Global robot density nearly doubles, IFR reports

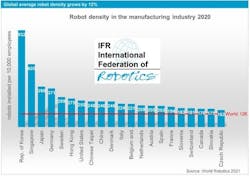

The top 5 most automated countries in the world are: South Korea, Singapore, Japan, Germany, and Sweden.

The use of industrial robots in factories around the world is accelerating at a high rate: 126 robots per 10,000 employees is the new average of global robot density in the manufacturing industries – nearly double the 66 units per 10,000 employees from five years ago. This is according to the 2021 World Robot Statistics, issued by the International Federation of Robotics (IFR).

By regions, the average robot density in Asia/Australia is 134 units, in Europe 123 units and in the Americas 111 units. The Top 5 most automated countries in the world are: South Korea, Singapore, Japan, Germany and Sweden.

“Robot density is the barometer to track the degree of automation adoption in the manufacturing industry around the world,” says Milton Guerry, president of the International Federation of Robotics.

Asia

The development of robot density in China is the most dynamic worldwide. Due to the significant growth of robot installations, the density rate rose from 49 units in 2015 to 246 units in 2020. Today, China’s robot density ranks ninth globally compared to 25th five years ago.

Asia is also the home of the country with the world´s highest robot density in the manufacturing industry: the Republic of Korea. The country’s robot density exceeds the global average seven-fold (932 units per 10,000 workers). Robot density had been increasing by 10% on average each year since 2015. With its globally recognized electronics industry and a distinct automotive industry, the Korean economy is based on the two largest areas for industrial robots.

Singapore takes second place with a rate of 605 robots per 10,000 employees in 2020. Singapore’s robot density had been growing by 27% on average each year since 2015.

Japan ranked third in the world. In 2020, 390 robots were installed per 10,000 employees in the manufacturing industry. Japan is the world´s predominant industrial robot manufacturer. The production capacity of Japanese suppliers reached 174,000 units in 2020. Today, Japan´s manufacturers deliver 45% of the global robot supply.

North America

Robot density in the United States rose from 176 units in 2015 to 255 units in 2020. The country ranks seventh in the world – ahead of Chinese Taipei (248 units) and China (246 units). The modernization of domestic production facilities has boosted robot sales in the United States. The use of industrial robots also aids to achieve decarbonization targets.

Several car manufacturers have announced investments to further equip their factories for new electric drive car models or to increase capacity for battery production. These major projects will create demand for industrial robots in the next few years.

Europe

Europe´s most automated country is Germany - ranking fourth worldwide with 371 units. The annual supply had a share of 33% of total robot sales in Europe 2020, and 38% of Europe’s operational stock is in Germany. The German robotics industry is recovering, mainly driven by strong overseas business rather than by the domestic or European market.

Robot demand in Germany is expected to grow slowly, mainly supported by demand for low-cost robots in the general industries and outside traditional manufacturing.

France has a robot density of 194 units (ranking 16th in the world), which is well above the global average of 126 robots and relatively similar compared to other E.U. countries like Spain (203 units), Austria (205 units) or The Netherlands (209 units). E.U. members like Sweden (289 units), Denmark (246 units) or Italy (224 units), have a significantly higher degree of automation in the manufacturing segment.

As the only G7 country – the United Kingdom has a robot density below the world average of 126 units with 101 units, ranking 24th. Five years ago, the UK´s robot density was 71 units. The exodus of foreign labor after Brexit increased the demand for robots in 2020. This situation is expected to prevail in near future, the modernization of the U.K. manufacturing industry will also be boosted by tax incentives through March 2023, in which companies can claim 130% of capital allowances as a tax relief for plant and machinery investments.