Lost in our age of microprocessors is the importance and need to still operate equipment using hardwired switches mounted in panels. In some cases, these are critical controls related to safety systems that serve as a backup to microprocessor-based control. Improper operation of these panels can have significant safety, environmental and equipment integrity consequences.

Despite their importance, hardwired panels usually get very little review from a human-factors perspective. While the panel should be designed reflecting its intended use, there are some basics in panel-layout design that enhance usability. These basics involve how we humans are wired to process information. By matching the layout to our inherent processing characteristics better, an easier-to-use design is created.

Two basic techniques for improving panel layout are demarcation and hierarchical labeling. Demarcation aids information processing by breaking the interface into chunks, so that it becomes easier to process. Human short-term memory, our conscious processing, is a capacity-limited system. We can handle about seven chunks of information. Demarcation, placing boxes or lines around related items, reduces the information processing demands by allowing all of the controls and displays with the lines or box to be processed as a chunk. Hierarchical labeling aids information processing by matching the hierarchical manner in which we humans store information. Once a major section has been identified and labeled, that information need not be repeated on labels within that section or subsection. Creating master labels that eliminate the need for repetition on individual labels enables use of larger fonts to increase legibility. Information transfer, bits per square inch, is increased. Operator scan time is reduced as each label need not be inspected to place the switch or light into context as to its function and use.

Consider the case of an emergency isolation panel for a process with a highly toxic catalyst. The original design was an 8-by-16 array of push buttons. The same controls were used, even though different functions were being performed: (1) initiation of a program and (2) opening/closing of a valve. There was some minor demarcation, with the panel broken into three, albeit oddly shaped areas. Making sense of the panel requires considerable inspection to understand the controls and indicators.

An examination of the groups revealed additional opportunities for grouping, which then enabled use of more hierarchical labeling. However, to make clean groups, the panel did not have enough available space with the controls slated for use. Since the panel size could not be changed, the alternative was to use different controls. Since the valve controls were binary in nature (open/close), rotary switches could be utilized that enabled the same function to be performed in half the space. The result is the panel in Figure 2.

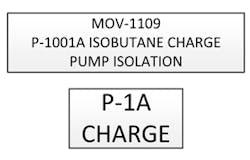

The redsigned panel can quickly be processed at a single glance. The panel has been segregated both horizontally and vertically. It is clear which controls are for valves and which are for initiation of a program. The user can quickly focus on the section of interest to them without being distracted by the other sections. The demarcation and hierarchical labeling enables the user to identify the sections of interest and ignore those that are not. Reading each label is not necessary to understand the functions that will be impacted by each section. The change in the individual labels is seen in Figure 3. The switch number has been removed, and the label matches the nomenclature the operators use for the equipment. The function of the switch and the system to be affected are handled by the section labels. The font is approximately two-thirds larger, enabling identification from farther away or with less illumination.

ALSO READ: You might have HMI design backward

Hardwired panels often serve critical-safety, environmental and asset-protection functions. Ensuring their proper use requires they be designed with human factors in mind. Two basic techniques to ensure easier use are through demarcation and hierarchical labeling. While these should not be the only human-factors design principles to use, they are a definite start. Both enable faster processing of how to interact with the panel and allow for greater rates of information transfer.

David A. Strobhar, PE, is one of the founders of the Center for Operator Performance (www.operatorperformance.org) and principal human factors engineer at Beville Engineering in Dayton, Ohio. Contact him at [email protected].