A Control Design reader asks: I work for an OEM, and we are developing new equipment that requires multiple motion applications on one machine. This includes master-follower rollers, tension control, unwind, wind, variable speed conveyors, a precision three-axis gantry and automatic changeover position adjustments. It covers the full range of motion control from simple ac induction motors to stepper motors and precision servo control.

Our sales department wants to sell this new OEM equipment as the latest technology including the buzzwords "precision motion” and “IoT-ready features.” With all the different motion-control requirements on the equipment, do I mix and match the best motor, stepper or servo for each axis, or do I just use servos on every axis? Along the same lines, should I stick with a single controller or distribute the motion control? I'm looking for best-practices in motion control for this new and future OEM equipment.

ALSO READ: The IoT starts with common and proper things

Answers

Single platform

Precision motion control can be defined by network update rate, positioning accuracy, throughput and drive loop closure rates, plus the functionalities listed and safe motion capabilities.

IoT-readiness means supporting standards needed to communicate with the cloud, such as OPC-UA and Ethernet, but we are still defining the architecture in the Industrial Internet Consortium (IIC) and the IIC's Smart Factory Task Group, so it would be a stretch to call machinery IoT-ready.

For control, definitely use a single control platform. Synchronizing motion between multiple controllers costs engineering effort, money (hardware and software licenses), performance (time used to communicate between controllers), space and wiring. One program developed in one software-development environment should run on one processor on one controller on one network cable to run HMI, motion, I/O, PLC, robots, safety, condition and energy monitoring. The technology is there today, all standards-based.

When deciding between servo and stepper and VFD, there are two schools of thought. You can spend a little more, and standardize on servos to reduce maintenance inventory and increase performance, but more likely you will use a mix of servo and VFD and quite possibly steppers, which have gotten more controllable and can be very cost-competitive.

For example, a manufacturer of palletizers offers two options, both using the same inverter drives and software function blocks that can run both servo motors and induction motors. The motors replace pneumatics completely, so they differentiate as the only all-electric palletizer. For customer that require higher performance, they have an all-servo option where the induction motors are replaced by servos (same drive rack, same controller).

John Kowal

Director, business development

B&R Industrial Automation

Centralized control

As you work on a motion control solution for a complex machine, you should break down the machine into the mechanical structure. Following the mechanical structure of your machine, define each part of the machine, such as infeed, different functionalities of the machine and outfeed.

If all of the mechanical modules are defined, you can use technology modules to realize the single application parts. This is a typical controller-based solution. The controller, as the brain of the machine, controls everything using technology modules. If most of your machine’s axes are servo axes, it’s best to use only servo axes. But a one-drive solution is able to run a standard motor or a servo motor.

When you have a controller-based solution with technology modules, machine information is centralized in one place. The controller can be connected to the Internet and the cloud, giving you the necessary machine information, allowing you to meet your IoT requirements.

Daniel Repp

Business development manager of automation solutions

Lenze Americas

Pros vs. cons

Today in automation, there is no concept more popular than the Internet of Things. The underlying idea, of course, is that we are moving toward architectures made by components (drives, sensors) that are smart and connected enough to run independent functionalities, such as energy management, self-diagnostics and email notification. At this point though, there are very few hardware components available that have that level of brain and certainly not enough of them to cover an entire complex architecture.

PLCs, motion controllers, and industrial PCs (IPCs) are still the parts of the machine that collect data, run diagnostics and connect with the outside world for analysis, service and maintenance. As per how to implement the control system in a complex machine, there are two different approaches—centralized architectures and decentralized architectures—both with pros and cons.

Centralized: Typically run by an IPC or a powerful motion controller, it’s an architecture with only one controller running the entire system managing motion control, the logic control and the process control elements.

Pros:

- one controller (reduced upfront cost)

- one program (all the variables and the information are at hand in the same program).

Cons:

- program complexity (the code has to take care of everything)

- loss of modularity (adding or removing parts of the machine requires severe changes of the code).

Decentralized: Typically run by a process PLC or an IPC as supervisor, the different functionalities of the architecture become modules with each one handled by a local controller (motion controller or PLC, depending of the task).

