machines more rugged, versatile and simpler to integrate with a wide range of feeding systems and peripheral equipment at Matrix Packaging Machinery in Saukville, Wisconsin. "Our packaging machines are uniquely capable of providing a high level of performance with minimal maintenance and complexity," says Marc Willden, general manager at Matrix Packaging. "Keeping engineering involved ensures we can tailor a wide range of flexible packaging solutions to the specific needs of our customers."

Building a leader

Founded in 1988, Matrix has grown from its humble beginnings in the garage of its founders and is becoming an industry-leading manufacturer of vertical form-fill-seal packaging equipment for all types of flexible packaging. These machines form plastic bags from roll stock, receive product dispensed from above and then seal the product into the finished bag. It has also expanded its product offerings to include horizontal pre-made pouch, stick pack and horizontal form-fill-seal solutions that it distributes in North America.

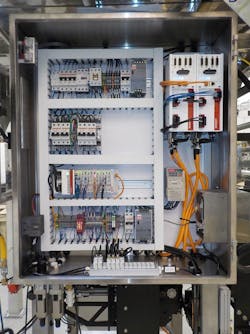

The machine’s PC-based control system provides a low-cost, flexible and expansion-ready system.

Source: Matrix Packaging Machinery

Today Matrix plays a key role in the Flexible Packaging Group of Pro Mach, a leading provider of integrated packaging and processing products and solutions. It acquired Matrix in 2011. Most Matrix systems are utilized in various segments of the food industry.

Matrix has approximately 53 employees, including eight field service technicians and nine engineers and designers. It ships machines worldwide with the majority of its business in North and South America. These machines are supported by a highly experienced service team located throughout the regions.

Also read: Spotlight on Pearson Packaging Systems: It all started with a six-pack

"As an important part of its customer support, Matrix provides a full range of in-house and on-site training, support, installation and after-market repair/retrofit services with 99.9% of repair parts shipped the same day," says Willden. "Matrix also provides Web-based remote monitoring and maintenance hardware and software to ensure maximum uptime and efficiency."

Engineering control

Matrix uses a standardized selection of HMIs, PLCs and PC-based controllers, motor drives and pneumatics depending on equipment complexity. "Matrix control systems are designed for high reliability and flexibility by using appropriate levels of complexity for our machinery and the market place," says Mike Krummey, electrical engineering manager at Matrix Packaging Machinery.

Due to the range of equipment it provides, Matrix Packaging considers all possible features and options in its hardware and software designs. "Standardization of both control hardware and software is essential for problem-free expansion capabilities," says Krummey. "Very seldom is a custom control system needed for even the most unusual application. As such, we don’t offer the choice of PLC, HMI or motor drives."

Matrix Packaging currently uses Rockwell Automation PLCs, but it has machinery designs with Beckhoff Automation PC-based controls that are becoming more common. "We prefer to deliver a rigorously tested and proven solution with a high level of support as compared to customized, brand-specific controls that can be plagued with operational abnormalities and bugs," says Krummey. "It's important to stick with the brands we know, eliminating the complexity and learning curve of different controllers and control hardware."

Connections and flexibility

The current, well-developed, PLC-based design uses serial communication from the HMI to the PLC using standard Rockwell Automation protocols along with ASCII communication strings to and from the temperature control unit. Matrix Packaging's new PC-based design uses EtherCAT for the motion control network.

Matrix Packaging continues its networking with connections to the Internet of Things (IoT), enabled by partnering with Ei3 and its remote monitoring cloud technology. "Ei3 has an excellent product that provides unparalleled firewall protection, which is essential for long-term reliability," says Krummey. "It also allows energy and usage monitoring and remote technician access to the machines. This technology gives us flexibility."

Flexibility of a standardized system allows for control of any possible features and options, and it drives design decisions, continues Krummey. "Careful cost monitoring is also required to continue providing control components that are best-in-class," he says.

Krummey thinks there is a trend toward increased functionality inside of motor drive devices. "Many of these drive units now contain instruction sets that allow for control of entire machines. As this trend continues, we believe that PLCs may only be needed for simple supervisory functions and could possibly be eliminated completely. HMIs are also developing along a similar path, combining into a single controller."