How IEC terminal blocks impacted control-panel design

Terminal blocks are not that exciting to most engineers, I’m sure. They form a major part in any control panel with any type of automation hardware installed in it.

Termination points in any system are required for many reasons, such as the programmable logic controller (PLC) I/O wired to a terminal block in an assembly shop. This allows the engineer to bring the sensors and devices into and out of the control panel when it arrives on site.

When I was working with Allen-Bradley (AB), which is now part of Rockwell Automation, in the 1970s and 1980s, its terminal-block line was the 1492 series. They were an AB design and locally manufactured. They were robust with big screws, and they included all of the things that you would have needed to be successful, such as end blocks and gang strips to connect multiple blocks together—like a jumper for multiple blocks.

Then came Weidmuller and its line of IEC-based terminal blocks. One of the main reasons this development caused an uproar in AB terminal-block land was the fact that you could fit three IEC terminations in the physical space of one 1492-CA1 block.

Panel oversizing was going to become a thing of the past due to terminations. I remember being in the panel shop at AB in Cambridge, Ontario, and seeing a double-door 80-inch-high-by-60-inch-wide panel with a 1774 PLC processor and I/O on one side, and the other side completely filled with terminal blocks and wireways.

While I have no idea if IEC-type blocks would have allowed for a smaller panel in this case, the sight of hundreds of blocks in that space was a thing of beauty.

The 1492 lineup of blocks were not competitive with the IEC designs. When they first hit the North American market, I remember a conversation that my district manager had with the vice president of sales for my local distributor. It kind of went like this:

“You will not stock the IEC terminal blocks in any branch. The distributor agreement specifically states that you cannot have any competing product on your shelf, so you have to get rid of all those blocks immediately.”

Response: “I have to sell them, so you are saying we can’t restock after that?”

Answer: “Yes.”

After a short silence, my district manager stated, because he knew that AB would lose projects over terminal blocks: “What you do after I leave is something I don’t want to know about.”

How’s that for a nod-nod-wink-wink moment. And, yes, they kept selling the IEC blocks and we lost about .05% of our business with the distributor.

One of the huge advantages with the IEC blocks was the simple fact that you could remove a center pin to disconnect without having to physically remove the wire. It was simple, but effective.

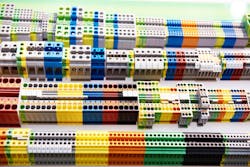

They were stackable and made from hard material and were much easier to install and keep organized. The amount of options made the decision by distributors understandable.

These days terminal blocks are the bullpen of automation. The ability to have multiple methods of connectivity via snap-in connections and screw terminals is wild in comparison to 1977.

In fact, the ability to have power terminal blocks is there with all the same features as control terminations.

The first time I had the privilege of working with IEC blocks was about 30 years ago. I couldn’t believe the fact that such a small block could be rated as it was.

The panel size was the benefit for sure, but the ability to better tray the cables/wires due to the stacks was crazy in my mind. There was an issue of wire bundles and the flex, but by and large the benefits outweighed the downside.

One of the big advancements with using these smaller blocks was the crimp on pins used to insert into the terminal. The issue of fraying wires was to be no more.

There are so many options for connectivity with push-in technology, tension clamp and snap-in, and the ancient method of screw terminals allows the user to select a favorite for the job.

High-vibration installs may require a different methodology than a fixed cabinet. On-machine installs with remote panels benefit with reduced real-estate requirements.

History has shown us that the mother of invention is alive and well. Terminal-block system design is an integral part of the control panel. Selection is critical in some cases. Standards really don’t apply as such. It’s all application-based now.

Control and power terminal blocks help the process and maintenance of the process and the control systems. Troubleshooting is a big beneficiary, as well.

About the Author

Jeremy Pollard

CET

Jeremy Pollard, CET, has been writing about technology and software issues for many years. Pollard has been involved in control system programming and training for more than 25 years.