Pros:

- local programs are easier to write, maintain and troubleshoot

- modules are easier to build, wire and service

- more IoT-like architecture (not many smart components, but smart modules).

Cons:

- each module needs a controller (higher upfront costs)

- each module controller needs to exchange information with the supervisor controller (more coding to ensure proper communication and variable exchange).

- Regardless of the architecture chosen, there are a few best practices that would offer advantages to an OEM developing complex architectures.

- Use programming software which includes PLC and HMI programming and drives commissioning in one package. This will reduce the development of the software aspect and will focus the maintenance and service crews to a single platform.

- Where possible, use a single vendor that can provide the whole solution. This will minimize the time and the hassle of making the different hardware components talk to the controller(s).

- If there are reasons to not select one vendor for everything (end-user specification or specific functionality requirements not available from that vendor offer), pick vendors that offer hardware open to third-party equipment, possibly with libraries and/or programming examples that can be provided.

Simone Gianotti

Motion product manager

Schneider Electric

Pneumatic positioning

Dependent on the application, pneumatic positioning and motion control could be used as an alternative. This may provide a better return on investment versus precision stepper controls with a lower price point to the market, especially in areas requiring washdown and IP-rated products. Many operations performed in automation are very well suited for pneumatics, often involving repetitive fast-moving tasks that involve linear and/or rotational motion. Pneumatics can offer 100% duty cycle without heat buildup when compared to some electrical solutions and offer condition monitoring providing IoT-ready features such as valve-level diagnostics and condition monitoring solutions.

Mark Densley

Head of product management—controls

Aventics

Balance cost and performance

There is a difference between what a sales department asks for and what it can sell. Machine designers and engineers are constantly tasked with the job of balancing cost with performance. Deciding to select all servos and the highest-performing control is often not the best choice.

Regarding the controller, I would recommend using an embedded control or industrial PC (IPC) where you can. Create modular, brand-free code; use existing motion function blocks; and implement a synchronized motion fieldbus such as EtherCAT. Using an embedded subcontroller for the three-axis gantry would simplify your overall machine control, but distributing the controllers further may simply add cost to your machine.

Servos are not always the best choice in motor technology. AC motors and drives perform well where the rotor inertia doesn’t hinder performance, such as conveyors, master-followers and tension systems. Servos are typically the best performers on robots and high-speed gantry systems, where their high torque-to-inertia ratio really shines. However, if the gantry system is large, then servos lose their dynamic edge and ac motors meet the need. Small, subfractional hp applications can utilize stepper systems. In any case, choose a drive system that can be linked to the motion fieldbus. You will reduce machine wiring, ease motion control, improve machine troubleshooting, gain data collection and improve machine serviceability. Connected drives can be programmed automatically and are reachable via remote access.

Don’t forget remote access. Customers expect fast responses when something goes wrong. Using a secure, reliable remote device will pay for itself with the first trouble call.

Scott Cunningham

Engineering manager

KEB America

From simple to complex

Figure 1: When a multi-axis system is required, customers can look to modular VFDs.

The newest product lines on the market offer controller platforms and flexible multi-axis systems that perform both complex and simple automation and motion control tasks. When a multi-axis system is required, customers can look to modular VFDs (Figure 1). These modular systems have the ability to handle precision servo control and master-slave functions, as well as controlling simple applications such as variable-speed conveyors, tension control and winding applications. With the ability to run synchronous or asynchronous motors with or without encoder feedback, it isn’t necessary to purchase servos for every axis. State-of-the-art features like this allow customers to be cost-effective with their motor selections, while ensuring a perfect solution for their applications. When it comes to deciding on how many controllers to use, companies make it simple, providing powerful controllers with high performance that can handle several axes, eliminating the need for several controllers on a single machine. With some of these advanced controllers, you can choose from a wide range of application modules, from positioning, to robotics, that are simply configured and require no programming experience. For the advanced user, a fully operational programming environment that allows the user to program the machine exactly as they see fit is available.Jason Oakley

Electronics product/application engineer

SEW-Eurodrive

Flexibility is vital

Figure 2: New capabilities in today’s control allow machine builders to develop all-new, customer-specific ways to interact with, monitor and manage their machines, including mobile-device based interfaces.

Based on the application and functions described, the OEM would ideally use a control platform that has open interfaces to third-party automation products (RF sensors, vision systems, glue or heater controls). The control needs to be capable of interfacing with all of the mentioned motor technologies (Figure 2).

The control the reader ultimately chooses should offer functional libraries already developed for robotic and winding/tension functions, so that he or she will not have to create them from scratch. For winding control, as an example, and robotics, the OEM can simply choose from pre-engineered libraries and/or function blocks, and thus will not have to reinvent the wheel. The engineering time savings are considerable, eliminating much of the usual additional calculations and math needed for these types of motion segments.

To answer the reader’s question about single vs. distributed control, what it really comes down to is how the OEM’s machinery is ultimately sold. One control can certainly handle all of the functions described; however, if the OEM offers individual elements of the machine for sale separately, it may be of benefit to offer the machine with multiple controls.

To help this OEM’s sales organization, the most important technology choice for precision motion will be in the drive technology chosen. Clearly, servo motion is the most precise for critical motion elements in the machine.

As for IoT-readiness, this can mean a lot of things. What will be important for the OEM’s sales team is to help end users of their machines to understand how the IoT benefits them specifically. In the type of application described by the reader, IoT-ready typically means machine connectivity paired with good data analytics—in other words, IT functions bridged out of the control to another system. Technology can connect to the cloud, display key information visually via mobile devices, synchronize machine data with management and decision-oriented dashboards and provide predictive maintenance elements. These capabilities offer a lot of flexibility to end-user customers—flexibility, which is vital, because every company’s IoT needs are very specific and individual.

Dave Cameron

Director of sales, electric, drives & controls

Bosch Rexroth

Real-time control

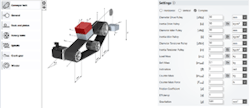

Figure 3: Conveyor systems are often seen as more basic elements of a machine, but, if you need a vertical conveyor or a conveyor with a tensioner or counterbalance weight, software with the ability to easily make adjustments upfront in the design process is incredibly valuable.

Precision motion is much simpler to achieve today than it was just seven or eight years ago. One reason for this is that controls engineers have embraced real-time control systems and real-time fieldbuses such as EtherCAT. This provides the ability to retrieve actual and setpoint positions on the fly without interrupting data throughput, as can happen with other fieldbuses. Advanced functionality, such as distributed clocks, provides highly precise timestamps on measured values and events that occur in the overall system. On the heels of this movement, drive vendors and encoder vendors have begun to standardize on the same real-time fieldbuses. When using a fieldbus that has the same precise time base, external encoders can be used that might deliver higher resolution than the encoder already on the servo motor in the application. Today, manufacturers have increased the capabilities of servo encoders to feature higher resolution, and, as a result, drives are easier to configure to the reference external feedback. The precise verification of a position leads to much more precise motion control overall.

IoT concepts have already entered the realm of machine control, enabling access to larger amounts of highly accurate data for analysis. This is the biggest reason why IoT is now being accepted into motion applications. Motion-related data, such as axis torque or velocity, can be stored for viewing in dashboards that help users to understand events as they happen. This includes events that are predicted and those that aren’t. Fortunately, the high costs of third-party IoT hardware and software can be eliminated in PC-based control applications. PC control adds further benefits through the use of open, proven protocols for cloud communication such as MQTT or AMQP. Accessing this data, whether locally or remotely through a secure, cloud-based message broker, becomes very easy with system-integrated solutions.

With all the different motion-control requirements on the equipment, do I mix and match the best motor, stepper or servo for each axis, or do I just use servos on every axis?

When you work with a motor vendor, they will provide a number of viable options for your application. However, your knowledge of the exact system mechanics is far greater than that of the vendor, so you should also use a motion designer tool or other sizing software that can be adjusted to your application.

