Figure 1: CompactRIO controllers, PCs or PLCs are considered the master controllers that must communicate to many different types of slave devices. Getting the slaves to talk to the master is the challenge of integration.

Programmable logic controllers (PLCs) have remained the industrial controller of choice among control, automation and design engineers. PLCs are often referred to as the master controller that sequences the main logic and manages network data on automated equipment. They’re considered the hidden workforce that silently executes ladder-logic instructions behind a closed electrical cabinet door. PLCs, however, are generally not installed or integrated alone on automated machines.

Third-party products, such as servo motors, vision systems, testing equipment or robotics, are often used to complement a PLC. These complementary devices are referred to as the slave components that work in harmony with the automated systems and are controlled by the PLC in a master/slave relationship (Figure 1).

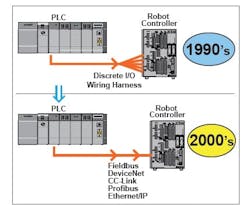

Conceptually, integration of third-party devices consists of discrete-wiring I/O to handshake signals between the PLC and third-party controllers (Figure 2). As technology evolved, fieldbus became the integration method of choice for connectivity and sharing of memory mappings between a master PLC and its slave devices.

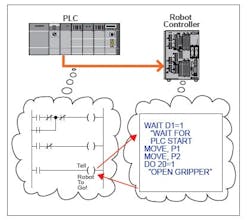

Even at this level, the concept of data exchange happens in a manner where each device is treated individually or managed separately using each device’s configuration or programming software. PLCs have a programming software suite that must be learned by an engineer, along with other third-party software to program and configure a slave device that will connect to the master PLC. The old-school method of integrating the master and slave devices has been the de facto standard in industrial automation. This entails an engineer writing code in the third-party device and writing ladder logic in the PLC manufacturing software. The software code then has to interact with each other, often referred to as “software handshaking.”

Figure 2: Over the years, integration styles have changed from discrete wiring to fieldbus hardware. Fieldbus has allowed for a streamlined connection between two different devices.

Writing custom handshaking software between multiple devices has been cumbersome over the years. When an engineer wants to integrate another third-party device, the whole process of writing custom code must be thought through and debugged. Most engineers have this thought process engrained in their minds on how to sequence and interlock separate controllers, becoming somewhat of a standard mindset.

The pain level of integration

The problem with this old method of integration is that it’s a point of pain for engineers as they must continually learn a new third-party software package or attend a vendor training seminar to properly write software for the third-party devices. In an industry that demands a great deal of time from a custom machine integrator, engineers simply don’t have time to learn about a new third-party device. This is a large deterrent for potential first-time users. They’re reluctant to try new vendors because of the learning curve involved in understanding how the slave device integrates and communicates with the existing PLC system that’s designed into an automated machine as the main controller. This pain level creates additional costs in a project scope as engineers are forced to learn new software devices, directly impacting engineering time quoted on a project.

Over the past decade, fieldbus has advanced in sharing software memory mappings between the master PLC and third-party slaves. Today, the logic concept still stands that the master PLC is written to sequence the main control on the automated machines as the third-party slave devices have code written in a non-standard ladder logic format. This is, however, dependent on which kind of a device is handling the auxiliary process. In some cases, third-party devices are written in structured-text language sets that must be treated as a stand-alone process. These software subsystems must be written to act independently of the main PLC architecture. Therefore, the pain level of learning comes into effect, as engineers must learn how to write code in these third-party devices that are often not coded in the same way as the main PLC ladder-logic standards.

This exchange of information is generally a single bit level flag that is set in the main PLC from a ladder diagram rung, which instructs the slave devices to go or start the auxiliary process. At this time, the ladder sequence in the PLC must wait for a confirmation bit from the third-party device indicating its process is complete. This is a low level of data exchange, and extracted information is vague once its task is complete. As automation and technology have evolved, the need to share detailed information about third-party process controls has become more demanding in terms of preventing failures or logging statistical data about a part in production. Because of simple mapping concepts of the bit-level exchanges, it can be difficult to extract the scientific data of actual results from third-party processes to and from a PLC’s memory mapping exchange only.

