Scalable control system is at the heart of water-treatment process skid

Figure 1: The University of Idaho’s research water-treatment-process trailer provides wastewater treatment via a series of connected reactors and filters.

Source: Nicholas Wood

The University of Idaho is showing some of its creative ways with its N-E-W Tech water treatment demonstration project, which demonstrates innovation at the nutrient, energy and water nexus. N-E-W Tech is a reactive filtration water-treatment technology that uses a metal functionalized biochar as a sacrificial catalyst with ozone for catalytic oxidation. The process purifies water through a series of connected reactors and filters.

The N-E-W Tech water-treatment technology is at the heart of the 40-ft-long, 9-ton research water treatment process trailer that entered wet test trials and system calibration and will include any required redesign (Figure 1). This early-stage development-process trailer and research platform was created to demonstrate the potential of N-E-W Tech as a next generation of water treatment. This large process skid is the Swiss army knife of the N-E-W Tech technology as it demonstrates:

- renewable water reuse

- biomass energy

- water contaminant destruction

- water sterilization

- nutrient removal

- phosphorus recovery

- biochar fertilizer

- carbon sequestration.

N-E-W Tech is our third-generation technology, with its foundation in six issued patents, and it uses patent-pending reactive water filtration with functionalized biochar as a catalyst and ozone for catalytic oxidation. This technology processes dirty water to a level of treatment suitable for reuse and recycling.

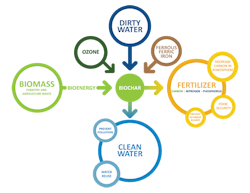

Our N-E-W Tech process trailer will help prove the benefits of this technology including supply of clean, reusable water (Figure 2). In addition, it will also show that the processes’ byproducts can be used for energy production, carbon trading credits and creation of biochar fertilizer. Commercialization of this process is expected in late 2016.

Figure 2: The N-E-W Tech water-treatment process has been cited as one of the 25 innovations that changed the world.

Source: Emily Mower and Nicholas Wood

A look at the science

An important piece of the biomass energy potential of this process is the biochar. Biochar is similar to the activated charcoal often used in water treatment systems, inline water filters and filtered water pitchers. Biochar is a charcoal-like product created from the restricted airflow burning of biomass, such as agricultural waste and wood waste, a process called pyrolysis. Similar to charcoal used in a backyard grill, biochar retains about half of its combustion energy value, as it’s half-burned while produced.

During commercial biochar production, the heat from the biochar process can be used in energy generation, and the gaseous byproducts can be further refined to biofuels and combusted for energy. This biomass energy is “carbon neutral” as it is recovered from plant life and not fossil fuels—an important consideration for green, sustainable energy.

Biochar can also be used in agriculture as it traps and isolates carbon in soils for hundreds or thousands of years, and some scientists consider it a possible solution for climate change. Biochar can also help with retention of water and soil nutrients in the plant root zone for agriculture, ensuring irrigation economy and prevention of nutrient runoff pollution of waterways like the dead zone in the Gulf of Mexico.

Also read: How multidiscipline teams transcend platforms and solve problems

Catalytic oxidation is used for the destructive removal of most organic contaminants in the water. This reaction mineralizes contaminants into carbonates, sterilizing the water by killing all microbial life including prions, viruses and bacterial spores. Bioactive contaminants in dirty waters posing public health risks, such as hormones and antibiotics, can be destructively removed by this process.

The resulting mineralized nutrients, phosphorus and nitrogen, can be recovered from the water by binding to the biochar. The nutrient-laden biochar can then be removed and pelletized for fertilizer use and for use as a soil amendment in agriculture. This is of critical importance since phosphorus recycling is a global food security concern.

Equipment tour

The portable water treatment process trailer was built in about five weeks. It consists of a 40-ft flatbed trailer with a 20-ft metal shipping container mounted to it, and it houses the process controls and instrumentation. The container also encloses valves, pumps, an ozone generator, an air compressor and an air dryer. It houses much of the process piping, along with the sample ports, testing equipment, instrumentation, power supply and control panel.

The major fluid flow systems include chemical dosing, main fluid flow, air and ozone, making this a complete water treatment process research and training platform.

Figure 3: These reactors and filters are part of the reactive filtration water treatment technology, which uses functionalized biochar as a sacrificial catalyst with ozone for catalytic oxidation.

Source: Nicholas Wood

This research platform is designed to not only demonstrate the technology, but to also meet process industry standards since earlier versions of our reactive filtration technology have U.S. and international installations exceeding 10 million gallons per day.

Safety is a primary concern, so we are making this research platform OSHA-compliant in all possible ways as we move forward. Third-party personnel in the plumbing and electrical trades have helped in this regard. Many skilled trade personnel, project engineers and scientists worked long days and endured summer heat in the shipping container to make this process trailer operational.