The cost and size of servo-motor technology and drive systems are continually decreasing, enabling the use of servo motors in more cost-sensitive applications. Power stages that can handle capacitive and regenerative energy have also helped to cut costs. Stepper technology on the drive side has improved dramatically, extending the life of the motor and drive, while narrowing the performance gap with some servo solutions. Current controller optimization facilitates performance increases, enabling the use of steppers in motion applications without fixed speeds and repetitive motion profiles. With the need for technological advancement on one side and the need for cost reductions on the other, a platform that enables flexible hardware changes is critical in cases where a stepper motor needs to be switched out for a servo motor, for example. The principle of abstraction inherent to a PC-based control system facilitates reduced rework on the application programming side, boosting flexibility and code reusability.

Conveyor systems, for example, are often seen as more basic elements of a machine. However, if you need a vertical conveyor or a conveyor with a tensioner or counterbalance weight, software with the ability to make adjustments upfront in the design process is incredibly valuable. This can also help you to determine where servos or steppers are more appropriate on specific parts of a machine, from simple to complex (Figure 3).

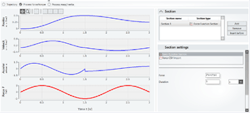

Figure 4: The ability to enter engineering equations for automatic calculation makes it easy to realize exact acceleration and torque requirements for the full range of the application.

Motion profiles are necessary to fully understand the motion requirements of the application, specifically if the load or forces on that load change as it moves or if a complex motion profile needs to be created for the application. The ability to enter engineering equations for automatic calculation makes it easy to realize exact acceleration and torque requirements for the full range of the application. This also helps to verify that a chosen motor will work for the application (Figure 4).

Real-time fieldbuses, when paired with the higher-end processors found in PC-based controllers, enable efficient motion-system design in a single, unified platform. Even if this performance isn’t required for the application, a system that can be synchronized with an external controller is necessary to avoid complex synchronization. Note that some industrial Ethernet fieldbuses used for motion require special switches and hubs, which add cost and setup time. They can also hinder OEMs from making their applications better than, or even simply keeping up with, competing machine builders. EtherCAT is an example of a protocol that can be used as the complete motion system bus and does not require switches, managed or otherwise. A final important aspect to consider is industry trends. As more manufacturers of servo, stepper and vector drives support fieldbuses like EtherCAT, it indicates real traction and acceptance, enabling integration by machine builders without fear of obsolescence or nonconformance.

Matt Prellwitz

Drive technology application specialist

Beckhoff Automation

Seamless integration

We receive frequent requests from OEMs looking to integrate multiple disciplines of control: PLCs for logic control; robot control for loading, unloading, assembly and inspection; motion control for printing, converting, assembly and packaging operations including winding, tension control and registration; and CNC control for cutting, drilling and other machining operations. Of course, with so many complex operations occurring in one machine, it’s critical that all of these processes share data to ensure that the equipment is running optimally. This need for visibility is the origin of the IoT-ready movement. We have a concept we call e-F@ctory, which allows seamless integration from ERP and MES down to individual components within a machine on the shop floor. We developed this technology to optimize our own factory productivity and efficiency, and now our customers can benefit from this off-the-shelf IoT solution.

At the heart of e-F@ctory, the platform integrates PLC control, motion control, robot control and CNC control all on one controller. In your example, a motion CPU would handle the tension control, unwind, wind and conveyors, as well as the gantry and automatic changeover adjustments. The PLC CPU would manage the machine sequence, I/O and communications with other equipment. The MES interface module allows a direct connection to the MES’s database without additional PCs or middleware. This can be used for fetching jobs from the server, downloading recipes, automatically configuring product changeover adjustments and reporting of production statistics and traceability data, all without clipboards, memory sticks or manual data entry.

We prefer to use servos and VFDs, rather than stepper drives, for one simple reason: data collection. For axes that require positioning, there is no substitute for a servo drive and motor to ensure positioning accuracy with closed-loop feedback. The servo motor’s encoder position is continuously monitored by the servo drive and the motion controller. This, as well as other data including velocity, torque, load inertia and real-time energy consumption, is available for monitoring and improving your process. Stepper motors, on the other hand, are an open-loop system. Position commands are sent to the stepper drive, but, unless an encoder is used, you can only hope that the motor reached its target position and has not been nudged out of position later. The stepper drive and motor also consume a considerable amount of energy. A small investment in upgrading servo drives and motors upfront gives you seamless visibility into your process, reduced energy consumption and motion precision and speed that steppers can’t match.

