Flexible and customizable enclosures for complex design

Machine builders are expecting more out of standard enclosures for industrial automation. This is driven by trends in increased networking and cloud communication and the need for this advanced technology to perform in challenging environments. Two manufacturers, Phoenix Contact and nVent Schroff provide some flexible enclosure options that cater to the current demands of device connectivity and their complicated designs.

Seamless integration

Most new machine builds are incorporating IIoT gateway devices that communicate with a variety of existing networks, transmitting vital plant information to the cloud. More plants are also requiring asset monitoring, and, where remote monitoring capability was once the exception, it is now the norm, says Joel Boone, product marketing manager, device connector solutions, Phoenix Contact. Increased functionality has led to more choices and the need for more connection flexibility.

Phoenix Contact has been producing electronic device cases for about 30 years. While its specialty has always been field-wireable connectors, the company also saw a need to accommodate the growing variety of connections needed in complex gateway devices. It created the Industrial Case System (ICS), which can seamlessly integrate a variety of connectivity options.

“As we get into edge computing, and, instead of having all processing power being done in one central location, needing to push computing power to the edge of networks, it’s really important for devices to be able to communicate with a wide variety of I/O and other devices,” Boone says.

Phoenix Contact has always worked with different types of connectors—RJ45s, D-Subs, USBs—by milling whatever necessary holes into its enclosures to accommodate those connections. “That’s just not the cleanest solution for an OEM,” Boone says. The ICS allows for all those different types of connections in the enclosure without costly, secondary modifications, Boone says.

“Machine builders that have been focused on traditional methods of developing an entire system and maybe not looking at cloud computing, that’s kind of not an option moving forward,” Boone says. “End users want to be able to monitor what’s going on with their machines to make real-time decisions to better production, to produce the most amount of yield coming off of those machines.”

Asset monitoring and remote capability will only get more complex, Boone says, and the hardware needs to be similarly complicated, yet adaptable. “Having hardware that matches that complexity is critical to being successful in the market,” he says.

To accommodate a variety of complex connections without off-the-shelf modifications, the assembly is very simple and straightforward. “It all snaps and slides together very cleanly,” Boone says. “The connections are supported with the appropriate openings in user-selected panels that affix to a PCB and then slide into the enclosure.”

The ICS can be modified to match a customer’s brand or aesthetic, and, while its flexibility makes the product customizable for many clients, its ability to be scalable highlights the range of its quick adaptation. “It’s meant to be scaled for someone using 10 or someone using 10,000,” Boone says. “You get a lot of options with it that are easy to configure.”

All this variety and functionality presents some safety issues. With wireless gateway devices, the system must prevent hacking, and cybersecurity concerns are only growing as systems become more complex. “You’ve got to make sure products are safe,” Boone says.

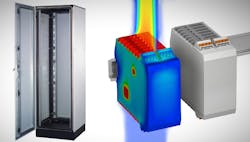

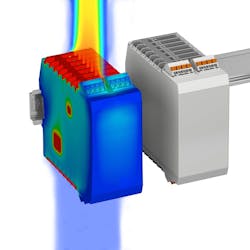

“With all that functionality in one module and one complex set of electronics, you might use system or module electronics or you might build in dedicated functionality that you just tap into for a completed module, so all of that leads to a lot of computing power in a small space. When you have that, you have heat,” Boone says. Electronics also continue to trend smaller and smaller, requiring more heat-dissipation options (Figure 1). “The enclosure that you choose always has to be able to dissipate some heat,” Boone says. “But, if it’s not sufficient in the operating conditions in the end environment, you have to find other ways to get heat out.”

Figure 1: Electronics continue to trend smaller and smaller, requiring more heat-dissipation options.

In addition to traditional venting options, the ICS can incorporate heat sinks that easily slide into the same areas on the enclosures, where users also integrate connection technology. “It’s a really clever design that allows a customer to easily use some of the more complex and hot running microelectronics,” Boone says. “They can be easily incorporated into the system.”

All the components and all the computing power that can be incorporated into the ICS can make for complex designs, so the system also includes an online configurator tool to help with the complicated design process. Boone says he also uses the system on a daily basis with potential customers to look at the capabilities of different systems. “It steps you through, based on the sizing that would make sense for an application,” Boone says.

It’s a graphical drag-and-drop tool that allows users to place components on the digital housing as they want them in the actual enclosure. Once a user has created a full housing, the system provides a full bill of materials and a downloadable CAD file that includes the printed circuit board (PCB) completely configured, based on component selections and layout. It also includes a link, so users can go back and make changes later.

For those concerned about hot spots, the online configurator tool can run a thermal simulation on up to three hotspots. The system can perform an analysis to determine if the layout will cause heat issues or if further heat dissipation is needed.

Levels of protection

The Varistar configurable 19-inch equipment rack platform from nVent Schroff also offers users an online design tool to configure layouts without engineering or software skills. “The user can design a rack that is configured from a catalog of standard components,” says Robert Zeuge, product marketing manager, nVent Schroff. The design tool is Web-based and accessed via the nVent Schroff website, and users receive a bill of materials, a CAD model of the assembly and the needed item numbers.

“The platform is able to be configured for the needs of many different industries and applications,” Zeuge says. Examples of industrial applications for this product include laboratory equipment, industrial test equipment, industrial process control equipment, telecommunications and data-communications equipment, and railway control equipment. Many of those applications operate in rugged and rough environments, requiring protection from many elements. The rack is made of a welded steel frame with steel sides, covers and doors (Figure 2). “There are options for perforations, glass doors and gaskets to seal the enclosure from the outside environment,” Zeuge says. “Other options include a suite of cooling products to manage the heat load.”

Figure 2: The rack is made of a welded steel frame with steel sides, covers and doors.

The enclosure has a high ingress protection, rated on the IP scale (the first letter rates protection against physical objects in the air such as dust, and the second digit represents protection against water or moisture). The standard rack platform is IP20, and the gasketed rack is IP55.

“The gasket that provides the shielding also provides IP55 protection. This feature isolates the equipment inside the rack from outside electromagnetic fields and similarly prevents electromagnetic fields from the equipment inside the rack from interfering with the process and equipment outside the rack,” Zeuge says. This is beneficial, he says, if the equipment or process is sensitive to electromagnetic interference, such as sensitive measurement equipment or a process that uses magnetism or creates magnetic fields.

The Varistar enclosure provides advanced cooling solutions to dissipate unwanted heat. Fans, blowers and air movers cool the equipment inside the rack. “Slightly more advanced would be filtered air movement to cool the equipment, while also maintaining ingress protection against the outside environment,” Zeuge says. The most advanced cooling solutions include air to water heat exchangers to provide up to 40 kW of cooling power to the rack. “The specific aspects of the thermal solution will depend on whether the heat source is the equipment operating, or the outside environment, or both,” Zeuge says.

Along fault lines, upgrades to the enclosure can provide shock and vibration protection for earthquake resistance to NEBS zone 4 and shock resistance in military environments to MIL-STD 901-E.

ALSO READ: Control panel materials and options provide protection inside and outside the enclosure

About the Author

Anna Townshend

Managing Editor

Anna Townshend has been a writer and journalist for 20 years. Previously, she was the editor of Marina Dock Age and International Dredging Review, until she joined Endeavor Business Media in June 2020. She is the managing editor of Control Design and Plant Services.

Leaders relevant to this article: