A machine builder’s path to build and install tobacco equipment in China

With machinery in 59 countries, I finally got a chance to go to China in 2017. As the chief electrical engineer doing 90% of the PLC and HMI programming, I didn’t always get to go overseas because we had service technicians that would do the installations. Occasionally though, when we were loaded up with jobs and someone had to go, I get the opportunity to travel. But, even though we did jobs in China throughout 1993 and 1994, I never had to go until now.

My equipment company has been sold twice, and people have been cut for austerity measures, so I am now traveling more than ever. We build tobacco-processing equipment. There are essentially four areas in the art of processing tobacco leaves supplied by the farmers, already dried:

- Conditioning—where the tobacco is set to just the right temperature and humidity for

- Thrashing—where the paper parts of the leaves are separated from the stems, the woody fingers of the leaves

- Redrying—where the humidity is set for long-term storage

4. Packing and labeling—this is the part our machines do. It takes a tobacco press about 80 feet tall, pushing with about 37 tons of force to make 200 kilograms of tobacco fit into a cardboard case (Figure 1). The usual production rate is 60 cases per hour.

Figure 1: The tobacco press is about 80 feet tall, pushing with about 37 tons of force to make 200 kilograms of tobacco fit into a cardboard case

This job, for Qinhuangdao Tobacco Machinery, was a typical 34-foot-stroke, twin-ram tobacco press (Figure 2). Two rams are supplied, so that one can be filling while the other is packing, thus no interruptions to the flow of tobacco to the press.

Figure 2: The machine, a typical 34-foot-stroke, twin-ram tobacco press, was built for Qinhuangdao Tobacco Machinery.

In this job, the Chinese wanted to do all the support equipment. We did only the press, and they did the conveyors and accessories (Figure 3). The control design was based on Rockwell Automation’s Allen-Bradley CompactLogix series L35 processor with remote Flex I/O in two operator cabinets and a pump-unit remote-rack cabinet, all running on an Ethernet network.

Figure 3: Our field technician (from left), our Chinese interpreter, Zhou, and Stephen Jones are dwarfed by the 80-ft-tall press.

I used simple AutomationDirect unmanaged Ethernet switches. The system also included five Allen-Bradley PowerFlex 400 series variable-frequency drives (VFDs) from Rockwell Automation for the hydraulic pumps and two PowerFlex 40 VFDs for the feed system, all with Ethernet adaptors.

The system should have also included a network-address translator (NAT), but I left that responsibility up to the Chinese engineers, so I hope they included one. Using a NAT device such as Rockwell Automation’s Allen-Bradley 9300-ENA module keeps the area Ethernet traffic out of the PLC and its I/O network, which can be critical if you need good Ethernet speed, such as for tension control between motors in a web system.

Since our equipment must receive empty cases from the Chinese input conveyors and then hand off the full cases to the Chinese output conveyors, the Chinese and I composed a set of “produced” and “consumed” tags for our processors. Each of us owned the produced tags, which became the consumed tags for the other PLC.

To do this, you must actually add the other processor to your I/O structure so that, when you create the tags in your controller tags table, you can point to the other PLC as the communications device for the produced and consumed tags.

The beauty of using tags of this type is that the communications is intrinsic to the processor operation. No messaging is needed because all of the tags are automatically updated by the processors to the other processors. Our set of tags included reals, integers and bits, so we made a custom data type for each PLC’s produced tags and then designated them appropriately as “produced” or “consumed” in each processor.

We also included a watchdog bit that would toggle every second and would produce an error message if it failed to change state in two seconds. We each also used that failed status to disable equipment that was being commanded into operation by the other PLC’s produced tags.

Finally, I showed all of these bits, integers and reals in a Panelview screen showing the Chinese what I was sending them and what I was or wasn’t getting from them. That screen sure cured a lot of malfunctions and “arguments” quickly with the Chinese when things didn’t work right with the operations.

For control devices on the press, we usually use Rockwell Automation’s Allen-Bradley 802T limit switches, Turck 30 mm proximity sensors and Sick photo eyes, specifically the WT260 retroreflective type.

We like the Allen-Bradley limit switches because they have been tested to survive millions of operations, and we have never had a callback on them. We use the Turck proximity sensors for no particular reason except that we have also never had a callback on them.

We have also used Omron’s E3G series photo eyes and Omron’s E2E series unshielded proximity switches with good results. Both the Sick and Omron photo eyes handle universal voltages—24 V to 240 V ac/dc, which makes them possible for use with all of the control voltages we encounter.

In the motor control center (MCC), we use either Siemens or Rockwell Automation motor contactors with motor circuit protectors, as well as Siemens circuit breakers, AutomationDirect terminals and distribution blocks and Panduit wireways. All VFDs are the same brand as the PLC, which in this case is Allen-Bradley.