External to the process control container are twin blue catalytic filter towers and an interlaced pair of lime green plug-flow reactors which perform the treatment (Figure 3). The filters are accessible via a catwalk, and the reactor piping is accessed from the bed of the trailer.

Process steps

The main components of the treatment process include a pair of plug-flow reactors in series. Each of the 45-ft reactors is followed by a corresponding self-cleaning moving bed reactive sand filter. The first reactor introduces low doses of functionalized biochar and ozone. After moving through the first reactor, samples are taken and the effluent moves into the first reactive filter.

This reactive filtration is a priority process in a moving-bed sand filter where the sand surfaces are made highly reactive for removal of trace contaminants. At the exit of the first filter, samples are taken again, and the effluent moves into the second reactor where precise quantities of ozone and metal salts are injected for high-efficiency water polishing.

The injection of ozone coupled with metal salts causes a process known as catalytic oxidation, which provides destructive removal of most organic contaminants by mineralizing them to carbonates, and that also sterilizes the water. Phosphorus and nitrogen, which have bound to the biochar, are recovered from the water reject stream as a byproduct. After a third sample is collected, the effluent moves through the second reactive sand filter where the product water is polished again.

Downstream of the second sand filter, a final sample is collected, and processing is complete. Along the process-treatment train, sensors read out flow, pH, redox, dissolved ozone, head loss, turbidity and total organic carbon. The output of this process is sparkling clear, clean water; and we are actively exploring the efficiency of destructive removal of many trace contaminants and pathogens of concern. We expect publication of our research results in peer-reviewed scientific journals in early 2016.

The mobile platform processes about 15 gal/min, but, because it is based on a commercially proven reactive filtration platform, it is scalable to tens of millions of gallons per day. It’s a high-flow process that removes water contaminants and pathogens in just minutes. Industrial, municipal and agricultural wastewater treatment is anticipated to be a leading application for this technology.

Engineering the technology

I teamed up with Professor Dan Strawn and engineers from the College of Engineering to build this platform and its related control system to further research the intensification and recovery of resources such as phosphorus, energy and water from various wastewater sources using biochar.

The engineering effort was led by systems integration engineer Martin Baker and was part of a capstone effort involving engineering students Tim Hammer, Gene Staggs and a visiting French engineering intern from Suez Environment, Pierre Rasson.

Gene Staggs is a recent graduate from the Bio-Systems Engineering department at the University of Idaho and is the automation and control lead on the project. He contacted AutomationDirect in early June 2015, asking about PLC options to control the project. In addition to the technical criteria, he also explained the accelerated timeline for completion of the project. AutomationDirect technical staff determined its Productivity2000 programmable logic controller (PLC) met the requirements and shipped his entire bill of materials the day he placed the order.

Control technology

Not only is the process technology scalable, so is the control system. The main control panel is located in the process control container and houses the PLC, HMI, power-distribution components, motor starters, stepper drives and local I/O.

The PLC automates all aspects of the process including motor control, opening and closing valves, running pumps, metering biochar and ozone, monitoring flow and level, reading sensor data, process signal control and sampling operations.

Also read: The father of the PLC explains the difference between the PLC and PC-based control

After learning of our design needs, AutomationDirect provided state-of-the-art process control hardware for our project. The supervisory control and data acquisition for the process trailer contains the hardware and comes with wireless data streaming capability. Staggs programmed this unit and integrated advanced digital sensors and controls into the N-E-W Tech process.AutomationDirect supported our design-build goals with advice and advanced technology.

The PLC is AutomationDirect’s most recent addition to the Productivity line of industrial controllers. It provided a modular, rack-based system with a full lineup of discrete, analog and specialty I/O modules to control the process, and the high-performance CPU has the memory and fast scan times needed to control a scaled-up process.

Specifically, the P2-550 CPU was used in this application. The CPU has LED status indicators as well as a four-line-by-10-character, high-resolution OLED diagnostic text display with keypad provides status, configuration, system alarms and user-defined messages. Five onboard communications ports including Ethernet, USB and serial support protocols meet current and future communication requirements.

Data logging, programming, I/O and display

Figure 4: A PLC provides state-of-the-art hardware and software for control and monitoring of the wastewater-treatment process.

Source: Bio-Systems Engineering department at the University of Idaho

Data collection is critical in the process, so significant amounts of information is logged and made available via various means. “Because this is also a research platform, the data logging and network capabilities are invaluable,” notes Staggs.

A micro SD card slot and mating standard micro SD card provide up to 32 GB of data logging capacity for the process. Users can also access the CPU’s built-in Web server via any Web browser to view, download and delete data log files.

“Some of the best features were PID control, custom tag names and QR codes,” explains Staggs. He also reports that the import/export of the tag database was a huge time saver, and he says the team was able to use the spreadsheet-style tag data to help document other parts of the project.

The PLC is running eight separate PID loops and, with auto-tuning, the closed-loop processes were quickly tuned. The easy-to-use programming environment also reduced development time when creating the ladder logic and function block-style programming, and when using the task management feature to structure the program scan.

A wide variety of I/O modules were used in this process (Figure 4). Modules included 16-point ac I/O, a 16-channel analog current input module, an eight-channel analog current output module, a two-channel high speed pulse output module and a four-port serial communication module.

Figure 5: An HMI is used for operator interface and data logging.

Source: Bio-Systems Engineering department at the University of Idaho

Each analog module has a built-in OLED interface to display field signal levels, as well as module and signal faults. All modules include a pull-down QR-coded tab which can be scanned from any smart phone or tablet to get its latest specifications.

The PLC also communicates with an AutomationDirect C-more touch panel HMI via a serial port for operator control and monitoring (Figure 5). AutomationDirect’s C-more EA7 series touchscreen-interface panel was used. It’s an 8-in color TFT NEMA 4/4X, IP65 touch panel with Ethernet and USB ports. This HMI also provides data logging and Web server functionality. The C-more logs data to the USB pen drive, and configured software projects can be loaded to the HMI from its pen drive.

Two AutomationDirect SureStep microstepping drives and stepper motors are also used for preprocessing of the biochar (Figure 6). Commercially available biochar is available in three forms: powdered, slurry and suspension. Our engineers developed a creative approach to manipulate and meter the biochar, regardless of type. Three sets of custom 3D-printed parts were designed to fit on the shaft of the stepper motors.

A simple auger process is used for the powder form of biochar, an auger and a linear actuator is used for the slurry form, and a pair of mixer paddles and a peristaltic pump is used for the suspension form of the biochar. The stepper motors are controlled using a high-speed pulse output card in the PLC rack.

Figure 6: The biochar preprocessing system is one of the most critical as it filters the wastewater and converts byproducts to address carbon sequestration and fertilizer needs.

Source: Bio-Systems Engineering department at the University of Idaho

Process research and training

The mobile platform gives our team a great vehicle to further our research and to show wastewater-treatment operators the benefits of this new technology. While it is still in the early stages of research and development, the results are very promising. Existing studies conclude that reactive filtration is one-third to one-half the capital, maintenance and operation costs of other approaches. And the process will produce useful fertilizer, clean reusable water and even carbon trading credits.

Additional upgrades and modifications are planned for the platform. University of Idaho College of Engineering senior design teams will be considering a number of N-E-W Tech subassembly innovation projects.

With funding from the Idaho Global Entrepreneurial Mission of the Idaho Department of Commerce, the primary function of the mobile platform is to go on-site at various locations such as municipal wastewater treatment plants, dairy lagoons and industrial water impoundments to process effluent, remove phosphorus and collect samples.

The platform is also a STEM education vehicle. The development team has already coordinated tours for elementary, middle-school and high-school teachers and students, and they have plans to take the platform to various professional conferences, as well.

Many recognize that N-E-W Tech is an ambitious research undertaking with a focus on the future. We have dozens of basic and applied research questions still to be answered in our work, and many engineering subsystems still need to be worked out using advanced material handling and process control approaches. We are optimistic for success but recognize the considerable trials ahead as we address the grand challenges at the nutrient-energy-water nexus.

Gregory Möller, PhD, is professor of environmental chemistry and toxicology at University of Idaho-Washington State University (UI-WSU), School of Food Science, Environmental Sciences Program. His award-winning open webcast course, “Principles of Sustainability, with lectures filmed as documentaries in HD surround sound, has global distribution including a June 2015 SatTV broadcast across the continent of Africa on the People’s Weather Channel.

He was the 2014 recipient of the National Excellence in College and University Teaching Award, sponsored by the U.S. Department of Agriculture and the Association of Public and Land-grantUniversities, representing 238 public research universities, land-grant institutions and state university systems. Internationally, he was recognized in 2005 as a fellow of the International Union of Pure and Applied Chemistry for efforts in toxicology education, and he received a 2005 Teaching-Research Fulbright Scholar Fellowship in Greece at the University of the Aegean in Mytilini, Lesbos.

Professor Möller’s research is in the field of environmental and food-chain contamination, and in the development of sustainable water treatment processes. He has worked with students and collaborators to advance the goals of sustainability by developing new knowledge and innovations in the area of sustainable solutions for water resources, with positive impacts on individuals, communities and the environment, nationally and internationally. He has had six U.S. patents issued and licensed in the past six years and has two patents pending for new approaches to sustainable municipal and industrial water treatment. These new technologies have met with commercial success across the United States and abroad.

The Water Environment Federation, with 36,000 individual members across the globe, awarded the Harrison Prescott Eddy Research Medal to his team. The Association of University Technology Managers cited his team’s water treatment technology as one of “25 Innovations That Changed the World,” alongside the Google search engine. The Science Coalition selected his team’s water treatment research as one of 15 national examples of how Americans can benefit from their investment in university research through scientific advances. About 3 million people across the globe now have reduced impact on water resources because of these innovations.

Leaders relevant to this article: