Automation in Agriculture—how FireFly's turf harvesting machine ups productivity

Bringing a high-end control system, programming and mechanical design to FireFly's automated turf harvesting machine proves technology and automation work well in agriculture applications. Not only is the FireFly ProSlab 155 more efficient and productive compared to what was originally available in industry, it also connects to the Internet of Things (IoT) to bring even more technology to the field (Figure 1).

Things started slowly but moved quickly for FireFly in North Salt Lake, Utah. "We started in business in 2010 building aftermarket parts for the turf farming industry," says Steve Aposhian, CTO and president at FireFly Equipment. "Having grown up on a farm and with my brothers identifying problems with existing harvesting equipment, we designed in some improvements. Feedback from customers in the industry triggered the design of the ProSlab 155 machine." FireFly made the leap of using advanced controls to solved a number of problems customers were facing in the industry.

Aposhian is a mechanical engineer with an emphasis in software development and controls design. Using engineering knowledge, the FireFly team observed that there were machines out there dedicated to cutting flat slabs of turf that worked under some conditions. However, the machines weren't very productive; they were slow and had reliability issues requiring high maintenance. The existing turf machines were also not very flexible.

Figure 1: FireFly combined technology with a design based on customer needs to the field of turf harvesting.

Source: FireFly

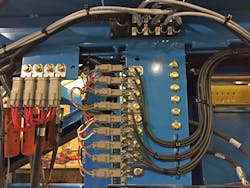

Figure 2: An advanced control platform was one of the keys to improved efficiency and productivity.

Source: FireFly

There are a wide range of conditions in the field. "Sod is perishable and is grown all over the country and close to most metropolitan areas, so there are different soils and different grass types," says Aposhian. "The industry needed a machine that worked in a wide variety of field conditions."

Instead of a turf harvesting system based on hydraulic activation and simplistic control algorithms, a higher level of control was needed, continues Aposhian. "Looking at the needs of the industry, we determined the use of advanced controls, including servo systems, was the solution, even though it is not normally done on mobile equipment,” he says (Figure 2).

A new design begins

FireFly started the design of a high-performance servo motor control system for its turf stacker movements, which addressed two needs of the market—neatness and durability. "The precision motion of our machine made it easy to create neat pallet stacks," says Aposhian. "It also helped durability when the system was sped up. When original manufacturers tried to speed up, the result was rough, moving mechanisms that didn't place the turf accurately in a stack. This rough, jerky motion also tended to tear up the turf square. The servo motion provided excellent positioning capability and speed and was gentle with the turf due to the smooth velocity control. This smooth control also helped the durability of the equipment that could see millions of cycles a year."

That's a lot of 450-sq-foot pallets—a common size—that can be stacked in a little over 2 minutes.

Another benefit of the servo control is it is much more fuel efficient, says Aposhian. "Taking a look at the industry and with the team’s background in other areas of automation, we saw the opportunity to bring a higher level of control design to an industry that really needed it," he says.

The first machine

"We started design in 2010 on a part-time basis and went to full-time design with me and three other engineers in June 2011," notes Aposhian. "We completed the design and build of the first machine and brought it to a trade show in April 2012. There were a lot of long hours in completing it in less than a year."

Also read: Scalable control system is at the heart of water-treatment process skid

Aposhian focused on the software, electrical and hydraulics, and three other engineers focused on the mechanical and motion during this rapid development cycle. Six machines were built, and then a revision created an improved model as part of the development cycle, and more machines were built during the first year.

The control system helped speed the development cycle. "Part of the testament to the National Instruments platform used is that it allowed us a rapid development cycle when implementing some fairly sophisticated controls," says Aposhian. "Having a strong background with National Instruments helped with the choice of the control system, but there where many reasons. I had been doing LabView for 14 years, but, more importantly, the LabView CompactRIO platform was ideally suited for the requirements we were faced with. The turf machine is really a collection of small machines all on one piece of equipment."

An up-close look

In the front, the machine cuts and singulates the sod (Figure 3). The cutter extricates the grass from the ground consisting of two different processes. One process controls the blade that cuts underneath the grass—the skim cut—and one that cuts vertically to cut the piece to length similar to a flying cutoff process. These cutting mechanisms feed the conveyor, which delivers and positions the turf for the stacker to grab.

Figure 3: The turf cut depth, length and delivery conveyor are just a few of the many systems that make up the turf-harvesting machine.

Source: FireFly

The turf is positioned at the high-speed stacker using encoders on the conveyors and photo-eyes to register the position and coordinate pickup with the servo-controlled stacker mechanism. This provides some buffering, and the turf can be picked up on the fly without stopping the conveyor.

The stacker has the servo motion control hardware to pick the pieces off the conveyor, move them to the pallet and stack them. This is a very high-speed and high-performance pick and place. At the pallet, there are forks and an empty magazine system for up to 20 pallets. The forks and magazine work in tandem, lowering the pallet incrementally as the turf is stacked and then placing a completed pallet on the field.

The tractor itself is another major system including the drive system, propulsion and steering that the control system can monitor and control. This self-propelled tractor moves all the automated systems through the field.

Control coordination

All of the systems must work in parallel since this is a continuous flow operation. "While the stacker is stacking, the cutter in front cannot stop cutting," says Aposhian. "The LabView CompactRIO is well-suited in handling these parallel systems, simultaneously. It also enables very rich transfer of data between each system. There is significant coordination between each parallel system, where synchronizing conveyor speed with tractor propulsion speed is one of many examples."

Creating parallel control loops in the same software program enabled excellent coordination of the individual processes, continues Aposhian. "The LabView CompactRIO showed great capability in controlling both high-speed and medium-speed asynchronous processes and bringing them together into one unified system," he says.