In the operator controls cabinets we use remote racks by the same brand as the PLC manufacturer—once again, here it is Rockwell Automation’s Allen-Bradley—Rockwell Automation push buttons and pilot lights, AutomationDirect terminals and Panduit wireways.

We usually use Rittal for all of the cabinets, and we include fans with filters, or we include air-conditioning systems if the factory environment will be hot.

We use AutomationDirect five-port and eight-port unmanaged Ethernet switches in every cabinet and have had great success with them. We also usually include Rockwell Automation’s Allen-Bradley 9300-ENA network address translator module when using that same brand of PLCs. Finally, we use an AutomationDirect door-mounted Ethernet port with power outlet on the PLC cabinet door.

The press is driven by two 40-hp motors at 380 V, 50 Hz to power the hydraulics. Whenever I order VFDs for these pumps, I always get the next-highest-rated drive, in this case 50-hp drives, to be sure there are no current overload issues, since we tend to push these motors over the limit for short periods of time.

Originally, we used star-delta motor controls to reduce starting currents because most countries’ power infrastructures could not handle the current draw from across-the-line starting. In the late 1990s, we switched to soft-start motor controls, which worked well, allowing us to buy three-wire motors instead of the six-wire ones needed for star-delta starting.

In the early 2010s, we went to VFDs for the pump motors, chiefly so we could network the drives and get all the benefits of start-stop commands, drive status, drive-speed manipulation and actual motor speeds via the network. The only control wiring we do to the drives is the safe-stop input circuits controlled by the emergency-stop safety relays.

By using the VFDs we have an even greater advantage. Originally the motors always ran at the rated speed. This means they were always pushing the oil, even though, while not performing work, they were still putting heat into the oil. So, we would also supply an oil cooling means, either oil/air with a fan or oil/water, usually by the customer.

When the oil reached 105 °F, we would energize the fan or open the water valve. If it reached 140 °F, we would warn at the HMI that the oil was getting hot. When it reached 155 °F, we would shut down, because the oil would chemically break down at temperatures higher than that.

Now, with the VFD, as soon as the hydraulics finished doing any part of the job, the pump motors are dropped to 20 Hz or so in 1.5 seconds, which is just fast enough to keep a decent air flow over the totally enclosed, fan-cooled (TEFC) motors and keep oil flowing through the cooling loop.

Three more benefits are reduced noise, reduced power consumption and cooler motors and oil. After doing this on the China job, the cooling system might come on near the end of the day and go right back off after a few minutes, and you could put your hand on the motor and feel it at about 95 °F, which was awesome. I have the VFD accel rate set to 1.0 seconds and the decel rate set to 0.5 seconds, so the response is really fast when the next hydraulic operation is needed.

If the press has been idle for more than five minutes, I set the speed to 0.00 Hz. The PowerFlex 400 drives accept the 0.00 Hz speed command and are still active but consume almost no power.

I tried to do the same thing with customer- specified Danfoss drives on another job. The minimum default value for the motor frequency is 10 Hz, but it could be changed to 0 Hz if you want. Instead, I shut the drives run command off and kept on the status that the drives had been started, so they would automatically come back on whenever a hydraulic operation was called for. It is not really a good idea to run a motor at single-digit Hz when using a VFD, but 0 Hz is OK. I have to shut off the drive but keep alive my need to restart them as soon as a hydraulic operation is needed.

The only problem with running at 0 Hz is the carrier frequency is still active, and it would drive the super-sensitive-hearing plant electrical engineer I had on an India job crazy when he went into the pump room during the quiet time. I think he was hearing some harmonics in the 20,000 to 25,000 Hz range.

Working in China was a very nice experience for me. We were in a small city called Zunyi which is about 680 km northeast of Kunming and about 990 km south of Xi’an, located in the mountains of central China. We flew into Beijing and then took Air China for about a 2.5-hour flight to Zunyi. We were put into a new hotel less than one year old, 46 stories tall and fitted with polished marble everywhere (Figure 4).

Figure 4: Our hotel was less than a year old. It was 46 stories tall and fitted with polished marble everywhere.

Two adjacent sides of the hotel are outfitted with LED graphics the full height of the tower that is used to display messages and graphics after dark (Figure 5).

Figure 5: Two adjacent sides of the hotel are outfitted with LED graphics the full length of the tower that are used to display messages after dark.

The TV station was always default set to CCTV, always full of good news, mostly about what the government was up to, both politically and militarily. They also reported on world events, including national news items of the United States, such as the California wildfires.

