The HMI on the CLX represents another upgrade and ongoing development as the machine takes on more functionality (Figure 4). “For operators, it’s getting away from code-based control of a machine to on-screen graphics and simple pushbuttons,” Wilson says. “We went from a single, 20-inch monitor to two, 24-inch touchscreens from Beckhoff customized with our branding.” With cameras all over the machine and remote accessibility, CI can login to the machine and walk operators through complex processes they may not understand.

CI is also trying to generate a similar look and feel between different types of machines, so a press brake or a laser cutter have a similar operator experience. “It’s simple to teach a guy how to run a laser and then take the same guy and teach him how to run a press brake because the functions are in similar areas. It’s very simple and graphically driven,” Wilson says. “The goal is really to find ways to simplify their experience and have all the heavy lifting done by the HMI software and the PLC software behind the scenes.”

The next step for HMIs on the CLX is for the machines to self-diagnose issues with equipment or production quality. Downtime for laser machines is becoming more costly, as machines run faster, and fewer operators produce increased capacity. “Where maybe a laser was feeding five or six press brakes and welding on down the line, today it’s maybe only feeding one or two,” Wilson says. The ability of machines to self-diagnose problems is key, and even more importantly, when it’s running lights out in an automated cell, it can identify an issue, continue to run at a reduced capacity and still make parts. It sends out emails to alert personnel and raises the flag, saying it needs some help. “That is a giant jump forward technologically,” Wilson says.

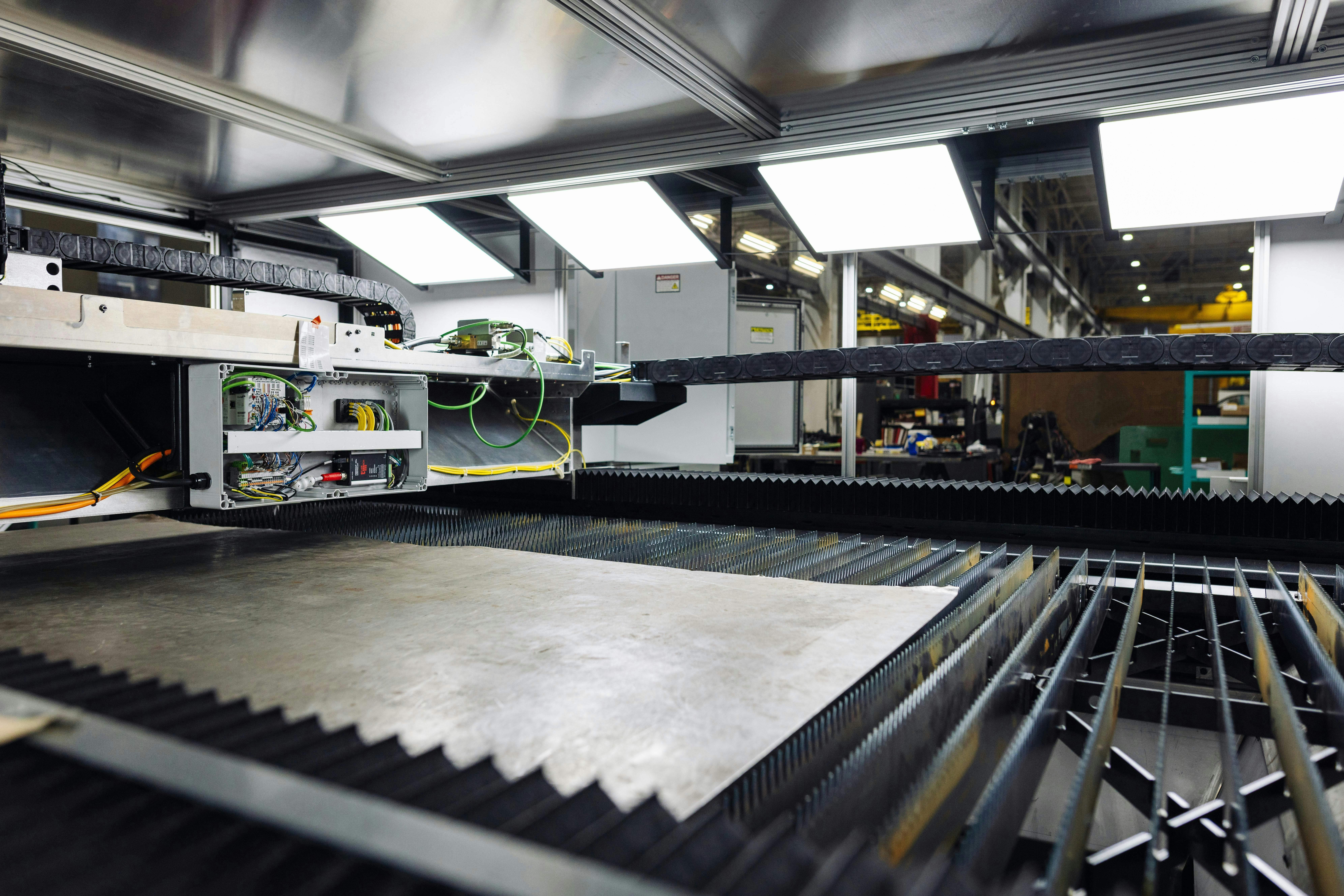

As an example of where CI is headed with lights out operations and maintenance monitoring, the machine uses an automatic nozzle changer (ANC). The copper nozzle is the piece through which the laser beam travels and is the transition point between the beam and the cutting process. “The nozzle changers really help address customer requirements in the advent of running unattended,” Wilson says, in combination with high-mix parts manufacturing. It could be a single nozzle or a double, pumping nitrogen, oxygen or a mix of gases between nitrogen and oxygen, high pressure and more. Operators used to manually change nozzles, but the ANC automates this process.

It also plays a role in inventory management. In the past, operators could set up a laser machine to produce thousands of one part, running for days and stockpiling large inventories. “The cost of that and the sheer volume of money that’s wrapped up in one product is untenable in today’s environment,” Wilson says. “Where you used to make 1,000 parts a month, now you’re maybe making 10 a day, and you’re feeding that line more of a just-in-time level of output.”

For that varying product, the CLX machine will automatically determine the right nozzle depending on thickness, material and what is needed downstream and will automatically change to the correct nozzle. “The other advantage is there’s a lot of equipment and technology that we can add via EtherCAT, to look at what’s going on in the cutting process and realize we’re potentially having an edge degradation problem. If the nozzle gets damaged to the point where the assist gas is not coming out in the right cone shape, you may see degradation and edge quality moving in X or Y,” Wilson says. Modern machines can now sense that degradation and automatically replace the nozzle, clean it or recalibrate it and go back to work. “It’s really all about being able to change equipment and materials on the fly very quickly,” Wilson says.

Maintenance extends much further than the nozzles and will continue to grow in the future. “The cameras that we’re working on right now are part of active vision systems that monitor the whole machine, and when there’s a fault or an error, it’s event logging the video, all that data that was gathered, all the key components of the machine, it’s all being logged. Think of it like a black box recorder in an airliner,” Wilson says. Maintenance operators can easily determine exactly what went wrong and when.

The vision technology works hand-in-hand with the diagnostics in EtherCAT. Meanwhile, the CLX provides functional safety via system-integrated Safety over EtherCAT (FSoE) technology, a “black channel” solution that communicates safety data over the standard network. “In the old days, all the safety interlock components tended to be in a series, because the circuits were so expensive to make. Almost everything that’s done now on the Beckhoff side, essentially home-runs every interlock and safety circuit through the fieldbus, without having to hardwire every safety device back to the controller. So you know exactly what individual event happened.” Prior to that, it could take days to isolate an incident and know exactly what happened.

Machine monitoring and maintenance services are a growing business objective for CI. Given the data about how many rotations, for example, a part has made, CI can mathematically determine maintenance needs and apply those in a screen within the HMI. “Whatever the limitation of that particular component, we can link that to a maintenance item, including vibration sensors that are monitoring gearboxes and motors that can tell us vibrations are increasing,” Wilson says. “Most of it right now is control-based and stays at the control level, but the industry is driving toward feeding all that to cloud-based systems where the service manager or vendors’ services teams are scheduling service based on the data they’re getting from actively running machines.”

The big hold-up to advancing that technology right now, considering the requisite internet and Wi-Fi connectivity, is security. “Remember, I was talking earlier about those IT guys. The second you tell an IT guy that the machine could talk to somebody outside of their building, he starts sweating. So the technology that can help isolate that and safely communicate how their business is running outside the factory walls, I think is really the next advancement we’re going to see in our industry,” Wilson says.

CI will continue to expand and iterate on the CLX machine with a newer version expected in late 2025. For the future, CI is also working on robotics in the press brake side and on the laser side. “The next big connection in my mind is the handoff between the two machine types, whether that’s using AGVs, whether it’s using conveyor systems, whether it’s going into a tower system, then that tower system has brake assemblies with robotics further down that tower like a warehouse environment. Those parts are delivered via the towers to the next operation and out they go. All of that is what’s coming,” Wilson says. “For us, it’s simply another EtherCAT connection to another module that’s going to make it all work.”