Containerization technology can enhance automation system integrity and scalability

Imagine that you wrote a simple software program and shared it with coworkers to show off your accomplishment. You email them the application, they try to run it, and they cannot. Consider the number of reasons it might have failed:

- Do they have Mac, Windows, or Linux?

- Are the necessary libraries installed?

- Is the required runtime environment for the programming language installed on their computer?

Get your subscription to Control Design’s daily newsletter.

Consider more complicated reasons it may have failed:

- Is there a difference in the system's architecture (32-bit vs. 64-bit)?

- Does their system have different hardware specifications (central processing unit (CPU), memory, disk space, network interfaces)?

- Are there missing system drivers that the application relies on?

- Could there be a conflict with another application running on their system?

- Could there be incompatibilities with other libraries or packages already installed on their system?

These considerations are an everyday part of software development, and they highlight the complexity of software deployment across different systems and environments, underscoring the challenges developers face in ensuring compatibility and functionality.

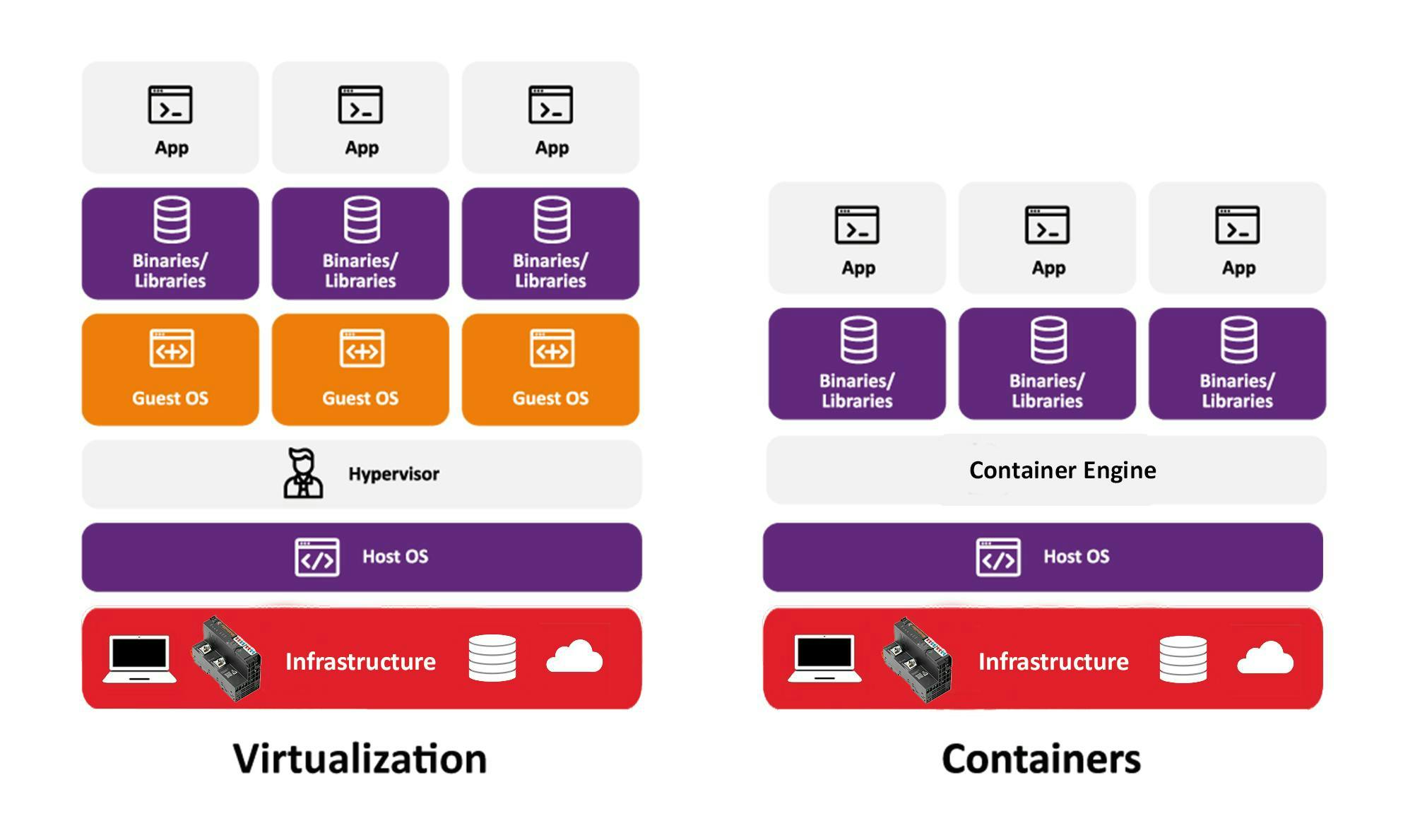

Imagine if there was a way to bypass all these hurdles seamlessly. What if, instead, you could bundle your software program with all the necessary software, libraries and drivers into one package? Containerization allows you to do just that. It encapsulates your program along with everything it needs to execute, ensuring that it can run smoothly and consistently across any system it encounters. Your colleagues would not need to understand your application or its dependencies to run it; they would simply need a program that can run containers.