When you walk about the city, you see basically happy people. Everyone goes to work, earns their pay, goes home, pays their bills and buys their cars and groceries and other goods, just like in any other country. Many businesses are privately owned, alongside government-owned businesses. The agent who brought us into the project is an independent Chinese agent, Lucius Hong, director and managing executive at Smartech International Commercia in Hong Kong, but the factory and most of the other equipment suppliers are government-owned.

Driving through the city I noted that everyone has cars manufactured in this decade. The only older vehicles I saw were taxis, all Hyundais and Volkswagens, and vans. The most popular American car brand I saw was Buick. Very few Chevrolets or Fords were there. There were a lot of Mercedes, BMW and Audi vehicles. I even saw a Lamborghini parked at the hotel one day. Apparently, there is no lack of prosperity.

The person who drove us to and from the job site had a brand-new Nissan, and, thanks to the new graphic displays, he could enjoy the use of the Chinese language in his information access.

I also wondered how the Chinese can use a standard cell phone when they have a “picture language.” I learned the pictures actually just represent sounds, sort of like our characters do, except they are harder to draw. One way they do it is to type English letters to create the sounds these Chinese characters represent, and then the phone supplies them with a suggested matching list of characters from which they select the right one. The other way is to turn the phone on its side which opens up a manual-drawing screen, and then they just draw the character with a finger.

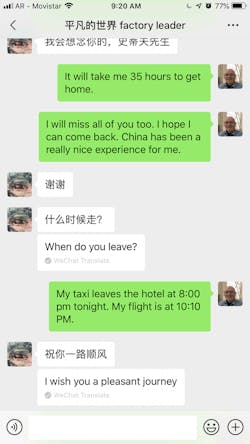

“What good did that do me?” you ask. The Chinese use an app on their phones specially written for China called WeChat. It’s like WhatsApp, which is what most of the world uses, except it is more powerful (Figure 6). The Chinese person standing next to me would type me a message in Chinese, and then I would hold my finger on the message to get a pop-up menu that included a translation function. The message would then be translated completely for me to read.

Figure 6: The Chinese use an app on their phones specially written for China called WeChat, which is similar to WhatsApp. A Chinese person can type a message in Chinese, and then the receiver can hold a finger on the message to get a pop-up menu that included a translation function. The message would then be translated completely.

The Internet is interesting in China. The Chinese government has firewalls on all social media and all things Google. You can use the Chinese search engine called Baidu, or you can get access to the firewalled content by a few different methods.

I opted for using a virtual private network (VPN), which cost me $99 for 12 months. I kept my cell phone in airplane mode the whole time I was there and used the VPN whenever I could get Internet connections at the hotel or at the factory. Sometimes those networks would recognize I was using the VPN and then would cut off my connection. If I then turned off the VPN, I could retrieve it.

My luggage was six days late, arriving at my hotel on my second trip. I had to reroute out of Atlanta at the last minute because of a flight delay, and my bag didn’t make it with me, so I had to go shopping for some clothes and toiletries.

My hosts first took me to a shopping mall, but the men’s clothes were all too expensive because they were not “work clothes,” so I asked them to take me to Walmart. They laughed and said that the clothes at Walmart are cheap. But they took me to a Walmart Superstore, which occupied all of the second and third floors of a skyscraper downtown. When the American ahead of me tried to pay for his purchases with a Visa card, he was asked for a password, which is not the same as a debit-card code. I had enough Chinese cash with me to cover both of our purchases, so I lent him the money.

The shopping mall was a real revelation for me. Easily 70% of the shops were world-brand women’s cosmetics, 20% were women’s clothing, 5% were food outlets, and the remaining 5% were men’s clothing. The prices were comparable to our prices for the same goods in the United States.

Speaking of money, there were banks everywhere, sometimes two or more in the same block, but none of them had an ATM we could use except Bank of China, and that ATM was only open during certain hours. Fortunately, the nearest branch was only two blocks from our hotel.

I asked our Chinese translator, Zhou, if the government deducts income tax from his pay. He didn’t understand, so I asked if they take money out every paycheck for themselves? He somberly looked at me and sadly said they take 10% of it. I told him the U.S. government takes 25% of my paycheck. I also asked him if the Chinese government supplies any social welfare. Once again, I had to explain what this was. He said, if someone is handicapped or disabled and unable to work, that person can get monetary assistance from the government. But if you can work, you will get a job.

I also asked him about social security, and his reply was that you can get money from the government after you retire only if you have no money and your family has no money. Otherwise you support yourself.

All in all, my trip to work on a job in China was a very positive experience. Like people everywhere, if you are nice to them, they are nice to you in return.

ALSO READ: A walk down automation programming memory lane

Leaders relevant to this article: