RoboTape reduces footprint, downtime and safety risks

Innovative Automation, a custom machine builder and system integrator headquartered in Barrie, Ontario, developed the RoboTape platform, leveraging robotics and flexible controls technology to deliver a scalable tape-dispensing system suitable for everything from consumer goods to automotive parts manufacturing (Figure 1).

“Innovative Automation started in 1989 with three founding partners and grew over the years by providing custom automation integration services, primarily to Tier 1 automotive manufacturers,” says Michael Lalonde, co-owner and president of both Innovative Automation and RoboTape.

After three decades of success with custom automation, Innovative Automation formed an R&D department to develop standard automation products. “In the past we had built a number of specialized taping systems, and this experience gave us the idea to create a more flexible solution, which eventually became RoboTape,” he says.

When the company moved into a new 82,000-sq-ft facility, it was time to create a standard model of RoboTape. “It was always in our minds, while we were doing the other projects,” explains Lalonde. “Once we moved into our new building in 2017 and had more space and resources, we were in a position to dedicate people full-time to the project.”

Thirty thousand development hours later, the RoboTape business unit in Newmarket, Ontario, now serves customers globally with several offerings. The base version is available for integration by the end user or with help from a system integrator. The next step is the stand-alone RoboTape Lite work cell with collaborative robot, which provides a low-cost and quick-to-integrate entrance to automated taping technology. For high-volume production, a RoboTape standard cell is recommended which features an enclosed industrial robot. This provides an opportunity for the integration of further value-add operations. The RoboTape System for 3M Tape is another option, born through a collaboration with 3M and offering solutions for a variety of attachment tapes.

Any of the systems can be integrated by the user’s preferred integrator, receiving full support or work directly with Innovative Automation. The system suits all sorts of part geometries and adhesive types (Figure 2).

We have set up a dedicated lab and test cell to run production intent trials with customer adhesives and parts. This testing allows the RoboTape team and the customer to be confident that cycle times and application requirements can be met before committing to a project. This service helps to alleviate any hesitancy to adopting a new technology.

Peeling away common challenges

During the system’s design phase, Innovative Automation engineers identified multiple mechanical and electrical shortcomings of existing options, creating opportunities for innovation.

The main pain points were robot size and maneuverability. Most systems place the tape spool at the end of the robot arm, along with an empty spool to catch the waste liner. This design requires operators to pause production and enter the work cell.

Our main advantage is to keep the material outside of the work cell, so you don’t have any untrained operators entering the safe guarded zone. Instead, RoboTape has built in safeguards so it can operate from outside the work cell. That allows us to use a much larger spool. At a minimum, you’ve got 2-4 hours of operation per spool and at a maximum you can run for a week, depending on the thickness of the material on the spool.

This new remote feeding module is a key to the success. That’s now patent pending worldwide. It also helps with the robot sizing issue and increases system uptime. This is why big automotive clients are latching onto it; it's currently the only solution that solves the entire problem.

The RoboTape system also catches and chops up the waste liner at the remote feeding module outside of the work cell and away from the robotic arm. This is another advancement to make the system flexible. The intention is the system will work with any robot. It’s usually by the customer’s spec, systems have been integrated to robots from Yaskawa, ABB, Fanuc, Universal Robots and others. A payload of 10 kg or bigger is good but we have done it as low as 7 kg depending on the application.

The design optimizations drove robot selection, Lalonde explains. “We were aiming for the 10-kg robot class, so keeping the applicator tool light and compact was a top priority,” he says. “This allows the tool to work in tighter areas and to reduce the overall size and cost of the work cell. These are all things our customers have been requesting.”

It wouldn’t be possible if it weren’t for RoboTape. A smaller work cell can help free up floor space to take on more work.

Before RoboTape was ready for prime time in tape dispensing, a variety of challenges had to be overcome first. The team had to effectively accommodate a wide range of robots, continuously adapt to new parts for taping processes and gather massive amounts of sensor data for rapid processing. All these demands ultimately led the R&D team to PC-based control, although being able to incorporate the data collection wasn’t a primary initial focus. "That was a benefit of having that capability on the base controller," explains Lalonde.

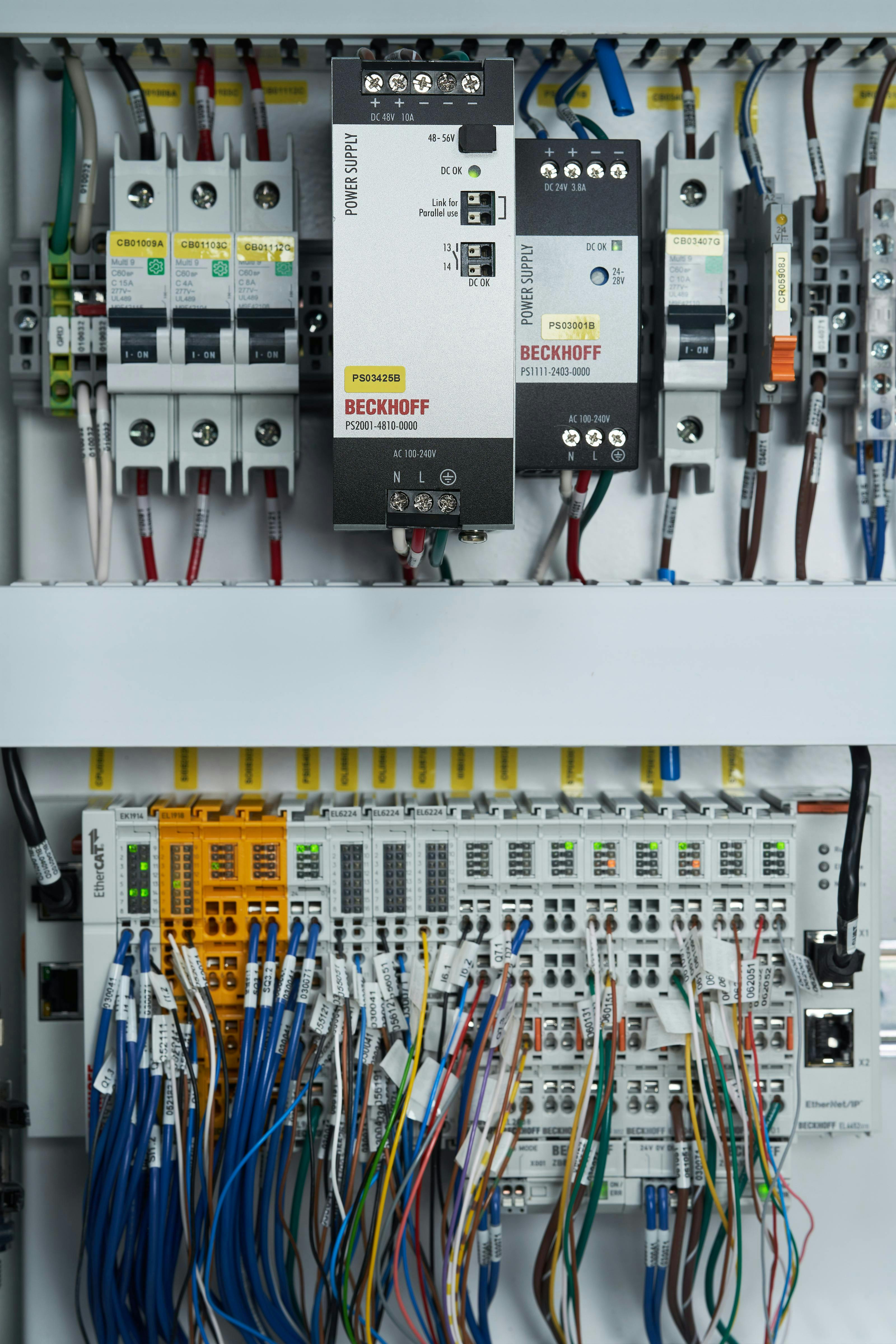

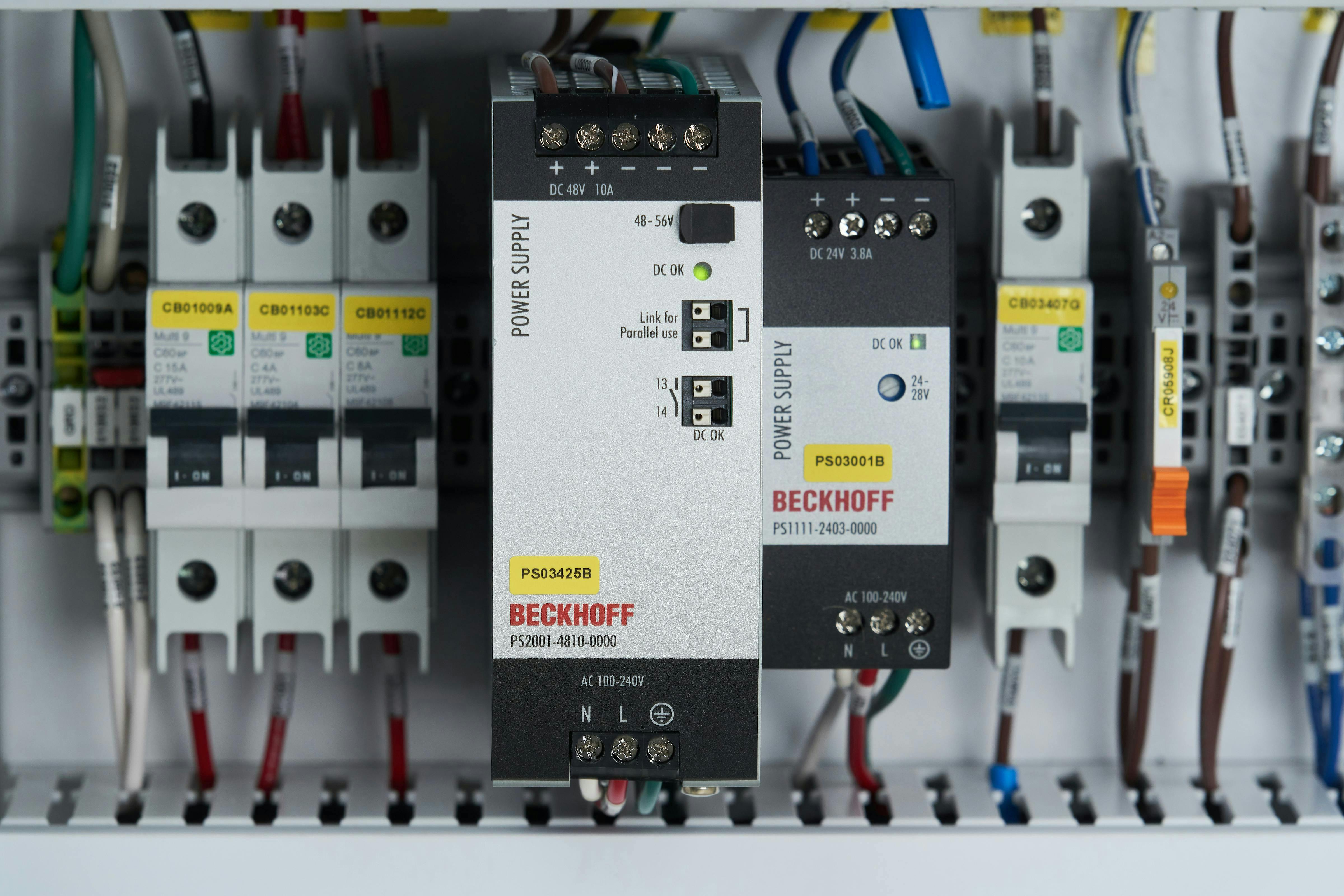

It started with our Beckhoff rack, and we kept adding more sensors and IO-Link. We had to add cards three or four times, and the Beckhoff system made it easy. That is a huge benefit in a machine that is evolving. The I/O terminals are small, so we only use about 20 mm of panel space to add eight I/Os. Motor drivers are also on the rack, so if we need another motor, we just add another card.

New automation

In 2020, we created a decision matrix comparing four control system providers. We compared all of the technologies offered, the benefits and the price, and ultimately, we decided that Beckhoff provided the best fit for the RoboTape system (Figure 3). One of the reasons we like Beckhoff is it’s easy to switch cards on the rack. It’s modular in that way.

And, for data collection, integration into the existing PC-based controller is simplified, says Lalonde.

As newcomers to Beckhoff, the engineering team was unfamiliar but excited to learn. Their day-to-day roles as custom machine builders led to tackling new technologies frequently.

"On the custom machinery side, we are driven by customer specs," says Lalonde. "At the time we had limited experience, but the team is trained on a lot of different systems and suppliers, so it was a smooth transition for them."

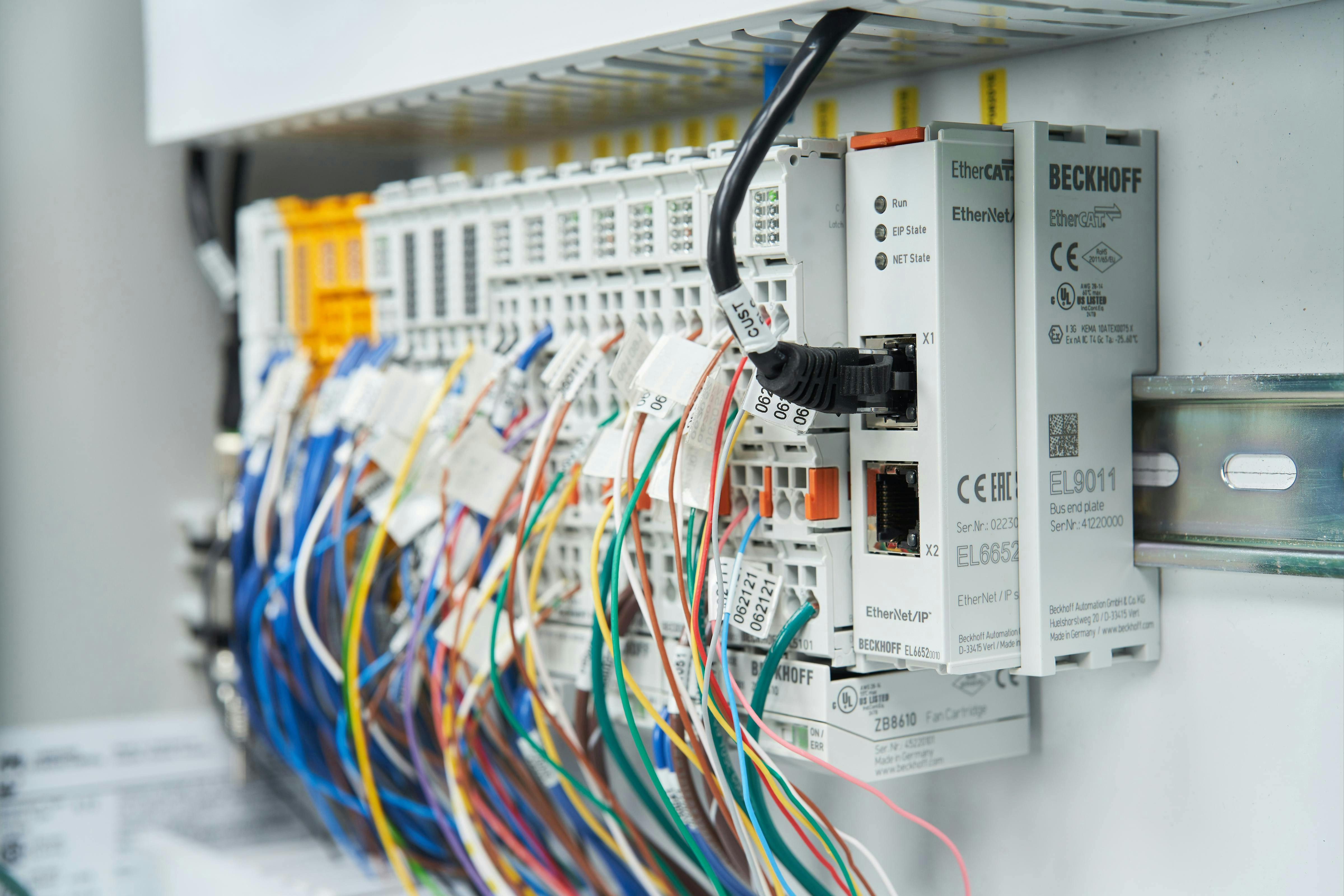

Innovative Automation worked closely with the sales and support teams at Beckhoff Canada. Regional Sales Manager Paul Pierre and Application Engineer Jim Fallowfield offered advice and technical assistance on everything from TwinCAT 3 automation software programming to EtherCAT networking (Figure 4). This helped accelerate design, commissioning and operation.

TwinCAT offers an end-to-end engineering and runtime platform for all automation functionality from PLC, safety and motion control all the way up to the Internet of Things (IoT), machine learning and simulation. With support for all IEC 61131-3 programming languages and their object-oriented extensions, preloaded or custom function blocks, and computer science standards in Microsoft Visual Studio, engineers can choose the best options based on their skillsets or, better yet, based on each application’s needs.

We use Beckhoff TwinCAT 3 software for programming. It’s integrated into Microsoft Visual Studio and feels similar for anyone who’s worked with CoDeSys. For networking, we actually allow the customer to choose. We offer EtherCAT, EtherNet/IP and Profibus. That was a selling feature to our customers.

