How to standardize visualization technologies for machine efficiency

Manufacturers have realized the importance of embracing flexible, standardized technologies within their operations. By adopting such systems, they access a broader pool of technical talent and ensure easy scalability, transferability and replicability across multiple plants.

Proprietary systems pose significant risks to rapid upgrades and expansions to maintain competitiveness. Challenges frequently arise related to technical expertise for customization, vendor consolidations that obsolesce product lines and long-term maintenance costs.

Employing a scalable system built on standard technologies like HTML5, Javascript and SVG images while avoiding proprietary networks or technologies lowers costs and mitigates risks. Embracing industry-standard technologies not only boosts efficiency, but also safeguards against disruptions stemming from changes in the business landscape beyond one's control. Proactive consideration and planning for future maintenance and growth in engineering and machine software are pivotal to maximizing uptime and minimizing costs.

Visualizations drive efficiency

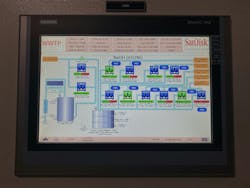

Unifying the visualization system across machine design, machine operation, reporting and simulation, with integrated cybersecurity, delivers process efficiency and flexibility for any manufacturer. With shifting customer requirements, manufacturers must be agile to maintain competitive advantage. Implementing a unified software to provide operational consistency, transferability and reliability can deliver direct improvements at all levels.

HMI and visualizations allow manufacturers to oversee and control operational costs while managing intricate processes. Proprietary visualization system technologies constrain compatibility for integration and scalability. These closed systems necessitate costly specialist expertise to tailor to specific applications and often were only easily customizable by the machine builder, leading to increased expenses and downtime for any modifications. The prerequisites for visualization solutions are rigorous: they must offer swift response times, ideally adapt to various end devices and boast user-friendly interfaces.

Simulation and visualization are crucial to increasing plant efficiency. Simulation has become standard across many industries for plants, lines or individual machines as part of the design and operations process. Machine designers must deliver the correct data at the right time to the right person for visualizations and simulation to increase efficiency.

When improving processes, updating or expanding lines or switching raw materials or finished product specifications based on shifting demands, updating the critical data tracked and the visualizations that make that data easily consumable are requirements. A system based on standardized technologies, such as a browser-based platform using HTML5, Javascript, and SVG images, streamlines the customization of data visualizations, HMI systems' scalability and data sharing across interconnected systems. Implementing simple drag-and-drop systems for creation, customization and configuration based on these technologies is cost-effective in meeting new requirements.

Process consistency through standardization

When there is internal demand for HMI and visualizations for monitoring machines, plants and groups of plants at all levels, manufacturers need technologies built to support their requirements. Modern plant efficiency requires mobile apps for remote monitoring and device configuration. The dynamic customization of visualizations to meet requirements may also require extensive cost and time to implement to deliver the necessary functionality.

Industry-standard technologies help manufacturers future-proof solutions to maintain the flexibility to fulfill current requirements and dynamic and emergent needs. These technologies ensure stakeholders work together efficiently through all stages, from design to operational reporting. Working in a unified system at all levels also means standardization and transferability of solutions and KPI visualizations to various levels within or across plants. This also eliminates the risk of data being lost moving between disparate systems for design, operations and reporting.

Industry-standard toolsets for customization of HMIs and interfaces with web-based architecture employ technology that benefits from the improvements gleaned with widespread use across the commercial marketplace. As opposed to proprietary technologies that require specialized consultation or experts from a small subset of manufacturers, HTML5 and Javascript knowledge needed for customization is widely available in the labor force.

This same technology enables universal compatibility, including cloud environments and mobile devices, while leveraging object-oriented engineering with hierarchical asset structures. They also ensure compliance with industry-standard cybersecurity measures as part of the bridge between IT and OT.

As manufacturers’ needs and the demands of their customers become more dynamic, planning for future changes and scalability becomes increasingly important. Choosing the right technologies and toolsets is a critical aspect of ensuring that when new requirements arise, manufacturers can quickly adapt and compete. Minimizing customization and expansion costs while allowing for quick shifts in production setup will only become more vital for manufacturers as time goes on.

Kyle Harrison is HMI product manager with Siemens North America. Prior to Siemens, Kyle worked with B&R Industrial Automation and Intertek. Contact him at [email protected].