This is the underlying principle of containerization. It can significantly simplify deployment and execution across diverse computing environments. These containers are self-sufficient environments that contain everything the application needs to run. This encapsulation guarantees consistent application performance, irrespective of the computing environment. It can also provide an additional layer of security since containers run mostly isolated from the operating system of the device. Furthermore, technologies like Compose allow developers to configure one or more containers to the specific needs of your application, enabling you to use the same set of containers in a multitude of applications, each with their respective configuration.

Containerization opens up possibilities

In the rapidly evolving landscape of Industry 4.0, achieving reliable and scalable systems is essential, and companies need to embrace the power of containerization to achieve this. Powered by the connective fabric of the Industrial Internet of Things (IIoT), controls engineers increasingly depend on innovative technologies like containerization for developing systems in all fields of industrial automation.

Containerization’s introduction into industrial automation marks a significant paradigm shift, especially for controls engineers tasked with the design, implementation and maintenance of systems. This technology, which has been used in the IT and cloud industry for a decade already, is pivotal in addressing some of the most pressing challenges in the field: maintaining application integrity, ensuring reliability and achieving seamless scalability across diverse operational environments. Controls engineers are realizing the benefits of containerization in the industrial automation environment in five primary ways.

Isolation

Containers provide a distinct operational environment for each application, ensuring that processes within a container do not interfere with those of other containers or the host system. The industrial automation sector demands a high degree of reliability and uptime. Containerization uniquely supports these requirements by providing consistent environments for applications throughout their lifecycle, from development and testing to production. This consistency is crucial for controls engineers, as it significantly reduces the variables that could lead to unexpected behavior or system failures in production environments. For instance, an application developed in a containerized environment on a controls engineer's workstation can be deployed with confidence to a production machine, without concerns of incompatibilities.

Moreover, containerization's inherent isolation properties ensure that each application runs in a dedicated environment, mostly unaffected by changes or updates in other applications or the underlying system. This isolation enhances the security posture of industrial automation systems by decoupling the application’s dependence on the underlying system, reducing the burden of implementing security patches on the underlying system without disrupting the application.

Portability

In industrial automation, systems are often distributed across various locations and hardware, from on-premise servers to edge devices. Containerization facilitates the management and deployment of applications across these diverse environments, such as when deploying automation control software that can target a physical programmable logic controller (PLC) or a soft PLC running on an IPC. Controls engineers can package applications into containers, complete with all necessary dependencies, and deploy them across the network with ease. This approach simplifies the process of updating applications, rolling out new features, and scaling systems to meet changing demands. This portability supports a "build once, run anywhere" approach, facilitating rapid deployment and scaling of IIoT applications across diverse infrastructures.

Containers also enable a modular approach to system design, where individual components or services of an automation system are developed and deployed independently. This modularity supports rapid iteration and testing of new features or configurations without disrupting the entire system, thereby accelerating innovation and responsiveness to operational needs.

Scalability

The ease with which containers can be started, stopped and replicated makes them ideally suited for environments where application demand can fluctuate. While in the past this scalability has been more relevant to cloud infrastructure, the connectivity of Industry 4.0 enables data analytics to move closer and closer to the factory, and the scalability and speed of containerization makes distributed computing a valuable option for innovative companies. This capability ensures that industrial automation systems can scale quickly and efficiently, meeting the dynamic needs of the industry. It can furthermore lessen the dependence on cloud providers and internet connectivity, reducing the amount of data that leaves the company’s premises and the corresponding cost of data transmission.

Lightweight

The lightweight nature of containers means that edge devices that do not have adequate processing power to host virtual machines can host the same applications running in containers. This increase in resource efficiency is broadening the portfolio of devices able to host containerized applications. This can be observed in the case of new open operating systems for industrial automation which bring a fleet of industrial apps to PLCs, edge gateways, human-machine interfaces (HMIs), and industrial PCs (IPCs).

Economies of Scale

Containerization facilitates the rapid deployment of applications to new technology platforms, significantly accelerating technical innovation by allowing comprehensive ecosystems of apps to be introduced and scaled efficiently.

It furthermore allows easy integration of contributions from the open-source software community. Utilizing proven and well-maintained open-source software, you can increase the security of applications, in addition to the isolation that containerization can provide. When tackling the challenges of Industry 4.0, choosing an automation platform with native support for containerization makes all the difference.

Scalable and reliable systems

In the dynamic world of industrial automation, containerization has emerged as a game-changer, streamlining deployment and bolstering system reliability and scalability. By packaging applications with their dependencies into portable and isolated containers, this technology ensures consistent performance across diverse environments. This approach simplifies the controls engineers' tasks, enabling rapid adaptation and scaling of systems to meet the evolving demands of Industry 4.0. The benefits are palpable: reduced system failures, enhanced security through isolation, and the ability to swiftly deploy and update applications across varied infrastructures, from on-premises servers to edge devices.

Moreover, containerization's lightweight nature and scalability translate into tangible efficiencies and cost savings. It allows even devices with limited processing power to host sophisticated applications, broadening the scope of industrial automation capabilities. This fosters a modular development ecosystem, enhancing agility and innovation in the sector. As industrial automation continues to embrace containerization, the technology is setting the stage for a more robust, scalable, and efficient future, ensuring that systems can adapt swiftly to the industry's rapid pace of change and the increasing complexity of global supply chains.

About the Author

Christopher Deloglos

Christopher Deloglos is strategic product manager at Weidmuller USA. He can be contacted at [email protected].