Variable-frequency drives are a cost-effective way of operating conveyors and other velocity-control operations, with significant energy savings compared to motor starters. Variable-frequency drives also provide extensive options for energy saving and process monitoring, for an easy IoT implementation.

You don’t have to choose between the complexity of integrating multiple distributed controllers or trying to fit a complex machine in a single CPU. You can mix PLC, motion, robot and CNC CPUs on one controller to get the best of both worlds: the best tools for the job with the ease of a single controller. These features translate directly into selling points that differentiate your equipment from your competitors. Your system has the precise motion and IoT features your sales department and customers want, with an easy-to-integrate solution your engineers will appreciate.

Bryan Knight

Product manager & automation solutions team leader

Mitsubishi Electric

All-servo solution

There is no one answer that will fit all machines and in many cases different implementations of the same machine type will call for different solutions given the specifics of the implementation. The key factors will be cost, performance, ease of connecting various products together in the control system and experience of the user with the various technologies.

One solution mentioned, an all-servo solution, will have benefits for many applications.

- High-bandwidth precision motion results in higher-quality product and throughput in printing, converting and packaging applications.

- Use of a common high-performance motion bus such as EtherCAT with software in the machine controller reduces system integration time.

- With the motion bus, the machine developer has the flexibility to integrate servo drives, stepper drives, safety devices and other third-party devices. Given the popularity of a motion bus like EtherCAT, there are hundreds of automation products that support this network that could be integrated into the machine control system.

- All the EtherCAT devices connect to a central controller for a streamlined machine-control system. If a decentralized system is preferred, multiple controllers can be used that communicate with each other.

- The motion bus is structured for passing information such as command and recipe information to the devices or diagnostic and status information to the central controller.

- Servo drives can be connected together to transfer power from a regenerating axis to a generating axis, thus preventing the need for external heat generating power-regeneration resistors.

- Servo drives offer a variety of feedback devices to optimized position accuracy, cost goals and ruggedness level that the application requires.

- In machines with multi-axis gantry, the controller and servo-drive motion can coordinate motion between multiple drives to provide the dynamic motion compensation needed for proper gantry motion control.

- Servo motors come in multiple types, allowing optimization for each motor on the machine: traditional tube-type motors to direct-drive rotary or linear motors where extremely high precision and dynamic response are required.

The controller utilized in the system can also integrate into the system non-servo motors, such as steppers and VF ac driven induction motors, where all the performance of a servo is not required or where cost is the main design factor or a high-horsepower motor is needed. As mentioned, the EtherCAT network makes integration easier and facilitates the same wide range of information that can be shared.

Carroll Wontrop

Senior system engineer

Kollmorgen

Simulated control

It is most logical to use an appropriate type of motor to match the application requirement, based on the intent of the machine part it is used with. Therefore, having multiple types of motors, as well as sources of power, is a common scenario. There is a lot of literature available about centralized vs. distributed control that can guide the reader on this decision. However, one can easily understand the reader’s dilemma in making the architectural decisions for a fairly complex piece of equipment. This is where simulation can play a big role. Simulating the machine behavior, as well as the control system, can be a great way to assess various system architectures and control system behavior. A case study from Tetra Pak showcases the use of simulation systems for machine design.

Jace Allen

Lead technical specialist—simulation & test systems

dSpace

Synchronous servo

Given the cost point and functionality of current synchronous servo motors and respective control, we would suggest considering a design based on synchronous servo motors wherever possible. The only exception would be where the power requirement is large, say 20 kW or greater; in these cases, an asynchronous servo motor may fit the application better. However, a drive system that can be configured for either motor type should always be considered.

A centralized motion control platform seems to offer more benefits from programming and support and ease of use. Only in the case of a modular hardware requirement would a decentralized control system be the preferred choice.

William Gilbert

Converting market manager

Siemens Industry

Mike Bacidore is the editor in chief for Control Design magazine. He is an award-winning columnist, earning a Gold Regional Award and a Silver National Award from the American Society of Business Publication Editors. Email him at [email protected].