The turf machine has both hydraulically and electrically controlled motion. It's a mixture depending on the system. The conveyors, pallet forks and pallet magazine system are hydraulically controlled. The high-speed stacker x, y, z and rotate axes are all servo-controlled using Kollmorgen AKD drives and motors. The cutter combines hydraulic and electric servo control—the cut depth is hydraulic and turf cut-to-length axis is servo for turf length accuracy.

"Electric servos are used where high-speed and high-accuracy position control is needed," says Aposhian. "Hydraulic is used where high power density is needed without the need for accurate position control. The pallet forks are a good example. The forks are very similar to a fork truck where a simple valve and cylinder do a lot of work with reasonable speed and accuracy."

The wide variety of actuators on the turf machine include five axes of servo control and more than 30 hydraulic valves tied to motors or actuators, continues Aposhian. "There is the balance of cost when selecting servo electric or hydraulic," he says. "The hydraulic valve and motor are a fairly inexpensive system compared to a servo axis. It's cost versus performance. Overall there are more than 30 feedback control loops on the machine. These control the blade, conveyors, hydraulic valves, speed control valves and proportional valves."

Sensing the turf

The sensors use similar cost vs. performance decisions. "We use two different CAN buses for sensors, as well as discrete and analog sensors," says Aposhian. "Overall the machine uses almost 80 digital and analog sensors and approximately 100 digital outputs (Figure 4). There are a variety of other analog sensors on the machine including Hall effect sensors on the joystick and a load cell to measure the weight of the pallet. There are also hydraulic pressure and temperature sensors monitoring the hydraulic oil. All critical systems are monitored."

Figure 4: Photo-eyes, pressure, temperature and valves are just some of the nearly 200 inputs and outputs on the machine.

Source: FireFly

One of the CAN buses connects to J1939 devices, such as a keypad, and is an in-vehicle bus common in trucks and off-road vehicles used in agriculture. A CANopen network is used for time-critical devices such as encoders. Aposhian says it depends on the system, and all the sensing methods fit easily into the LabView CompactRIO.

Encoders are used on conveyors for position and speed control, and there is a roller on the front of the machine that measures the turf for closed loop cut-to-length control. Steering can also be closed-loop-controlled. Although the operator has manual control of the tractor steering, the machine can also follow the edge of the grass that was already cut.

The machine uses a steering shoe that is spring-held to the edge of the previous cut. An encoder senses the position of the shoe and thus the edge to control the cut width and position. There is little need for the operator to steer the machine during much of the cut process since the edge position is fed to a steering control algorithm.

When selecting the encoders for the turf-harvesting machines, FireFly needed to find equipment that could operate reliably under the hot, dirty and damp conditions typically encountered during the turf-harvesting operation. The machine is also periodically cleaned with a pressure wash system—a concern for all sensors and actuators.

FireFly uses Posital IXArc absolute magnetic encoders with an environmental protection levels up to IP68/IP69K. The available CANopen electronic interfaces simplified integration of these encoders with the LabView CompactRIO while the relatively compact form factor made them easy to fit into the machine.

HMI, setup and safety

The cut depth is controlled using an electric mini-actuator that adjusts the position of the blade relative to the roller on the ground. The operator has control over a variety of cut parameters and uses an HMI to adjust them. In the seat, there is also a joystick and keypad for greater control such as starting and stopping the cutter, lifting the cutter head and other functions where it is not necessary to touch the HMI screen. All of these devices are inputs to the LabView CompactRIO controller.

Some grasses are grown from seed; some grows back from the roots; and some grasses are grown from a strip of grass remaining in the field after harvest, called a ribbon. It's all dependent on the grass variety. The turf machine can harvest any grass. It's just a quick operator adjustment for cut depth, ribbon width or to do a clean cut.

A lot of safety is designed into the machine, notes Aposhian. "There are three emergency-stop pushbuttons on the machine that stop motion, disable valves and remove hydraulic power when activated," he says. "The safety system is designed as a redundant, control reliable system. The main disconnect is simply the operator turning off the engine, as both power and electric are generated there."

Figure 5: The environment can be harsh and rugged where the sensors, valves, motors, conveyors and actuators must operate.

Source: FireFly

The machine also includes remote diagnostics. "We do a couple of different things with remote diagnostics," notes Aposhian. "Each machine is capable of connecting to the Internet, and a secure VPN network is used to connect to each machine. With the connection, we can perform software updates and advanced diagnostics not available on the HMI. We are also exploring condition monitoring. As we build this historical data, we will push out recommended service intervals for the various systems on the machine. As part of the machine learning process, we need to collect the data before it can be analyzed and used from a maintenance standpoint."

Cutting the grass

Results and performance of the equipment has been very good. "We have received great response from the industry and sales are increasing," says Aposhian. "It's exciting for us to know that we have a platform that is capable of much more as we continue to develop the machine."

A good example is, a couple months ago, a new software update gave customers 5% more productivity, continues Aposhian. "The base control-system platform and mechanics of the machine are so capable, we will be able to offer advances, and customers will continue to see improvements in the machine," he says. "It's not just machine control improvements, this will also include benefits from the Internet of Things and related improvements to the customers' logistics. There is a lot of potential."

Even though FireFly has a background in the sod industry, its strength is a team approach to making a machine like this. "It was really a marriage of software, electronics, electrical, hydraulic and mechanical design to make the mechatronic system," says Aposhian.

"We are really good at bringing the different disciplines together. With the technology and our cross-discipline team and the ability to design and implement the machine, there are many related areas we can explore. It's exciting for us. The sod and turf grass industry has unique needs. It's not a giant industry, but there is more to do out there. The next machine is probably a variation—sod in rolls and other sod production equipment. In the long term, we are an automation company, specifically focused in the agriculture world (Figure 5)."