New concepts of robotic control

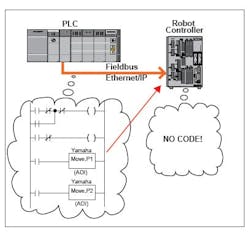

How do you change the mindset regarding third-party control? With a robot controller, what if there were a way to embed direct control of third-party devices into PLC ladder logic? This type of control methodology would be a different concept or approach in a control scheme. By creating function blocks that communicate with the robot controller directly in ladder logic, it simplifies the integration handshaking between multiple devices such as a PLC and a third-party controller. If you could simply make the robot move with a single ladder-logic function block, this would solve all the issues of integration and eliminate the frustrations of learning another software package.

Allen-Bradley PLCs from Rockwell Automation have provided the ability to create control function blocks called add-on instructions (AOIs), which allow third-party vendors to create control or function blocks that are imported into the PLC. However, not all AOIs are created equally. Some AOIs have been created that try to emulate the old-school integration concept. These can make it easier to interact and integrate with a robot controller, but code still has to be written in the robot controller before the robot is instructed to move via the PLC. How can vendor-provided AOIs take the integration to the next level?

Figure 3: By moving the sequence control into the PLC ladder logic, the robot software portion is eliminated.

This is done by changing the concept of that interaction to something that simplifies the control of a robot where the PLC commands the robot directly without the need to learn or write a single line of code in the robot controller. It would be a significant improvement to provide PLC programmers the ability to directly control their robots in an integrated manner within the PLC software and sequence direct robot motion from within a ladder-logic instruction block. This is exactly the approach that we’ve taken with our RCX240 controller connected via Ethernet/IP to an Allen-Bradley PLC (Figure 3).

AOI Blocks

Figure 4: This example shows software integration of two different styles of software development. The PLC on the left is written in ladder logic, while the robot controller on the right is written in structured text language.

In our controller, special firmware accepts command codes from the PLC ladder-logic AOI blocks. It commands a Yamaha robot to move in the same manner as if a robot programmer wrote Yamaha code using structured text scripting (Figure 4). Specially designed AOIs can create and generate the command code automatically that the RCX240 controller understands and interprets. These commands are turned into instantaneous robot actions.

The AOI blocks are designed to send information that break down sequence control to an upper level code that behaves like an application programming interface (API). AOIs receive programmer parameters that direct the robot to move, change parameter settings or send information to the PLC when requested. For example, if a PLC ladder AOI block was executed in ladder logic, this block receives direct Cartesian millimeter values in the form of x, y, z and r values, along with a speed parameter (Figure 5). When the ladder-logic block goes true, only these parameters are sent to the robot controller, which then processes this information to handle the motion command and moves the robot from where it is to the newly instructed position in 3D space. By controlling the sequencing in ladder logic, the PLC programmer can move the robot around in the work cell with AOI blocks.

Typically, a fieldbus communication protocol is used to exchange information between the robot controller and the PLC. In the case of the Allen-Bradley device, the fieldbus protocol of choice is EtherNet/IP. Other fieldbus options can be used such as Profibus with Siemens and GE PLCs or CC-Link with Mitsubishi PLCs. The exchange of I/O memory mappings between the two devices is communicated via special block registers that the robot responds to when certain hex commands are received that are embedded within the Yamaha controller’s firmware code. The robot controller listens to these registers and reacts instantly when certain codes are received in the proper sequence. This sequence is managed by the custom AOI blocks that the engineer imports into the PLC project.