Sean Robillard, controls department at RoboTape, appreciated this comprehensive software approach. “With a TwinCAT project, we have one folder with files for each PC-based controller,” he explains. “Within that code, we have all safety and I/O, so development of the system can be easily managed. This helps us implement different recipes, which tell the system how much tape to dispense and how quickly.”

A CP6706 economy built-in panel PC offers processing power for the application. RoboTape amped up the standard model with a dual-core Atom processor, 1-second uninterruptible power supply (UPS), 4 GB RAM and 40 GB Cfast card (Figure 5). The controller includes a 7-inch touchscreen for operator interface and is ready for cloud connectivity right out of the box (Figure 6).

“The user can view all their inputs and outputs, toggle cylinders, lights and sensors, and adjust other aspects of the machine,” says Josh Vander Doelen, project manager at RoboTape. “That’s all bundled into the same TwinCAT package, so it speeds up engineering and keeps the HMI design clean.”

The system utilizes the EtherCAT industrial Ethernet system for communication to the robot and other field devices. EtherCAT offers real-time speeds, flexible topology and up to 65,535 nodes on a single network, and it’s also open to integrating with other protocols. Beckhoff offers I/O hardware for more than 30 industrial protocols, including EtherNet/IP and Profinet, which helps the RoboTape team connect a vast range of robots and third-party devices such as sensors and encoders in customer facilities (Figure 7).

We use IO-Link sensors to gather as much data as possible. We simply add EL6224 IO-Link terminals from Beckhoff to the main I/O segment as we need more sensors. Now we can gather a significant amount of data about the machine and analyze it for actionable insights.

The sensors are quite specialized. Anything we could connect with IO-Link, we did. We were focusing on data collection and how to use that data, so 75-80% of the sensors are connected with IO-Link. The data collection system is still a beta program.

Involving the IT department to transfer and store the data presents challenges. But at some point we have to introduce them for systems operating remotely. If they have an internal server, that’s no issue. Companies already using Ignition are an even easier integration.

Ignition is an integrated software platform for supervisory control and data acquisition (SCADA) systems, developed by Inductive Automation. This software provided the ideal platform for RoboTape’s data collection system.

You can graph the ambient temperature against machine temperatures over time for identifying root failures. With Ignition, we’re using the data to improve the function of the machine. There are challenges with any data system, like setting up a remote server; there are a lot of concerns with hacking now. We can set up a server locally, as well. We’re figuring it out, it can be different with each customer.

"Sometimes we’re creating systems that could be integrating to their plantwide system already in existence," a straightforward integration, says Lalonde.

With the TwinSAFE integrated functional safety system, the RoboTape platform can protect plant personnel and equipment. The remote feeding module can enter a safe state when operators open its enclosure. A cutting blade utilized to chop the spent liner and other pinch points contained inside require guarding and protection. TwinSAFE offers safe inputs and outputs that integrators can connect directly to the door of the robot cell, light curtains or floor mats, for example.

TwinSAFE incorporates Safety over EtherCAT (FSoE) to communicate over standard networks using a black-channel approach. Safety data can travel over the same EtherCAT network, ensuring the necessary cable redundancy with no hardwiring between safety devices.

Global stick-to-itiveness

With all these technological developments, RoboTape has quickly gone global. RoboTape's overall goal is to be the global leader in the robotic application of tapes and adhesive products, explains Lalonde. "To do that, our goal is to continue to expand globally and in time expand our product offering. We accommodate different types of tapes and applications. We have the 3M version of the product, but ultimately the baseline product is brand-agnostic with tape," he says.

In addition to the unique robotic system developed for 3M, Innovative Automation has entered partnerships with distributors worldwide to handle increased demand for sales and service in other countries. "We’re approaching 100 units in the field," says Lalonde. "It is mostly Tier 1 automotive suppliers. They’re installed in Japan, the United States, Mexico and Canada.”

Innovative Automation is currently undergoing certification for CE marking in Europe and already has partners ready. "There are some minor tweaks from country to country," explains Lalonde. "There could be some labeling differences, but we’re looking for it to be 99% the same."

Our systems average eight hours of runtime before refills, but this can be even greater depending on the material. For instance, one customer processed 14,000 ft of felt on a single spool, so they're making enough parts for about 2,000 cars a day and only changing spools once a week (Figure 8). The first RoboTape systems in the field have processed more than 1 million automotive parts with only basic maintenance.

PC-based control from Beckhoff enables the systems to adapt to new products and send data to higher-level systems as needed. RoboTape plans to roll out the optional data collection system to enable users to monitor system data remotely from a customized dashboard.

Our new IoT capabilities can allow us to see which machine modes are activated and for how long. If a system is in service mode for long periods of time, it could indicate it needs maintenance or that a particular operator requires more training to meet uptime goals. We can determine the machine’s overall equipment effectiveness (OEE) and test improvements to optimize reliability.

It was vital for Lalonde and the team to select automation technology that was not just on the cutting edge, but also supported worldwide as the company expands.

“That consistent global support and availability are reasons why Beckhoff has proven to be a great choice, and we’re excited to continue working together in the future,” Lalonde says (Figure 9). “Innovative Automation has always been a leader in the industry, and, likewise, Beckhoff is constantly pushing the envelope with new technologies. That means we can keep reinventing how automation can maximize our customers’ success, no matter how challenging the application.”

About the Author

Zac Cutt

Zac Cutt is research and development group leader at Innovative Automation. Contact him at [email protected].