Operator Interface in Hazardous Areas

Machine and robot builder OEMs sometimes design their products and systems for installation in their customers' hazardous areas. This entails special design considerations, particularly for operator interface components, because these items are exposed directly to the area's volatile environment.

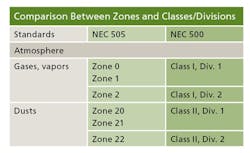

NEC classifies hazardous areas as shown in the table. Division 1 designates an environment where hazards are likely to exist under normal operating conditions. Division 2 is an environment where hazards are not likely to exist under normal operating conditions. Designing systems for use in Division 1 is much more demanding than designing systems for use in Division 2.

NEC 505, the IEC/CENELEC approach, uses three zones instead of two divisions. A Zone 0 location is "an area in which an explosive gas atmosphere is present continuously or for long periods." A Zone 1 location is "an area in which an explosive gas atmosphere is likely to occur in normal operation." A Zone 2 location is "an area in which an explosive gas atmosphere is not likely to occur in normal operation, and if it does occur, is likely to do so only infrequently and will exist for a short period only."

The easiest way to provide safety in hazardous environments is via a touchscreen LCD interface. "Peripherals like traditional keyboards and other mechanical pointing devices are normally unwelcome in the more harsh process environments, with touchscreen technology offering both a more convenient and cost-effective alternative," says Kristen Barbour, product marketing manager at Pepperl+Fuchs (www.pepperl-fuchs.us).

A touchscreen LCD can be safely installed in a hazardous area in one of two ways. The first is with non-rated components in a purged enclosure or an explosion-proof housing, and the second is with components rated for use in the hazardous area.

[pullquote]"With a purge system, the ambient atmosphere is removed from the housing by an initial purge process," Barbour explains. "After the purge phase, sufficient compressed air or inert gas is supplied to compensate for leaks in the enclosure. This permanent overpressure prevents any ambient air from entering the enclosure. A purge system, and the housing of an operator workstation, creates a safe environment for all components housed with the enclosure. But purging alone does nothing to keep touchscreens safe in Division 1 installations. This requires an industrial monitor with an IS (intrinsically safe) or Division 1 touchscreen."

For Division 1, purged enclosures or explosion-proof housings are the only practical option because no operator interface vendor supplies off-the-shelf hardware suitable for direct installation in these areas. For Division 2, there are many operator interface options. Common to all of these options is that the hardware supplied isn't capable of igniting the gases, vapors or dusts present in the particular hazardous atmosphere.

A vendor can supply its operator interface hardware in an enclosed housing that's certified for use in Division 2. Alternately, a vendor can supply operator interface components that are intrinsically safe. IS components emit minimal amounts of electrical and thermal energy, always low enough that ignition of the hazardous atmosphere can't occur.

"Simatic HMI Panel PC Ex and HMI Thin Client Ex are fully enclosed operator interfaces and are available for both hazardous zones 1/21 and 2/22 environments," notes Sidney McLaurin Jr., product manager for industrial PCs and PC-based automation at Siemens Industry (www.siemens.com). "A fully enclosed design permits these HMIs to be installed in hazardous locations, allowing a full industrial PC HMI within a hazardous area. Both the product lines include an exterior design that meets IP66 environment ratings for the front panel and IP65 for the rear panel.