For example, traditionally a robot or servo-motor position is taught via a vendor software package using a method of jogging a robot and teaching its location to a point map memory area. These points are then recalled via a vendor software programming language to sequence a robot step-by-step in an automated work cell. With AOIs, an engineer can elect to teach points via the teach pendant and sequence the robot movement in PLC ladder logic as one option. Another option is to create a user-defined memory type (UDT) in a tag-based PLC that records and stores the Cartesian dimensions of the robot or servo motors in the PLC memory area. With direct access to the point data in the PLC, the engineer can use any preexisting ladder logic to manipulate or command the robots to any point without having to store the robot’s positional data in the robot controller. This provides the ability for special machine builders or engineers to design elaborate or control-savvy interfaces for their machines with the ability to manipulate data directly in the PLC for robot position and robot sequence control.

AOIs are developed natively in a PLC programming software environment. In the case of Allen-Bradley devices, AOIs are created as add-on-instructions that appear as additional function blocks in RSLogix 5000 software. The engineer uses the built-in feature of the PLC programming environment to drag and drop instruction blocks from the toolbar directly into ladder logic as if the robot toolset were part of the PLC software suite. The concept of robot control via ladder logic can be used in any PLC software that provides the ability to create custom function blocks. Other examples include Simatic Step 7 software for Siemens or Sysmac software for Omron.

Benefits

Figure 5: This AOI block is part of the ladder logic that can control an RCX240 controller directly by passing in Cartesian millimeter parameters in the form of x, y, z and r dimensions in a 3D space, which will directly influence the robot to move the end-of-arm tooling from where the robot has traveled to the new destination position via its own trajectory calculations.

Benefits identified with new control philosophies include no additional training, no additional robot software required to learn, development software cost savings and ease of integration between multiple third-party devices.

No additional training is required for maintenance or engineering staff. Instead of learning another vendor software package, the method of robot control is using ladder logic. A majority of maintenance staff and engineering personnel are usually already versed in PLC ladder logic. They are comfortable using a PLC or ladder logic in their own facilities. They feel confident using it in automated applications and are competent enough to write or edit software using ladder logic over a structure text or robot programming environment.

Development cost for integrating a robot is reduced by as much as 40%. This number is an average of data collected by early adopters of programming the robot sequence all in ladder logic. Robots programmed in all ladder logic reduces software integration time as there is no additional learning curve or requirement to write traditional PLC ladder logic to interlock the robot sequence within the PLC sequence. Since the robot can be controlled in the PLC entirely, there is not any integration of a separate robot controller. The robot controller only needs to be supplied power and a common Cat. 5 cable that exchanges data via a fieldbus protocol such as Ethernet/IP.

Expected performance

Controlling a third-party device is limited via the fieldbus performance cyclic cycle and PLC scan times. With Ethernet/IP, typically a request for packet interval (RPI) is 10 ms for each slave device attached to the master. If a PLC is commanding a motion control device over fieldbus, an expected performance can be derived from the following:

Bus Time + PLC Scan Time + Slave Device Response = Total Expected Response.

These performance levels may vary depending on several variables; however, with Allen-Bradley and EtherNet/IP, the command response between a standard CompactLogix PLC and a Yamaha RCX240 controller is about 20-30 ms. Controllers that are strictly designed for motion, such as robot controllers generally have a typical scan and execution time of 2-3 ms to execute a motion command from a written structured text program in comparison to the command of motion sent from a ladder logic PLC arriving in about 20-30 ms.

Conclusion

Providing a new method to write sequence logic inside the PLC as ladder logic provides flexibility to the automation software engineers. Harnessing a powerful platform that controls factory automation and coexists in the same development platform allows for ease of information exchanged between multiple controller platforms. Developing in the ladder logic software environment reduces training required for personnel to learn additional software languages. Most engineers and technicians that maintain automated equipment already have a basic understanding of sequencing automation software in a ladder-logic environment.

By reducing the amount of training required, this saves training costs to companies who embrace new control mythologies. Writing ladder logic sequence for motion control is not uncommon, as Rockwell Automation has provided Kinetix Integrated Motion architecture that utilizes the same typical motion function blocks to move servo motors on an automated machine. Bringing a SCARA robot or 360° zero-blind-spot robot into the mix lends itself to easier integration options for smaller robotic actuators when designing a custom machine.

Leaders relevant to this article: